More and more parcels, rapidly changing formats, less and less time: The demands on logistics sorting systems and equipment in retail and in parcel centers are increasing rapidly. This development is being fueled by high growth rates in e-commerce worldwide. Market players require fast, high-throughput, and freely scalable sorting and distribution systems to deliver peak performance in this environment. How can these be implemented efficiently and precisely? With innovative automation solutions from Beckhoff.

Your automation platform for powerful sorting systems:

- Everything from a single source – from fieldbus technology and suitable industrial PCs to leading automation and control software and innovative transportation solutions.

- World leader: Beckhoff sets the standards in intralogistics with innovative automation solutions. This applies to EtherCAT in the context of fieldbus technology as well as PC-based control or the MX-System for control cabinet-free automation.

- Modular and scalable: All technologies are modular, coordinated with each other, and flexibly combinable as standard for powerful sorting systems with future potential that can be configured as required.

All your advantages with Beckhoff at a glance

EtherCAT: The leading fieldbus technology

Sorting and distribution systems are linear in design, requiring fieldbuses in line topology. Conventional, switch-based technologies are severely limiting because there are delays at every switch as Ethernet frames pass through. When connecting in series, the limit is eight devices. EtherCAT from Beckhoff operates without switches and processes the frames in a continuous process, without limits, and in real time without delays.

EtherCAT highlights

- extremely fast: with cycle times of up to 31.25 µs at 100 nanoseconds accuracy

- freely scalable: EtherCAT allows deterministic real-time control of up to 65,535 field devices in series (line topology)

- integrated safety: provided byFunctional Safety over EtherCAT (FSoE) for high safety requirements up to SIL3, CAT 4

- integrated cyber security: malware is usually spread via the Internet Protocol (IP). EtherCAT does not use this, thereby differing from other fieldbus systems

- ready for more: large bandwidth for diagnostic data enables predictive maintenance, artificial intelligence (AI), and machine learning (ML)

Which advantages does EtherCAT offer as a fieldbus in sorting applications?

More and more parcels, rapidly changing formats, less and less time: high-performance and fast sorting systems are essential for modern warehouse and distribution logistics. But what role does the fieldbus actually play in this? Our industry expert Doug Schuchart answers this question at Logimat 2025.

TwinCAT: the automation software

Sorting systems in retail and logistics centers are networked and highly automated. To build up the necessary control intelligence, you need an integrated software platform that is optimized for all tasks ranging from engineering to runtime. With TwinCAT, Beckhoff developed this automation platform more than three decades ago and established PC-based control.

TwinCAT highlights

- automated integration: TwinCAT transforms almost any PC-based system into an integrated controller with multiple runtime systems from PLC to robotics

- comprehensive networking: TwinCAT supports the integration of warehouse execution systems, databases, and cloud environments

- systematically open: TwinCATspeaks the standard programming languages, masters all other Ethernet technologies in addition to EtherCAT, and is open for the integration of third-party components

- functional and modular: with more than 100 function modules ranging from motion control and measurement to vision, TwinCAT is inherently modular and scalable

- flexible from the ground up: this starts with the operating system – TwinCAT runs equally well under Windows or Linux®

Tailor-made PC performance

The complexity of advanced sorting systems is developing just as dynamically as the growth in e-commerce. Overall systems can hardly be mastered with classic PLC hardware. The solution of choice is therefore PC-based control from Beckhoff – implemented with industrial PCs configured on a system-specific basis, the latest processors, and an operating system of your choice.

Highlights of the scalable PC portfolio

- All types of industrial PCs: You have the choice between powerful industrial PCs, embedded PCs for space-saving installation on DIN rails, control panel PCs, and stand-alone panel PCs.

- State-of-the-art processors and memory: The spectrum ranges from Intel® Celeron® to Core™ i7 and includes memory and mass storage for all performance requirements.

- Free choice of operating system: from Microsoft Windows to Linux® with Secure Boot.

- Unlimited number of connections: one PC-based controller for all EtherCAT devices.

- Maximum individuality: customer-specific mechanics, electrical components, software, and designs.

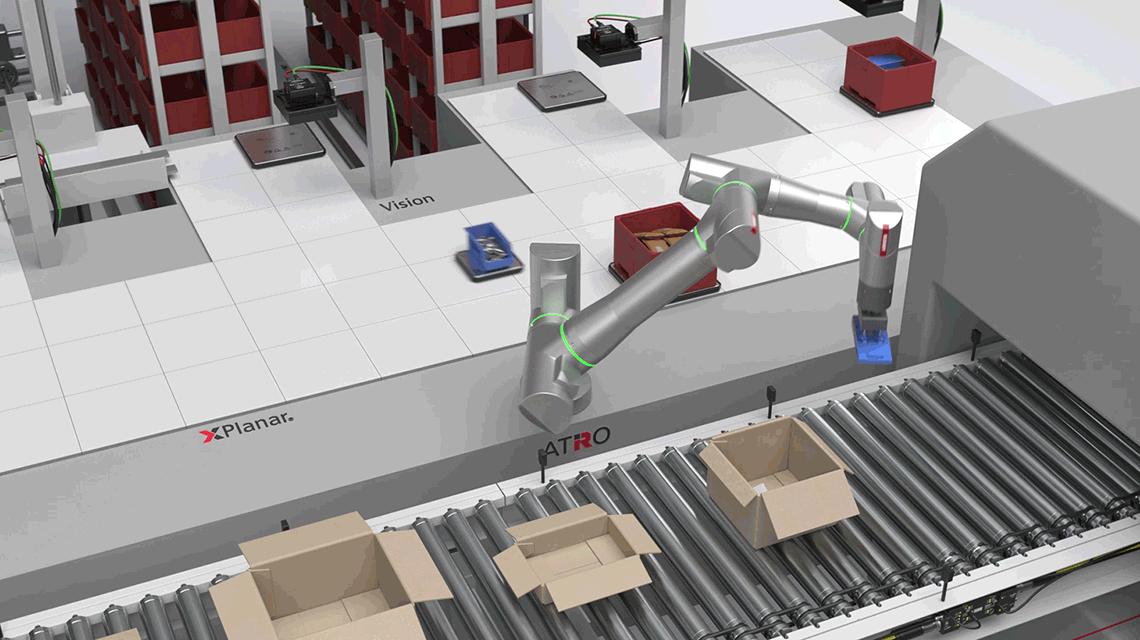

Revolutionizing the flow of goods

Conveyor belt systems are the standard solution for product transportation in intralogistics. However, they present several disadvantages. They are rigid systems which move products at a fixed distance from each other at the same speed. This is the complete opposite of flexible. They are also mechanical systems which are prone to wear and therefore require intensive maintenance. With XTS and XPlanar, Beckhoff offers two intelligent mechatronic alternatives for product transport.

XTS

- How it works: Magnetically driven movers move along a travel path which consists of freely combined XTS motor modules. The movers are controlled individually.

- fast and dynamic: XTS stands for fast product transport with dynamic, individual motion profiles that can be varied on a part-specific basis

- new and very economical: now also available as XTS Eco-Line.

XPlanar

- How it works: XPlanar consists of stationary, energized XPlanar tiles over which the XPlanar movers – which are equipped with permanent magnets – move.

- Full freedom of movement: XPlanar tiles can be laid out in any path configuration. The movers move freely above it, transporting goods from A to B.

Control cabinet-free automation with the MX-System

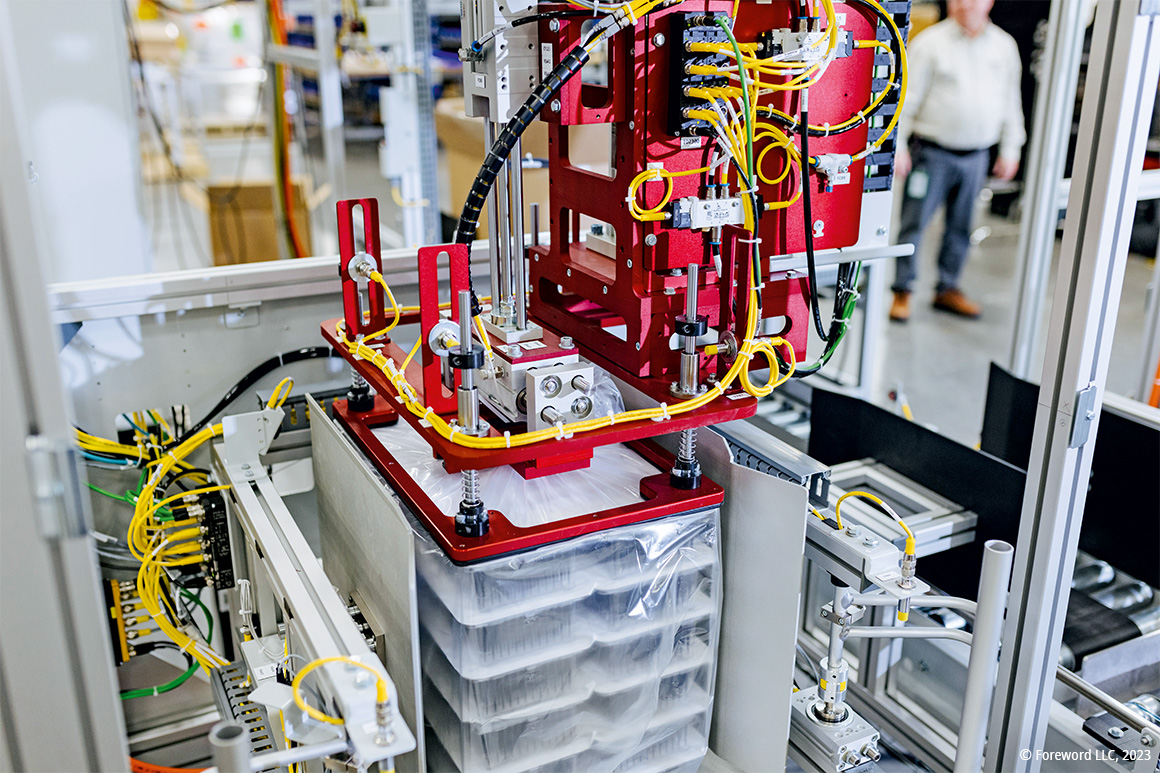

As the length and size of sorting systems increases, so does the number of field devices. For central control cabinet designs, this leads to a massive increase in automation costs. The wiring process becomes more time-consuming, cable runs grow longer, control cabinets increase in size and require more and more space. This is why Beckhoff is now launching the MX-System, a revolutionary solution for control cabinet-free automation. Combined with our IP67 EtherCAT Box modules and other components, it creates fully decentralized automated systems.

Highlights of the MX-System

- Decentralized integration: The MX-System consists of a baseplate with slots and a modular system with function modules. The baseplate is integrated directly into the system’s installation space, ensuring short distances and eliminating the need for a control cabinet.

- Plug-and-play installation: Each MX module is a functional unit that is ready for installation. It is simply plugged onto the baseplate and screwed tight. Done!

- Modular right down to the electrics: With the MX-System, sorting systems are now consistently modular both in terms of design and electrical components.

- Complete and robust: The modular system covers the entire range of tasks for intralogistics systems. All MX modules meet the requirements of protection classes IP65 or IP67.

NPI

Upgrades to the automation reduce the sorting system wiring by 50% and cut costs by a three-digit figure: NPI’s singulation and sortation solutions, which leverage Beckhoff controls and EtherCAT, help a California distribution center reduce difficult-to-fill labor requirements while increasing throughput and decreasing turnaround times.