There’s a stage for every story at PAC NYC using flexible automation

The Perelman Performing Arts Center in New York (PAC NYC) offers visitors a truly unique theater experience. Advanced stage technology makes its three performance spaces extremely versatile. Modular automation technology from Beckhoff provides the necessary flexibility and reliability for converting walls, floors and backdrops according to the performance schedule.

At the foot of Manhattan’s One World Trade Center building and across from the 9/11 Memorial & Museum stands the PAC NYC. While it offers programming similar to other major New York City theaters, the mission of this gathering space is distinctly communal. “PAC NYC is a place of civic healing,” says Miranda Palumbo, Director of Digital Content at PAC NYC. “Because we are on the World Trade Center campus, it's our responsibility to help everyone celebrate life.”

The venue features three performance spaces that can flexibly combine or divide into over 60 configurations. The backstage technology also supports dynamic set changes and flying performers through the air. “We could produce three different pieces of work at the same time or just one,” Palumbo explains.

To harness the necessary engineering behind the performance art, PAC NYC directed The Chicago Flyhouse, Inc. and its programming partner, ELPLANT, to implement a safe, reliable, and flexible stage automation system. Flyhouse provides rigging, hoisting, and performer flying equipment for venues across the world ranging from hospitals and high schools to theaters and arenas.

Advanced stage technology needed for unique project

“The Perelman was a unique and exciting project,” says Mark Witteveen, Founder and Senior Project Manager at Flyhouse. “You rarely build new theaters in New York City, especially in Manhattan’s Financial District. Plus, the design team and consultants wanted to develop a very flexible space.”

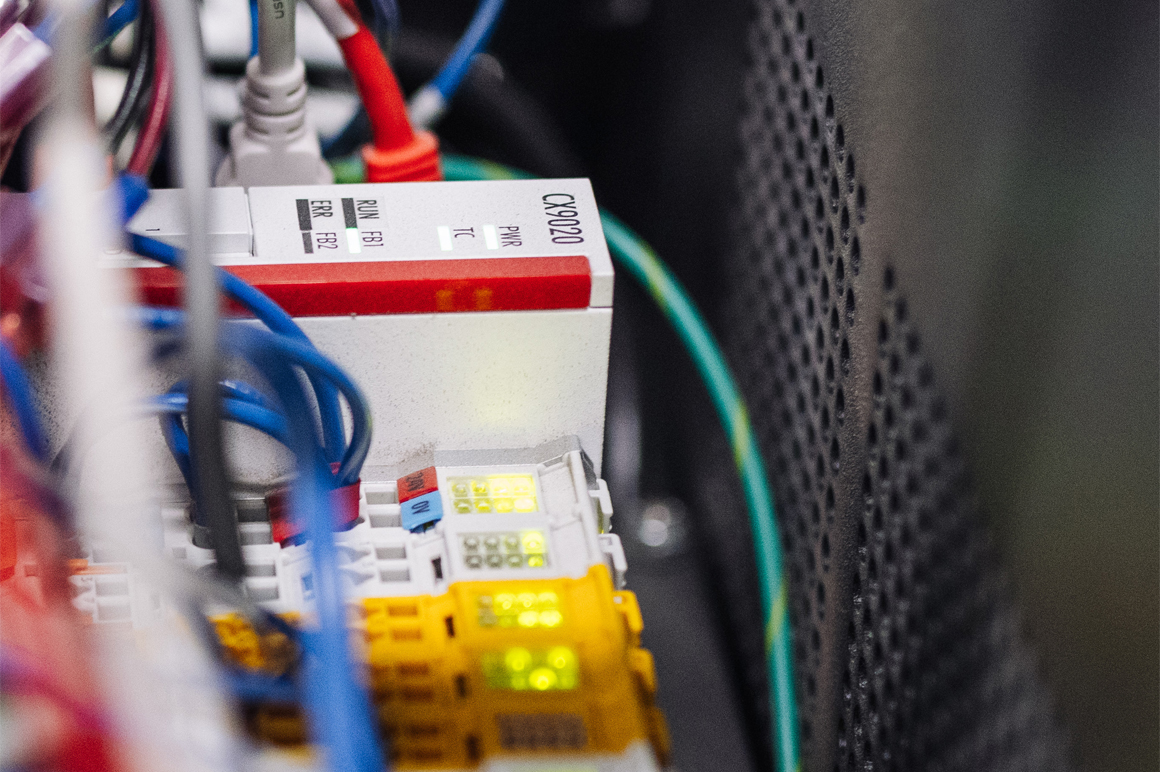

Therefore, Flyhouse used its distributed “MoM-and-Kid” control concept. A central server (Master of Machines, MoM) communicates to distributed modules (the Kids). The more than 30 Kid modules at PAC NYC each have their own Beckhoff CX9020 Embedded PC and EtherCAT I/O wired to control Flyhouse’s ZipLift hoists and other equipment. The modules can be easily moved, connected to other hoists, or swapped for maintenance.

Still, the large number of Kid modules and their associated motion axes throughout the theater level raised the bar on the facility’s networking capabilities. The Flyhouse technologies also needed to interface with other vendors’ solutions, for example, the systems to raise and lower the massive walls or change the floor configuration to be flat or stairstep up. So, safety zones had to adjust dynamically as spaces changed to ensure human and equipment safety.

“You can lose 10 years of reputation with one component that's acting erratically, so it’s vital to partner with the right companies,” Witteveen says. “Even though the duty cycles are relatively short in theaters, we need the reliability that comes with industrial automation.”

Here, Beckhoff supplied an ideal solution. The EtherCAT and PC-based control technology provides a foundation for seamless operation and high adaptability.

Industrial automation – combining safety with flexibility

Flyhouse collaborated with Beckhoff USA and ELPLANT to design next-generation control modules. ELPLANT , an ISO 9001-certified systems integrator based in Serbia, brought expertise in industrial automation and entertainment applications.

“For this project, Beckhoff was undoubtedly the logical choice, as few systems could provide such a modular and configurable architecture,” says Aleksandar Arsić, CEO of ELPLANT.

“For this system, we used TwinCAT PLC, NC PTP motion control, TwinSAFE safety systems, extensive EtherCAT communication, TwinCAT PLC visualizations, TwinCAT HMI, database communication, and ADS with third-party applications, such as C# WPF (Windows Presentation Foundation) operator consoles and similar solutions.”

Another key enabler of the modular design was the EtherCAT industrial Ethernet System, explains Aleksandar Arsić: “This real-time communication allowed us to configure the topology so that each embedded PC or other EtherCAT device operated as an independent sync unit.” Much of the equipment also features EtherCAT P, which combines data and power on one cable. This configuration allows techs to remove or add kid modules without taking all the others offline. Beyond sheer speed and robust diagnostics, the EtherCAT supports free selection of topology. It also offers hot connect functionality and automatic addressing of devices, simplifying component exchange and plug-and-play installation.

Flyhouse also harnessed integrated functional safety with TwinSAFE terminals. Here, safety information is transmitted via Safety over EtherCAT (FSoE) over the standard EtherCAT network, rather than a separate, hardwired system. Beyond the reduction in wiring effort and cost, TwinSAFE simplified implementation of the configurable theater concept.

Flyhouse deployed its Ease® Control Console in each theater space, simplifying axis operation with joysticks and a multi-touch screen with a visualization built with TwinCAT HMI. The consoles can’t access axes outside the operator’s line of sight for safety reasons, according to Mark Witteveen. So, when raising walls to combine spaces, the consoles now need to control all the axes in that larger room. Likewise, E-stop buttons need to halt all motion in combined spaces if required, meaning that the mom-and-kid architecture must change on the fly. “This seemingly simple idea proved incredibly complex to implement,” Witteveen says. “But with the flexibility of EtherCAT and software capabilities in TwinCAT, we pulled it off seamlessly.”

Magical language of art and engineering combined

Every aspect of PAC NYC was intentional. The building’s foundation was acoustically isolated to ensure subway trains and other underground activity wouldn’t affect performances. The unique outer walls are made of thinly sliced slabs of marble and glass, letting sunlight in during the day and making the theater glow as a New York City beacon in the evening. The lobby level features a restaurant run by a celebrity chef and a stage where musical acts and other artists give free performances most days of the week.

The stage automation needed to be equally intentional. The modular system will continue to support upgrades, and with a scalable, future-proof automation platform, this process won’t require a rip-and-replace of infrastructure. Instead, technicians can simply make changes in software or replace a device with a newer version. Beyond reducing costs, this approach avoids unwanted intermissions to find obsolete components. To Mark Witteveen, ensuring that the show will go on remains the most important goal. “When the lights dim and the stage comes to life, the audience isn’t thinking about automation,” he says. “They’re simply immersed in the magic. That experience makes all the effort worthwhile.”