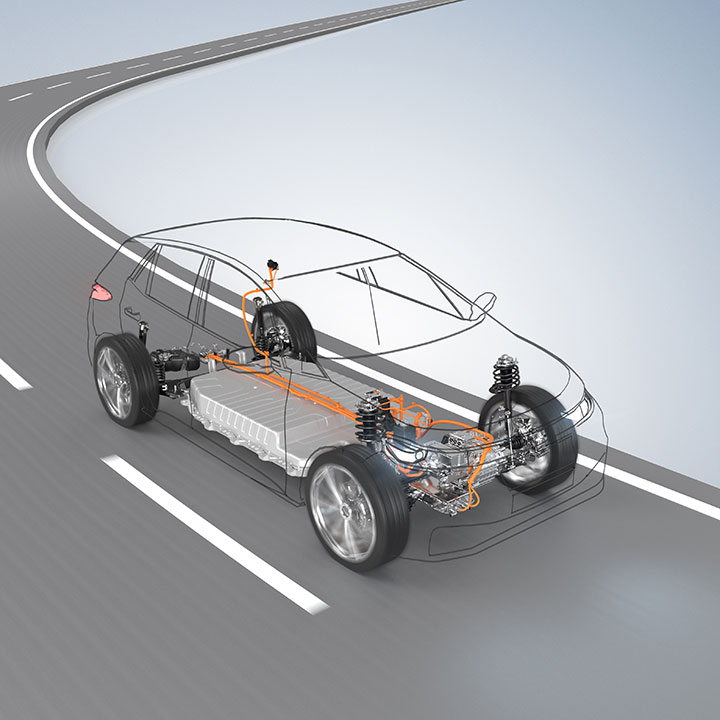

The automotive industry is undergoing a revolutionary transformation process. The switch to electromobility, autonomous driving, and global market shifts require huge investments. Managing these challenges while remaining competitive means cutting costs and becoming more efficient. The production process – and body construction in particular – is a potential area where this could be achieved. Although automation and robotics have long been a feature of the body in white process, there are still key challenges presented by cost pressure, a shortage of skilled workers, and flexibility. How can you master these better than ever and take your production line to a new level of automation? With solutions from Beckhoff that make body construction even smarter, control cabinet-free, and compressed air-free. They reduce your workload, increase flexibility, and save hardware and resources.

How Beckhoff brings advantages for body construction

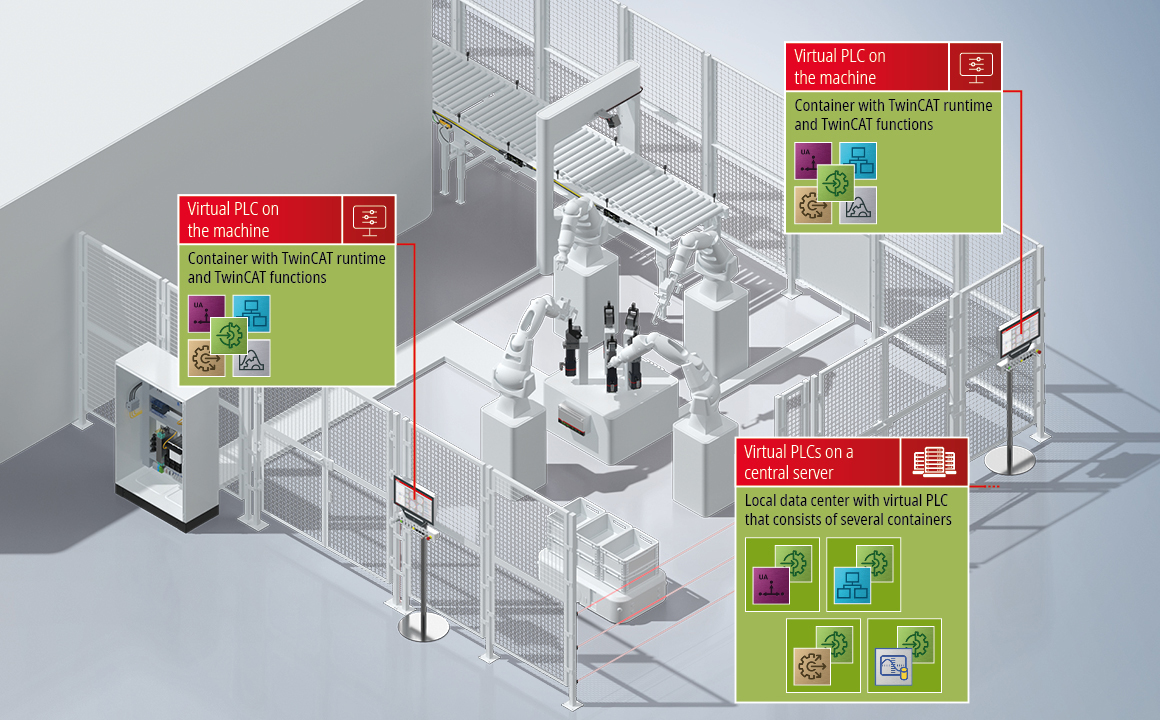

- smart – with virtual PLCs (VPLCs) for intelligent networking of IT and OT

- control cabinet-free – thanks to distributed automation with the new MX-System

- compressed air-free – thanks to compact drives for electric power clamps, for example

- cost-cutting – due to savings on hardware, wiring, and installation and maintenance costs

Boosting efficiency in body construction with automation from Beckhoff

MX-System reduces costs and complexity

As the level of automation in body construction increases, machine and system control cabinets are becoming a bigger presence. Complexity and cabling work are growing while flexibility and scalability are dwindling. What’s more, installation and maintenance require expensive specialists and an increasing amount of space in production. At least, that’s how it has been until now. Now, Beckhoff’s new MX-System is paving the way for technical progress based on control cabinet-free automation. The system consists of a baseplate and a kit of function modules. The baseplate is installed directly in the machine and has standardized slots to accommodate the function modules, which are simply attached and screwed on as required. That's it – then you're ready to go!

How you benefit from the MX-System

- control cabinet-free distributed automation of machines and systems – working in combination with decentralized drive technology from Beckhoff

- saves space and hardware: no control cabinet, fewer components

- simple plug & play installation without manual cabling work

- conserves valuable resources and reduces the machine footprint

Next-level automation with the VPLC from Beckhoff

In body construction, the automation software usually runs on controllers in the field. The control system and machine are close together, thus ensuring real-time communication, but this involves a great deal of outlay. If software settings need to be adjusted or upgrades installed, for example, this can only be done directly and physically on the devices. Control solutions with virtual programmable logic controllers – or VPLCs for short – are one solution to this issue. With TwinCAT for Linux®, Beckhoff is harnessing its strength by modularizing runtimes and functions in the form of containers. This allows applications to be distributed across multiple containers and makes it possible to implement VPLC architecture control technology both on central servers and in a distributed manner.

How you benefit from VPLCs from Beckhoff

- increased flexibility: virtual control systems can be easily scaled and adapted

- lower costs: VPLCs significantly reduce the need for physical hardware in the field

- simplified maintenance: no need to work on physical hardware changes to settings and software updates are quick and easy

Distributed drive technology for electric power clamps

Compressed air-driven processes and tools are a standard component of body construction. These systems consume a lot of energy and space, and are also high-maintenance, one example being the large number of pneumatic power clamps used for clamping, positioning, and holding sheet metal. Electric power clamps equipped with decentralized drive technology from Beckhoff provide an alternative. These use the AMP8000 and AMI8100 servo drive systems and the ASI8100 stepper motor drive. Users benefit twice over, as Beckhoff’s compact drive systems have integrated control intelligence and are a powerful replacement for pneumatics, allowing for control cabinet-free conversions with short cable runs that take up minimal space.

How you benefit from distributed drive technology from Beckhoff

- less effort and costs for wiring, installation, and operation

- reduced machine footprint thanks to shorter cable runs and lower space requirements

- full compatibility with EtherCAT and Beckhoff TwinCAT

- with TwinSAFE for integrated safety functions (STO/SS1)

More information

Automotive industry

PC-based control from Beckhoff supports modern manufacturing concepts for the mobility of the future.

Sheet metal working

High performance built-in: PC-based control from Beckhoff for all control and drive applications in sheet metal working

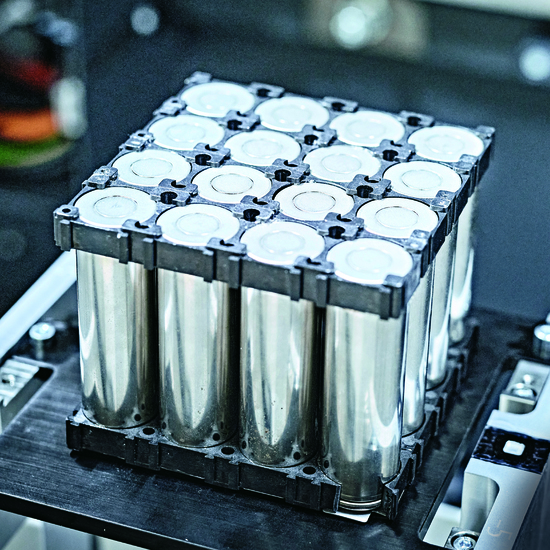

Battery production

High-performance automation technology for all stages of battery production.

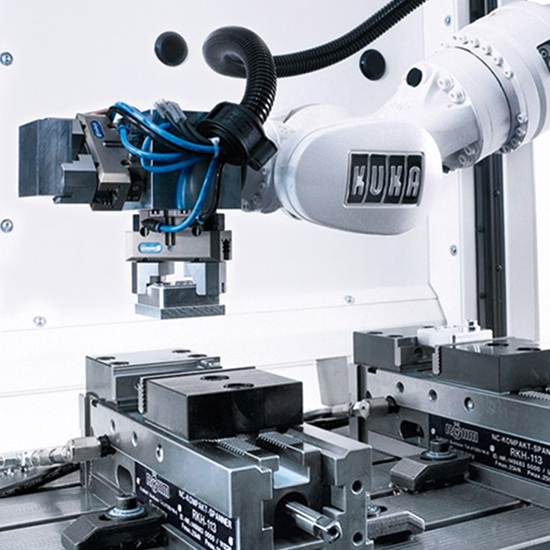

Assembly and handling technology

PC-based control technology from Beckhoff optimizes the entire process chain: from handling, production, and assembly to testing, control, and management.