PC-based control in a ring sawing machine for the watch and jewelry industry

The mySaw automated ring sawing machine from Carl Benzinger proves that even small systems – which make even smaller end products – can be full of high-tech features. The end-to-end control system from Beckhoff not only provides the high level of system flexibility required in the jewelry sector, but also integrates powerful quality inspection with the seamlessly integrated vision and machine learning solutions.

Carl Benzinger GmbH specializes in highly precise, automated CNC turning and milling machines and produces them entirely at its German headquarters in Pforzheim. Lathes for the automotive, precision mechanics, optics, watches and jewelry, and aerospace sectors make up the majority of the machines. Sascha Jentner, Application Technology and Technical Sales Jewelry Machines, explains: “Industrial machines are usually complex and automated to produce specific components. In the jewelry sector, it is more about a particular product, such as a ring, which will be manufactured in an extremely wide range of variants – depending on the ring size and width or material or alloy type. This diversity makes jewelry machines highly individual and sophisticated.”

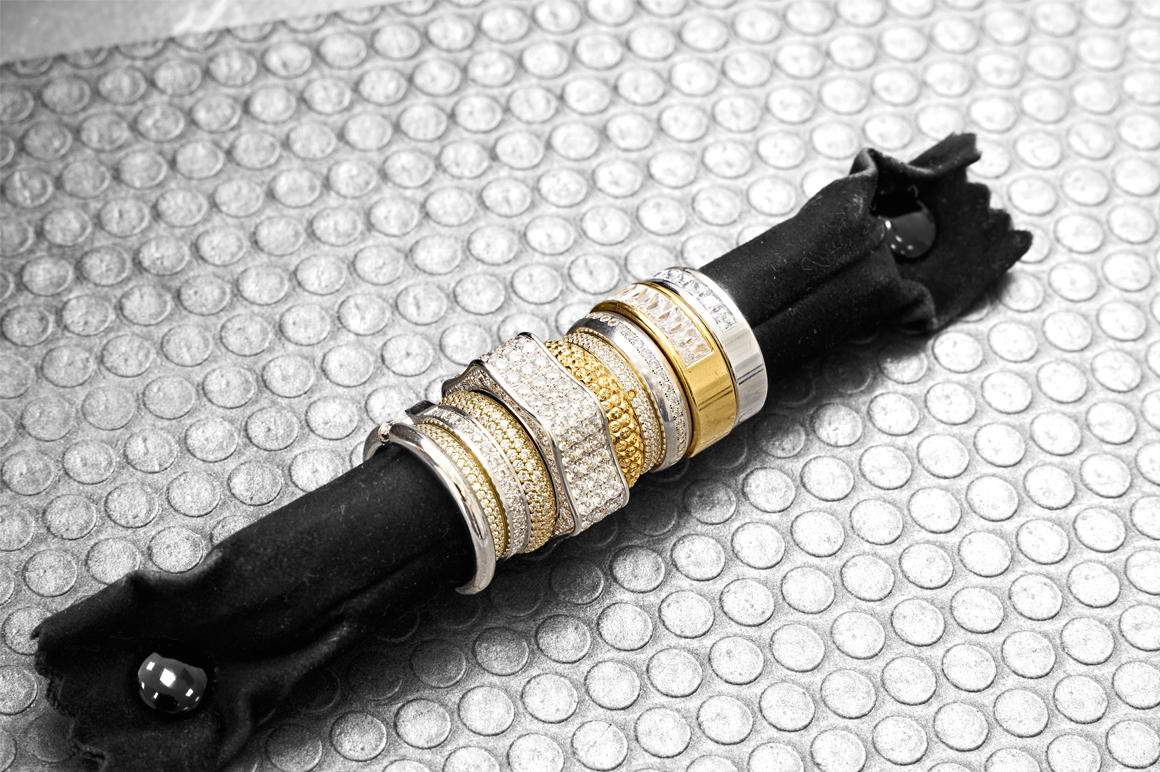

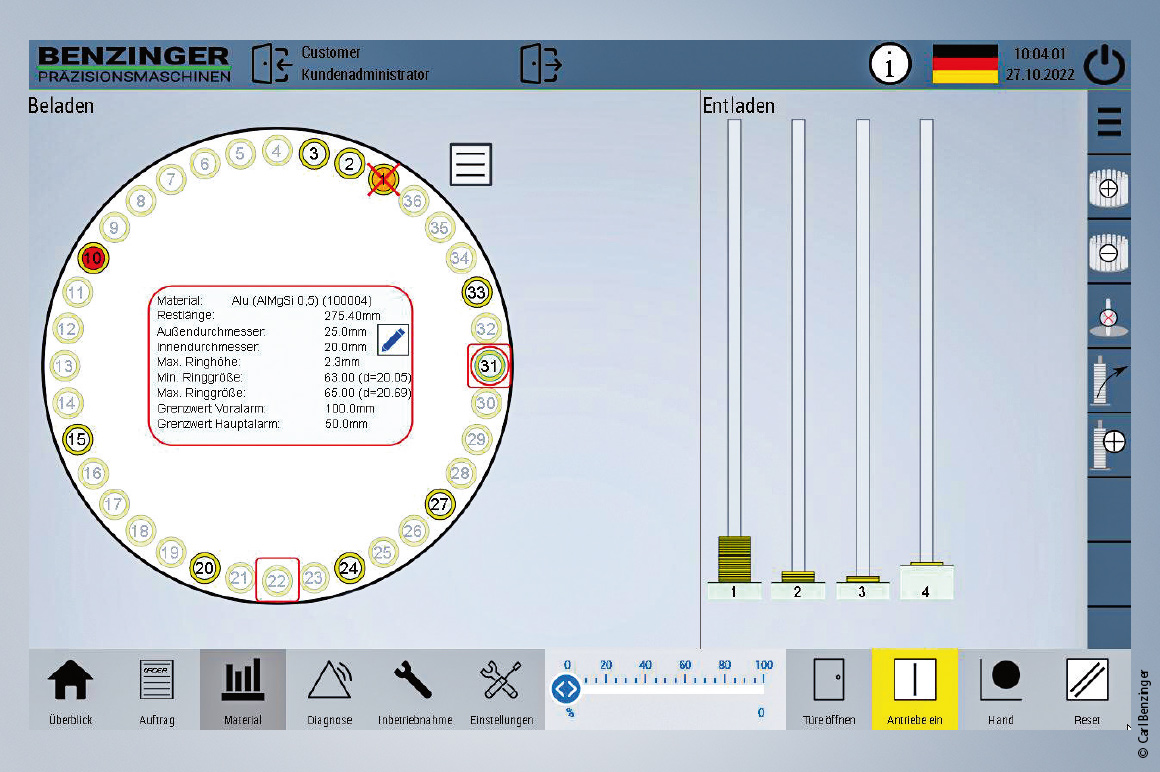

According to Sascha Jentner, there is currently no machine for ring blanks on the market that is comparable to mySaw: Up to 54 tubes made of materials such as platinum, gold, or silver can be stored as raw material in a tube magazine. A tube that is selected to optimally suit the order in terms of material and offcut is taken from the magazine and the ring is then sawn to the required width, widened to the individual ring size or inner ring circumference and passed on to the next processing machine via an unloading bar. In this way, the entire process of blank preparation is automated, significantly reducing the time and costs involved as well as the loss of material – because very thin saw cuts are made and the resulting chips are collected. The comprehensive integration of functions is also confirmed by Christian Spieler, Head of Electrical Design and Software at Carl Benzinger: “Originally, mySaw was designed purely as a sawing machine. The ring widening device was integrated as an addition in order to meet customer requirements as effectively as possible. The implementation of a ring scale as well as AI- and vision-based quality assurance has also made a crucial contribution to the high functionality and efficiency of the system.”

Numerous movements implemented precisely

The numerous precise motion functions within the sawing machine are crucial for an efficient process flow. First, the rotary indexing tube magazine is moved into the correct position based on the raw material selected for the order. A gripper then removes the tube and guides it past a light barrier – to check the gripper position and dimensions – to the sawing unit, which cuts the ring blank to the desired width. After sawing, the blank falls onto an unloading mandrel and the gripper takes the tube back to the magazine and removes the next piece of raw material. At the same time, the sawn-off blank is transported to the removal unit either directly or via the integrated ring widening device.

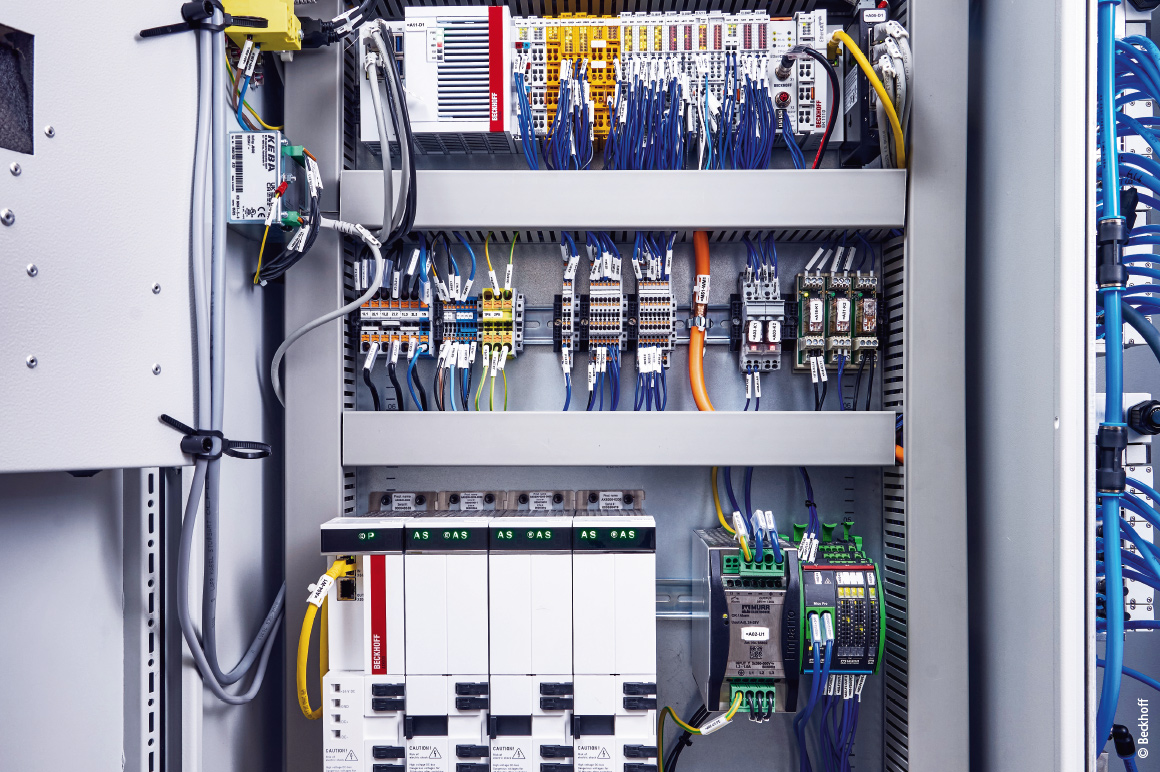

The motion functions for product handling and the sawing unit are implemented via the AX8000 multi-axis servo system and AM8000 servomotors from Beckhoff. In addition, the ring widening device features an AA3033 electric cylinder as a direct drive and an AM8112 servomotor controlled via the EL7211-9014 servomotor EtherCAT Terminal to move a small platform that serves as a ring size target. TwinCAT PLC/NC PTP 10 is used on the software side, installed on the extremely compact CX5240 Embedded PC. Mike Gutekunst, software developer at Carl Benzinger, explains: “All of the engineering is installed on the embedded PC, and very little training and engineering work is required on our part. Another major advantage is TwinCAT’s comprehensive simulation capability, which makes it easy to set up a project step by step. This makes our work much easier, especially since TwinCAT Drive Manager 2 allows us to implement all motion systems – from the compact drive technology to the electric cylinder and AX8000 – in a single tool.”

Christian Spieler cites further advantages of the Beckhoff drive technology: “We chose the AX8000 multi-axis servo system in particular because of its compact design. Added to this are the advantages of the One Cable Technology (OCT), i.e., space and material savings as well as the electronic nameplate. For example, the different tube magazines can be recognized via the nameplate of the respective servomotor and assigned to the appropriate material database.” The project was also made much easier by the EtherCAT industrial Ethernet system with its automatic recognition of all network participants. Furthermore, the openness of EtherCAT makes a wide range of third-party components available and allows them to be easily integrated into the control technology.

PC-based system openness and IT integration

It is not just EtherCAT which simplifies project implementation due to its openness, but also the PC-based control technology from Beckhoff as a whole. Mike Gutekunst adds: “It is an immense advantage that TwinCAT provides an end-to-end platform in engineering as well as in runtime, right through to visualization with TwinCAT HMI. And since the engineering is also installed on the mySaw target system, it is very easy to access the machine worldwide via remote maintenance and carry out diagnostics or troubleshooting if necessary. For us, however, openness also means the modularity and scalability of TwinCAT, which makes it extremely easy to integrate new functions and machine developments such as the ring widening device. The integration into Visual Studio is another bonus for me as a software developer.”

For Christian Spieler, openness is also demonstrated by the ease with which a connection can be established to higher-level IT systems: “This is very important with mySaw, especially with a view to fully automated production. Essentially, there is only a data transmission line to the machine. The end customer orders the ring they want via a configurator and this triggers an order in our customer’s ERP or MES system, which is transmitted to mySaw as a data set. Simple IT integration of PC-based control is therefore crucial. With TwinCAT Connectivity, we are also well equipped for future customer requirements such as communication via OPC UA – the keyword here is simple scalability.”

AI and vision seamlessly integrated into control technology

In conjunction with the ring widening device, the mySaw sawing machine also offers AI quality control for the finished ring blanks. Sascha Jentner explains the importance of this: “With the integrated ring widening device, the number of raw material tubes can be minimized despite the extremely high end product variance. Due to the numerous parameters that influence the widening process, such as material properties and quality, ring width and thickness, and the turning of the ring during the process, it is not possible to predict exactly to what extent the ring can be widened or when the material will give way and break. Without AI or machine learning, the machine is therefore unable to determine whether a ring blank is cracked or not – especially as different defect patterns occur depending on the material and because chips or coolant residues can make it more difficult to detect cracks. In the worst-case scenario, a faulty ring goes through the entire machining process in the downstream machine, which would mean unnecessary time and expense.”

The most important thing when it comes to successful industrial ring production, however, is ensuring that a faulty product does not reach the end customer, which is why a solution for reliable inline quality control had to be found. Mike Gutekunst explains: “The high functionality and integration of Beckhoff control technology meant that we had various options. First, we checked the extent to which the current consumption of the electric cylinder of the ring widening device could be used for inspections. However, with the seamless integration of machine learning and vision in TwinCAT, we ultimately opted for a final optical inspection. An AI model was developed for this purpose and – supported by Nicolas Camargo Torres from TwinCAT Product Management – it was trained with TwinCAT Machine Learning Creator using only around 200 images of good and bad parts, despite the large number of potential sources of error. Overall, this automated training helps us significantly, not least in view of the limited development capacities and the data scientist expertise that would otherwise be required.”

TwinCAT Machine Learning Creator supports the development of the AI model with extensive analysis functionality. According to Mike Gutekunst, this is very important in order to identify whether the reliability of the error detection is sufficient for more intensive training or whether something still needs to be adjusted in the upstream process. The trained AI model then runs directly and in real time in the controller with TwinCAT Vision Neural Network, as easily as any other TwinCAT function and without expert AI knowledge.

Carl Benzinger also benefits from seamless integration, openness, and scalability with respect to machine vision, which runs on a C6025 ultra-compact Industrial PC – together with the AI extension – for a consistently modular machine design. The PC communicates bidirectionally via ADS with the CX5240 as the machine’s main controller through a TwinCAT PLC application for vision and AI and carries out the data transfer and handshake between the two controllers. With TwinCAT Vision, both Beckhoff vision hardware and GigE vision cameras from third-party suppliers can be easily integrated into the control technology. Christian Spieler sees the advantages of the Beckhoff vision solution, with its integrated hardware and software design, as follows: “EtherCAT enables us to integrate the cameras easily and transmit the trigger signals reliably and precisely. The plug-and-play capability, minimized wiring work, and industrial-grade hardware design are all added benefits. In addition, the Beckhoff solution has a very good price/performance ratio overall.”