PC-based control for body construction

A giant leap for efficiency with intelligent automation

PC-based control for body construction

A giant leap for efficiency with intelligent automation

Hovedkontor Danmark

Beckhoff Automation ApS

A giant leap for efficiency with intelligent automation

A giant leap for efficiency with intelligent automation

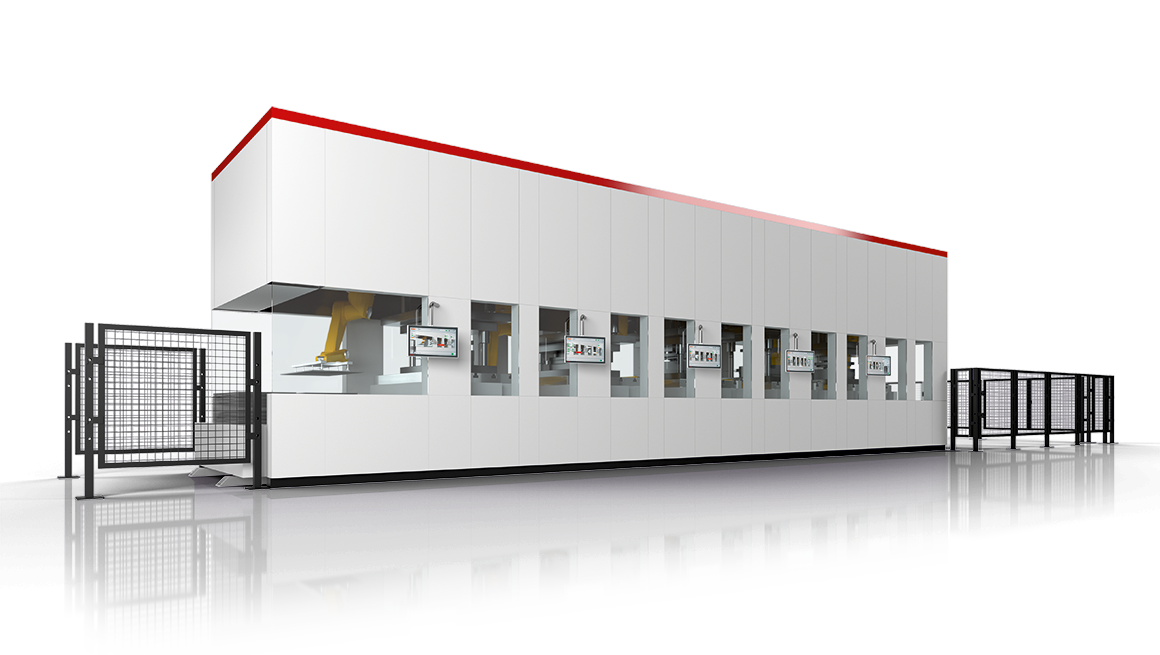

The pressure to optimize sheet metal working is increasing: fluctuating demand, small batch sizes, the shortage of skilled workers, and ever shorter product life cycles require production solutions that offer a high level of flexibility and economic efficiency. Whether for pressing, cutting, welding, punching, nibbling, or bending – machines that adapt to new requirements quickly and offer maximum efficiency and quality are in demand. You can achieve both with automation and control solutions from Beckhoff. Our fully PC-based platform combines openness, performance, and modularity to create a system that makes your machines and systems fit for the future.

Do you have any questions?

Whether a hydraulic deep drawing press or servo-electric transfer press – Beckhoff’s modular and scalable control technology enables you to automate all press types. Powerful industrial PCs in combination with our EtherCAT fieldbus technology ensure high-performance and highly dynamic processes. Our solutions capture signals in real time and transmit control commands immediately. With fully automated transfer presses or complete press lines, this pays off in terms of a clear increase in productivity.

There are also other advantages: For example, specially optimized gear couplings and pre-controlled pressure regulators are available for the deep drawing process. Combined with PC-based control technology and cycle times of less than 250 µs, short synchronization paths are achieved – even at very high speeds of the upper tool. Our portfolio also covers all control requirements: with I/O systems for all common fieldbuses, TwinCAT automation software for PLC and motion control, a comprehensive range of drive technology components, and the integrated TwinSAFE safety solution.

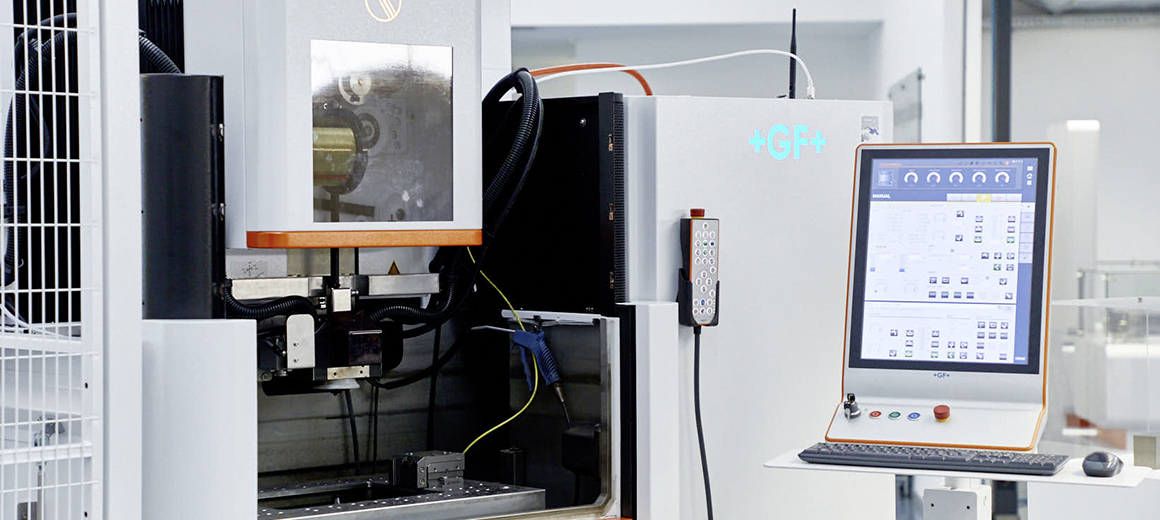

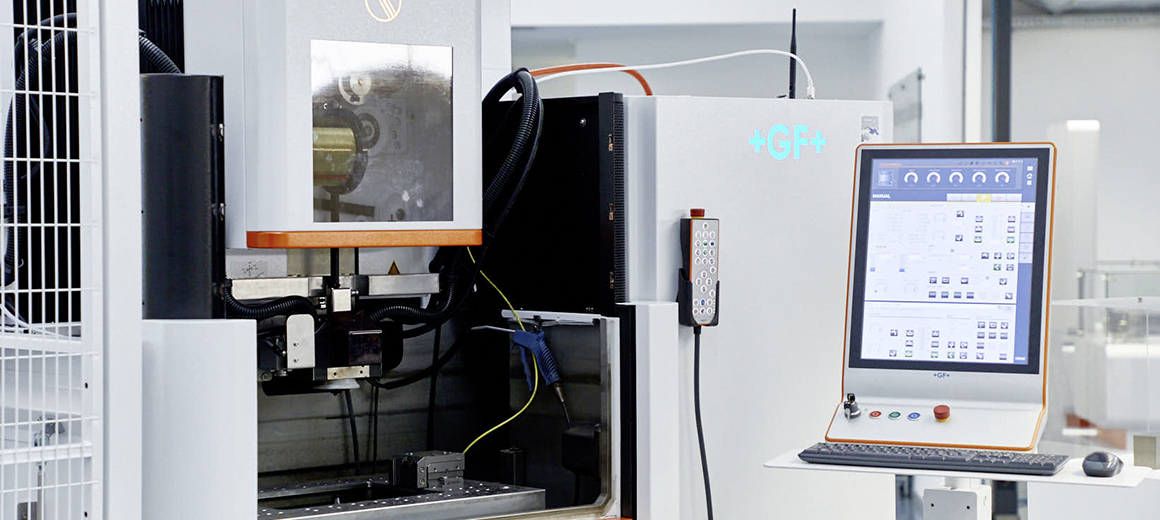

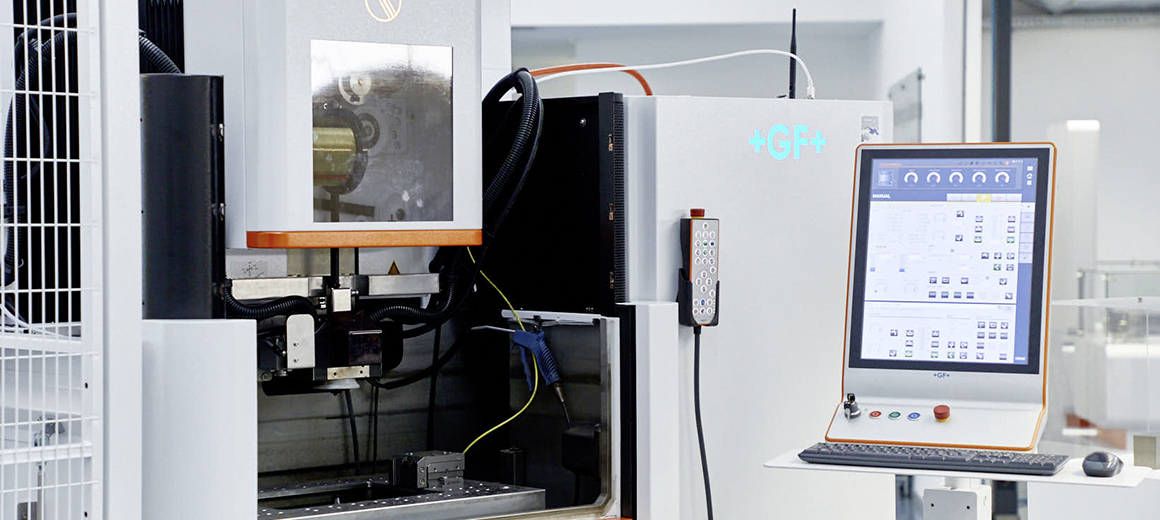

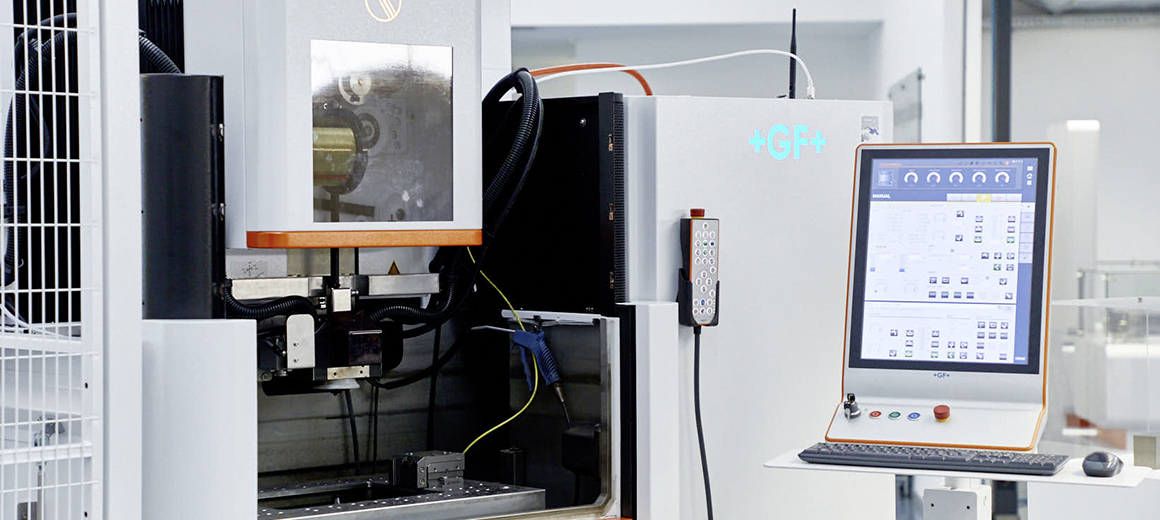

CNC controllers from Beckhoff are world leaders when it comes to the highly precise cutting and welding of sheet metal – whether in oxy-fuel, plasma, laser, or water jet processing. Two factors are decisive for this competitive strength: the control speed and the scope of the CNC functions. Our technology is impressive in both disciplines. Firstly, EtherCAT ensures high-performance control with cycle times of less than one millisecond. This means that even the fastest cutting and welding processes can be precisely controlled. Secondly, TwinCAT is an integrated component of our control platform that covers the entire range of functions for your CNC requirements with the TwinCAT NC I and TwinCAT CNC software libraries.

Our controller is complemented by a well thought-out product portfolio. It includes compact C60xx series Industrial PCs, which have powerful processors to meet the complex requirements of sheet metal working. All components are designed to be compact. This reduces the space required in the control cabinet; in many cases, the MX-System can replace the cabinet altogether – for an even leaner machine design and the sheet metal working of the future.

PC-based control technology from Beckhoff is perfect for the challenges of punching and nibbling. Highly dynamic axis movements can be realized just as easily as fast control functions. Precisely programmable strokes, automatic tool changes, and the ability to change programs or machine settings even during operation ensure consistently high levels of productivity. Key to this are TwinCAT motion control and the TwinCAT NC I and CNC software libraries.

TwinCAT controls the movements of all servo axes and automatically adjusts the processing parameters to the sheet thickness. Thanks to precisely programmable strokes, even special shapes can be quickly punched into the sheet metal. The combination of powerful industrial PCs and EtherCAT communication enables stroke rates of over 2,000 strokes per minute. Go one step further with our eXtreme Fast Control Technology (XFC). This shortens the cycle times for data transfer to less than 100 µs. The advantage? Information from press force monitoring or tool fastening is recorded almost simultaneously by all sensors and sent to the central controller.

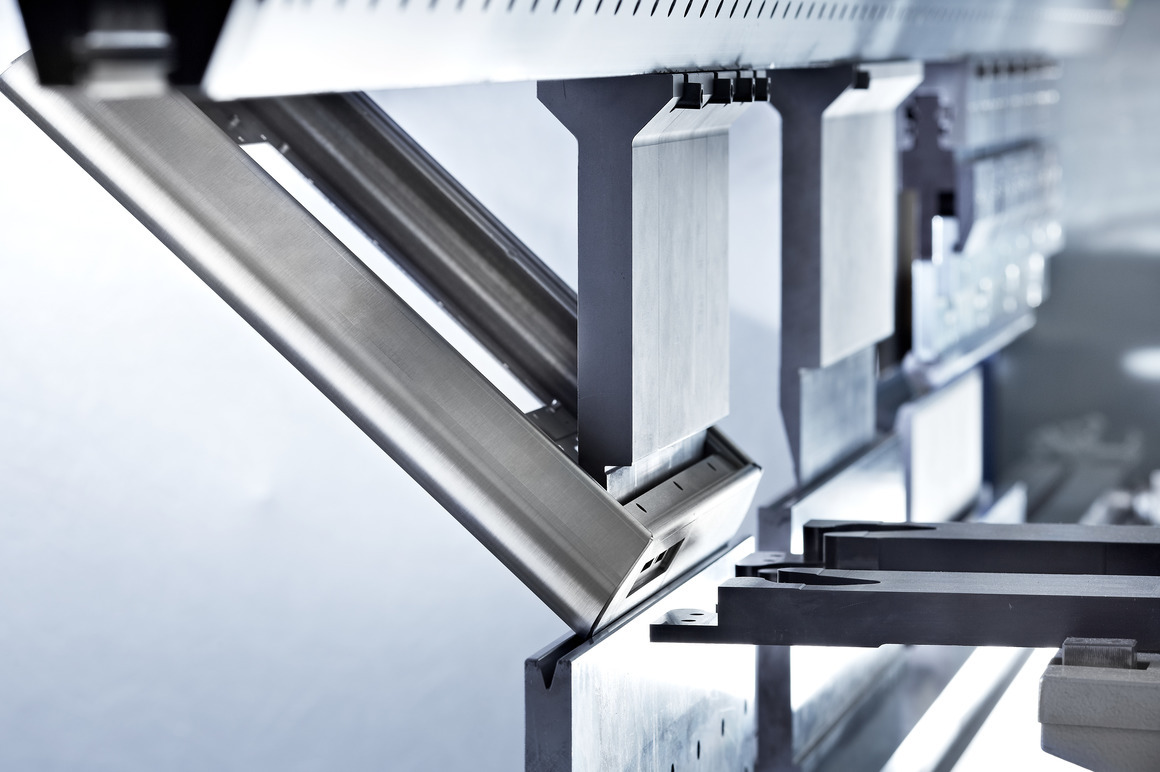

The challenges of folding and bending sheet metal are as varied as your machines and systems. Whether round, pipe, swivel, or die bending machines – our PC-based and open control technology provides you with all the system modules you need for automation. The various function modules can be used in combination or individually. For bending, for example, we provide you with a choice of tailored technology solutions for the press beam or back gauges.

We also offer you ready-made algorithms for calculating the insertion depth and for the exact positioning of the back gauges. Collisions during the folding process are reliably avoided due to the automatic calculation of the bending order. TwinCAT automation software has open interfaces so that you can easily implement individual adaptations and extensions and add your own algorithms at any time. In addition, the entire range of Beckhoff EtherCAT I/O modules and our scalable industrial PCs are available to you. Additional functions such as suitable safety technology or solutions for energy acquisition and condition monitoring round off the portfolio.

The Beckhoff CNC solution enables highly dynamic axis movements in punching and nibbling.

PC-based control from Beckhoff provides the ideal platform to automate folding and bending processes.

Moser-Baer AG in Switzerland is streamlining the production process for its world-famous railroad clocks with a new type of profile bending machine: With four bending rollers instead of the usual three, the Mobamatic MPB23 profile bending machine, with the mechanical platform developed and built by Moser-Baer, can bend a wide variety of profiles without straight end pieces. The automation specialist Pneutronic AG implemented the complete drive and control technology. PC-based control and the AX8000 multi-axis servo system with TwinSAFE ensure a compact design, precision, and safe operation without safety guards and laser scanners.

In this Beckhoff Trade Show TV from EuroBLECH 2024, we will show where PC-based control from Beckhoff is used in sheet metal working, in particular on the machine from Baykal Machinery. We also show, how the MX-System can reduce the footprint of machines and systems.

Laser ISSE, a Turkish company, relies on Beckhoff for its custom laser machines. Mustafa Özdemir, control system engineer at Laser ISSE, tells us which industries the machines are used in and which Beckhoff products are installed in them in this video.

Cincinnati Incorporated (CI) has been building sheet metal processing equipment for 125 years and continues to support its durable machines for decades. The company is able to do this because it develops everything in-house, from the hardware to the software. However, the further development of proprietary control technology became too costly and challenging to support. Since the switch to PC-based control, the only limits to development have been physical, according to the engineers at CI.

Clifford Machines & Technology develops and markets industrial welding, grating, and wire working equipment. We asked Lance Deysel, Managing Director, which Beckhoff products they use in their machinery and why they opted for them.

In die casting, vacuum generation in the shot chamber and mold cavity helps to avoid air and gas inclusions in the castings, as these would impair the stability of the finished parts. For this purpose, AJYa Vacuum Technology from China developed a complex but particularly effective multi-stage solution. A suitable control platform was implemented in cooperation with the automation partner Beckhoff.