Headquarters United Kingdom

Beckhoff Automation Ltd.

+44 1491 4105-39

info@beckhoff.co.uk

www.beckhoff.com/en-gb/

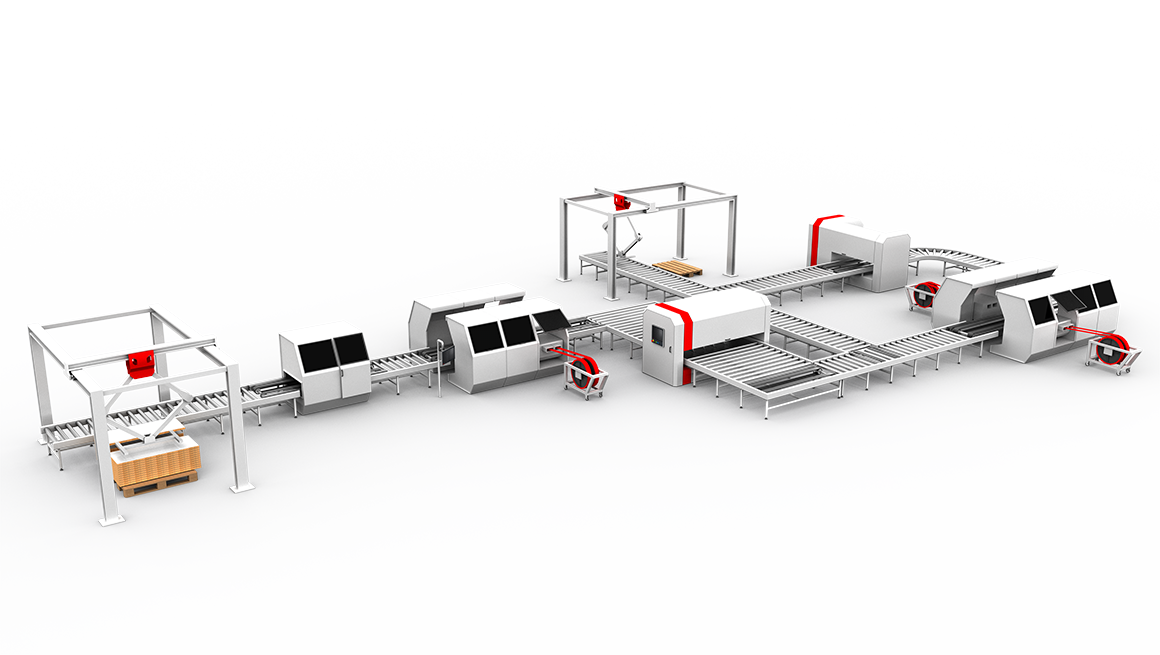

PC-based control is ideally suited to the complete automation of many different processes in the wood industry. The bandwidth of solutions ranges from complete sawmills to individual machines for joiners and smaller businesses, and even fully automated furniture production with interlinked systems consisting of transport, feeding/stacking, edge processing, CNC machining, and surface treatment. PC-based control – our drastically simplified control structure combined with the consistent use of IT standards – meets the demand for maximum part throughput with a high degree of individualization, fulfills the highest quality requirements, and responds to intense cost pressure. Fast and high-performance control technology from Beckhoff ensures that our furniture manufacturer customers and their machine building partners are well-equipped to tackle the challenges they face.

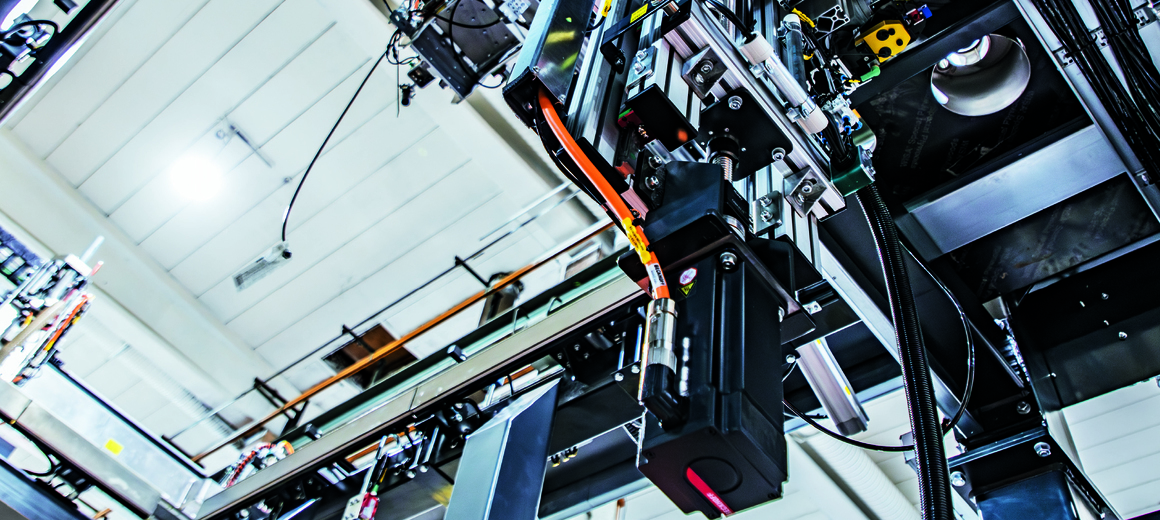

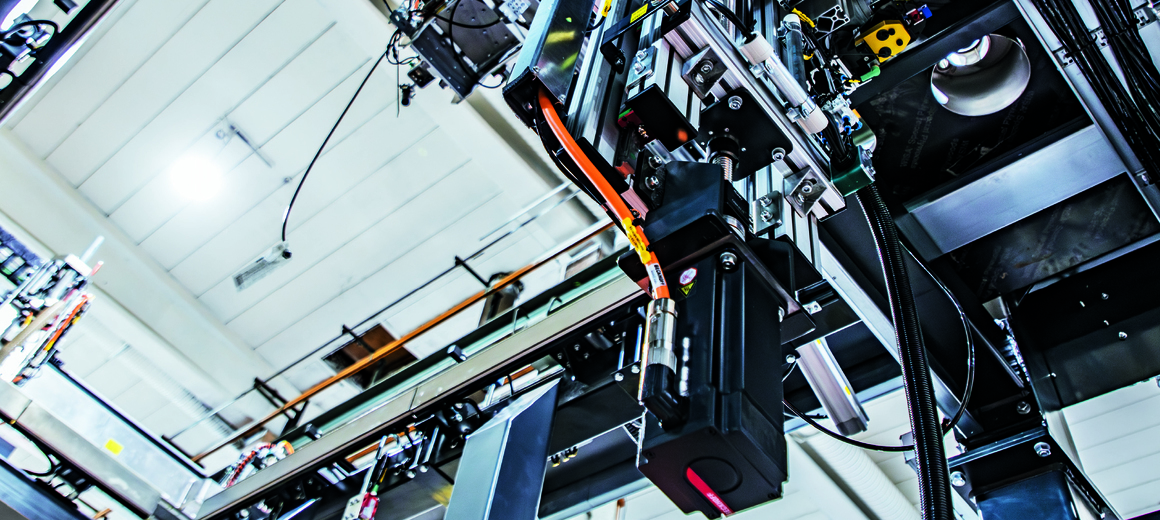

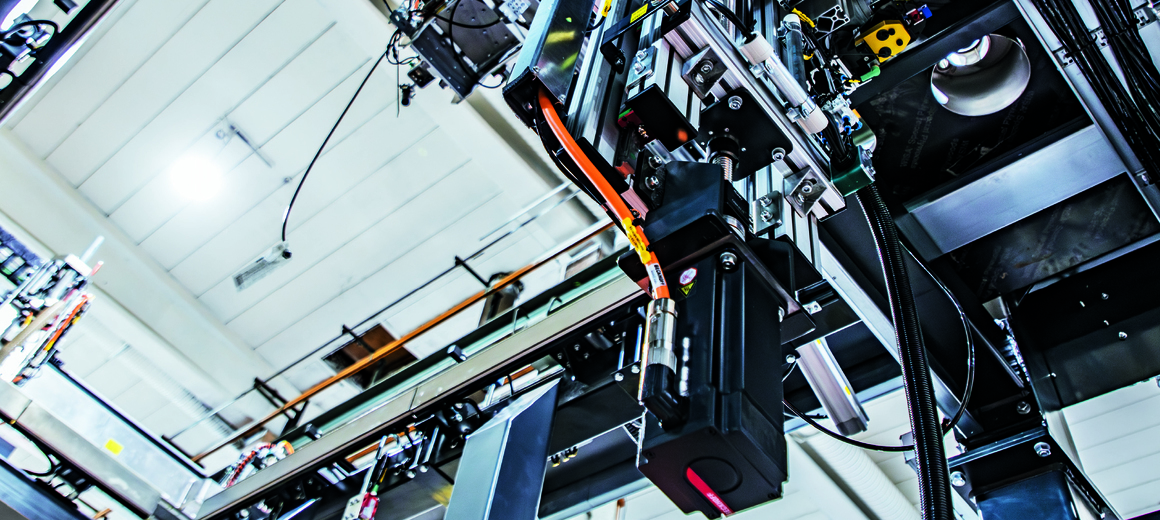

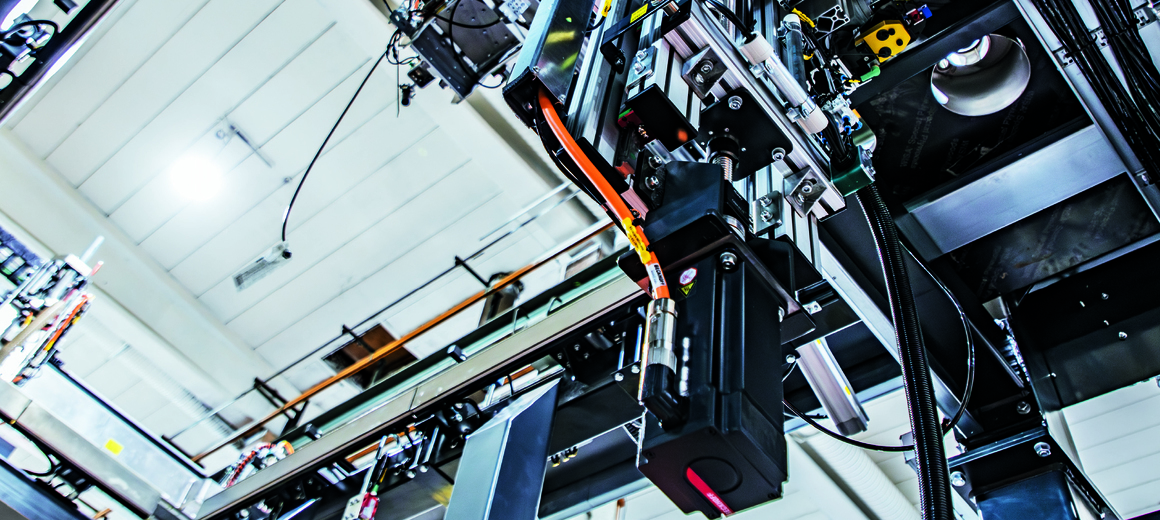

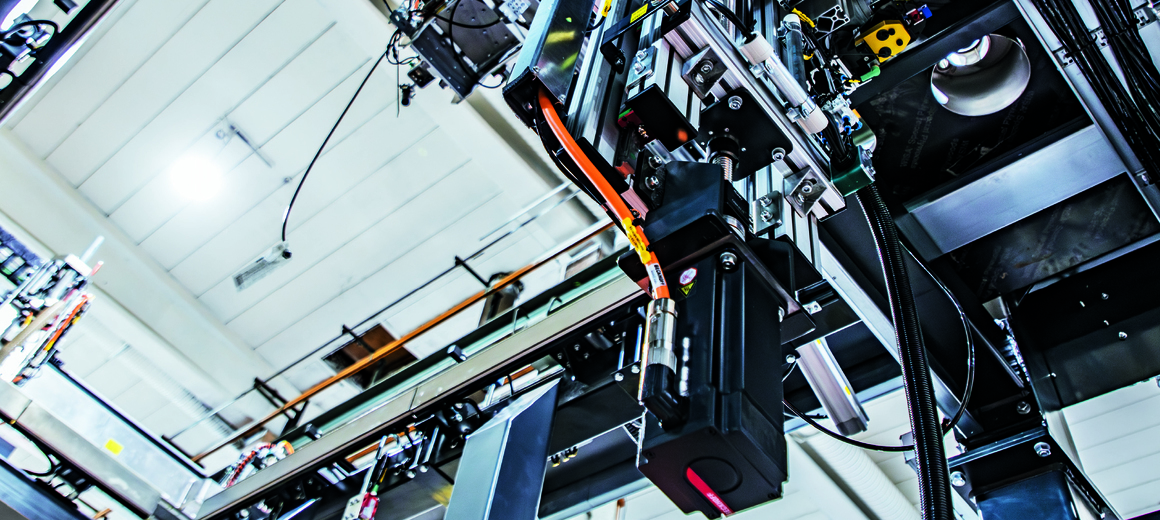

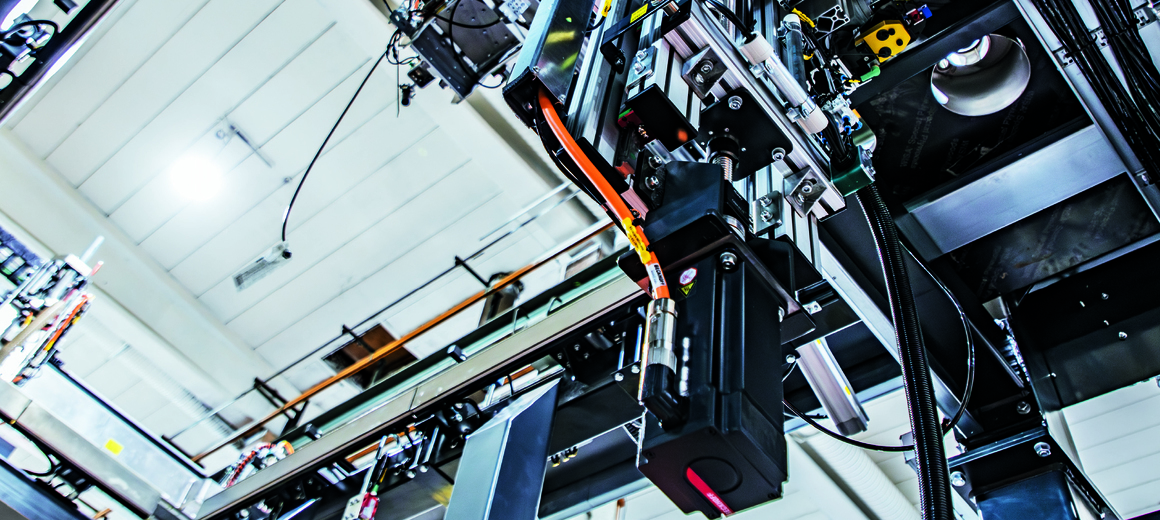

Wood is a natural and renewable raw material, which means it rarely arrives in pristine condition. This is why the Finnish company Raute, which claims to be the global market leader in veneer, plywood, and LVL (laminated veneer lumber) production technology, also offers repair systems that automatically detect and repair defects. A combination of AL8000 linear motors and AX5000 servo drives from Beckhoff ensure the necessary high precision and dynamics.

The new C6025 IPC is an ideal choice for demanding control applications where green, sustainable IT is also a requirement.

At Ligna Beckhoff showed the complete tool chain of PC-based automation technology, which is optimised both for the control of individual machines and for complete factory automation in the woodworking and processing industry.

The compact AX8000 multi-axis system enables high-precision positioning and machining processes in extremely short control cycles. Already integrated: TwinSAFE Logic with 16 drive-integrated safety functions.

The new generation of safety controllers from Beckhoff provide consistent modularity and scalability.

Smart machine functions for TwinCAT Vision and TwinCAT Speech