Linear product transport in a hygienic design

Flexible and fast, even in demanding environments

Headquarters Malaysia

Beckhoff Automation Sdn. Bhd.

+60 3 6151-3088

info@beckhoff.com.my

www.beckhoff.com/ms-my/

Flexible and fast, even in demanding environments

XTS Hygienic is an intelligent transport solution for applications with particularly stringent hygiene and cleanability requirements. This linear transport system can be used in the primary sector of the food and pharmaceutical industries as well as in manufacturing and bottling liquids. It is chemically resistant and easy to clean.

The familiar advantages that the XTS with for building innovative machine concepts are also present in the XTS Hygienic:

The product transport system, which has an IP69K protection rating when assembled and boasts a hygienic design with no concealed edges or undercuts – can easily be cleaned in line with industry standards. Manufactured from 1.4404 (AISI 316L) electropolished stainless steel with a hygienic texture and equipped with high-pressure-cleaner-resistant VMQ silicone seals, the XTS Hygienic complies with EHEDG guidelines. It is chemically resistant to industry-standard cleaning agents, as proven in laboratory tests.

Advantages at a glance:

The overall system is resistant to chemicals and aggressive cleaning agents and can also be cleaned under high pressure. It complies with EHEDG recommendations, and a system with XTS Hygienic can be EL Class I AUX-certified by the user.

The XTS Hygienic is technically very similar to the standard XTS and offers all the essential advantages of the XTS system in addition to hygiene benefits:

XTS Hygienic combines high efficiency and precision with hygiene standards and flexibility.

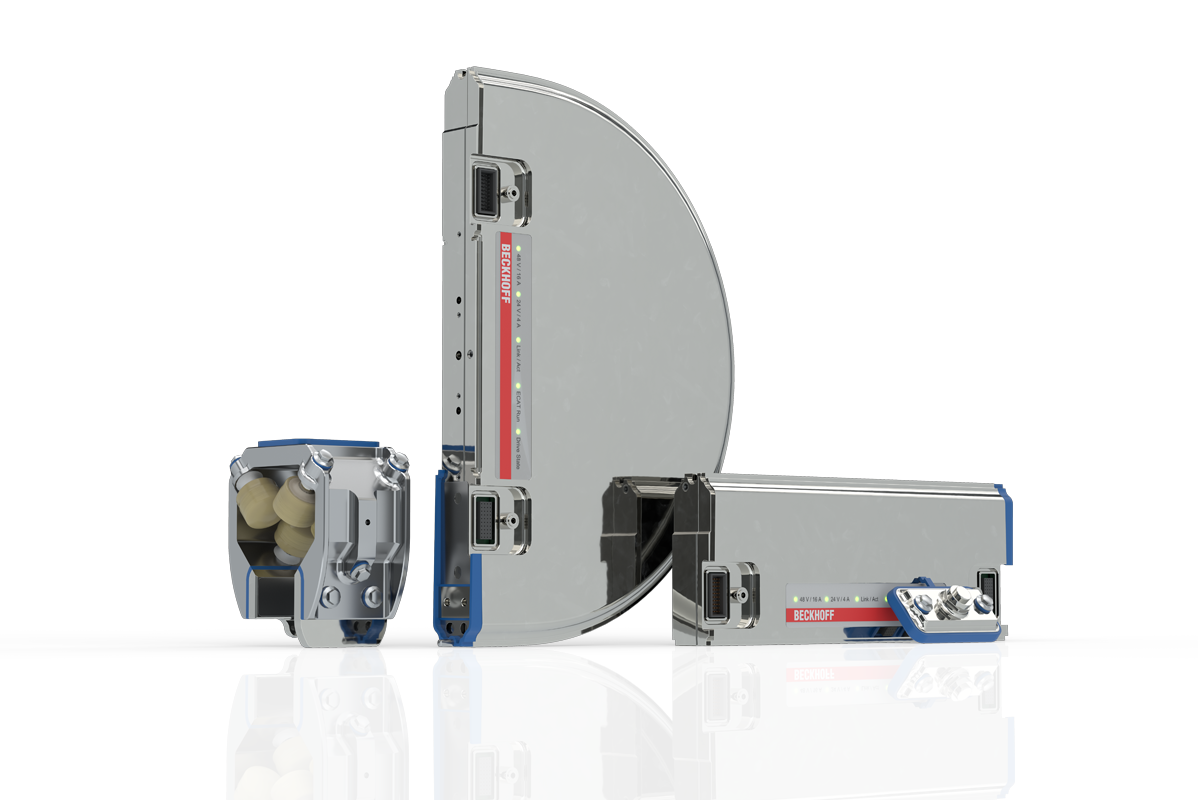

The XTS Hygienic motor modules are designed from the ground up for use in demanding environmental conditions.

A stainless steel housing shell protects the electronics. Lateral plug contacts for power and communication transmission make it particularly easy to connect the modules. A cover, which contains the necessary connection contacts, connects two motor modules together securely and can also serve as a power supply point. This enables flexible adjustment of the power supply points without needing to dismount the motor modules.

The XTS Hygienic motor modules are made of stainless steel and have no concealed corners, edges, or recesses, which makes them easy to clean. Hygienic seals between the modules and at all screw connection points protect against penetration by liquids. All supply lines for power and data are routed in a sealed protective tube, and its surface prevents microbes from accumulating.

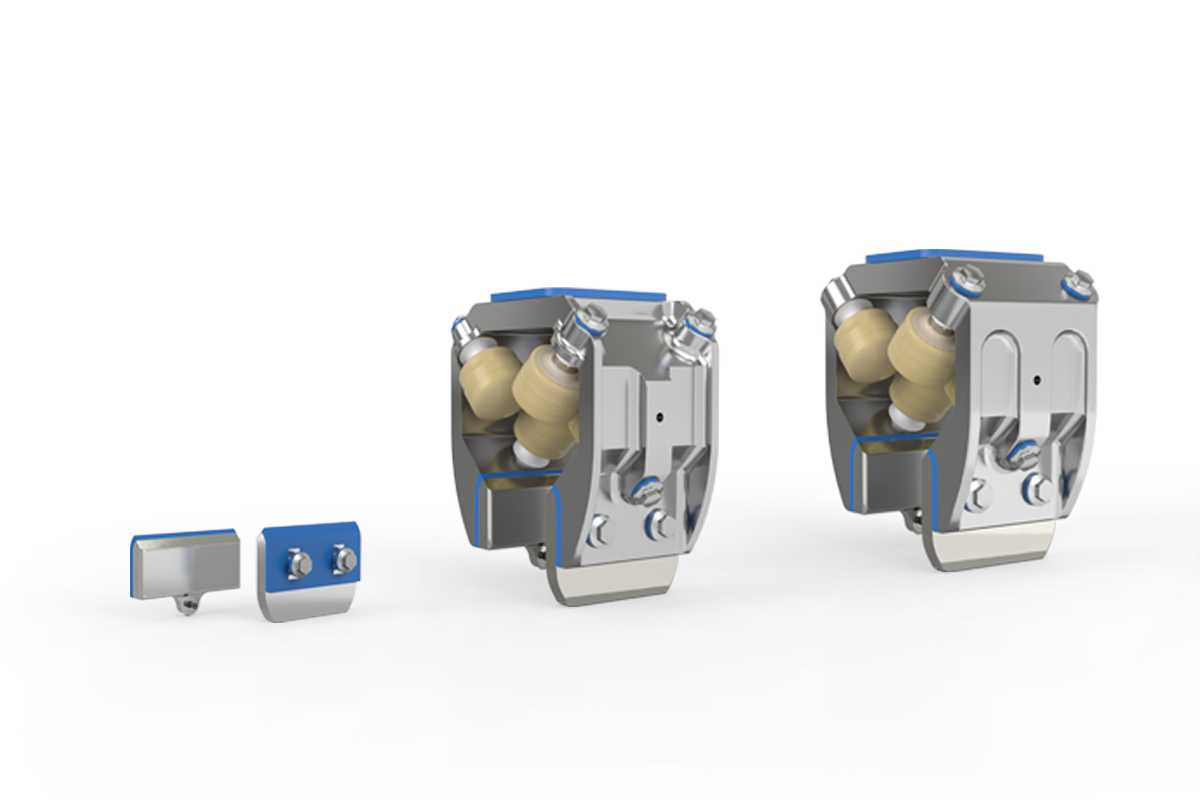

The individually controllable movers also play a central role in the XTS Hygienic. They are made of stainless steel or aluminum and are particularly resistant.

Their shape makes them easy to clean, which means that they meet strict hygiene requirements even in environments that are particularly sensitive to contamination.

The magnetic plate set in a hygienic design is available as a single item for movers from other manufacturers.

XTS Hygienic reduces glass-to-glass contact and meets pharmaceutical industry standards

HOF Sonderanlagenbau, based in Hesse in Germany, provides freeze-drying systems, loading and unloading systems, freezing and thawing equipment, and special solutions for the pharmaceutical industry. The XTS Hygienic is used in HOF Sonderanlagenbau’s new plant concept for transporting pharmaceutical products.

The stainless steel version of the XTS intelligent transport system meets all industry standards. It is designed for use in an isolator and can be cleaned with hydrogen peroxide. XTS also enables particularly gentle product transport, which has reduced glass-to-glass contact.

The motor modules with the product designation ATH200x are elements for the construction of straight XTS track sections for demanding environmental conditions. Via lateral plug-in contacts for the transmission of power and communication, a connection between the motor modules can be established very simply with the help of a cover. The cover contains the necessary contacts for the connection of two motor modules and is optionally also available with a supply cable in order to serve as a power supply point. The subsequent relocation of the power supply points or a change in the number of power supplies is possible without dismounting the motor modules.

The motor modules with the product designation ATH205x are elements for the construction of curved XTS track sections for demanding environmental conditions. They represent a 180° curve segment (outside curve) with a clothoid-shaped geometry. Via lateral plug-in contacts for the transmission of power and communication, a connection between the motor modules can be established very simply with the help of a cover. The cover contains the necessary contacts for the connection of two motor modules and is optionally also available with a supply cable in order to serve as a power supply point. The subsequent relocation of the power supply points or a change in the number of power supplies is possible without dismounting the motor modules.

The XTS Hygienic movers are optimally matched to the motor modules and guide rails. They are available in two different types of material: a stainless steel mover for particularly hygienically demanding environmental conditions and a mover made of anodized aluminum, which can transport larger payloads with higher dynamics than the stainless steel variant. The design and the materials of the movers allow cleaning in a washing machine. The feedback flag is an integrated component of the completely encapsulated magnetic plate set of the mover. Customer-specific attachments and tools can be mounted on the mover using a seal that is included in the delivery contents to ensure that the same hygienic requirements can also be met with customer connections.

The magnetic plate sets with the product designation AT9001 are part of the AT90xx mover. When using guide rails with movers from third-party suppliers or with self-designed movers, the magnetic plate set is available individually. The magnetic traveling fields of the XTS motor modules generate a linear movement with the aid of the magnetic plate sets. A set consists of two magnetic plates. One of the two magnetic plates is equipped with a sturdy encoder flag, which allows non-contact position detection of the movers.