Selection of the drives and motors, particularly the dimensioning of drives and motors, in conjunction with the optimum selection of motor, gear unit, drive controllers, and accessories, is the foundation for efficient machine design. The TwinCAT 3 Motion Designer tool can be integrated in the TwinCAT automation platform or used as a stand-alone project engineering tool for drive and motor selection.

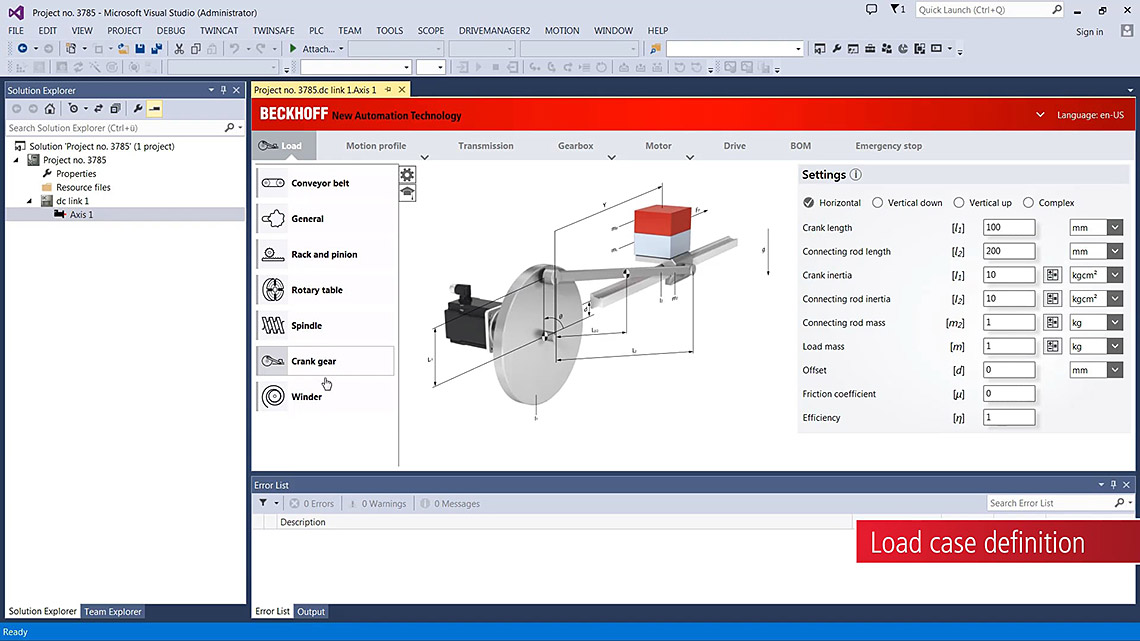

Mechanics

The TwinCAT 3 Motion Designer supports the designer in selecting typical mechanics, such as rack and pinion, ball nut, winder, crank drives, etc.

Motion profiles

Rough calculations of simple load cases with motion profiles, e.g. according to a ½ or ⅓ rule or according to a 7-segment profile, can be executed easily with just a few clicks. Multidimensional tasks and kinematic systems, perhaps in conjunction with more complex motion profiles, including cam gears in accordance with VDI 2143, are also taken into account in the TwinCAT 3 Motion Designer. Export functions enable the configuration to be transferred directly to the TwinCAT System Manager, without repeated inputs.

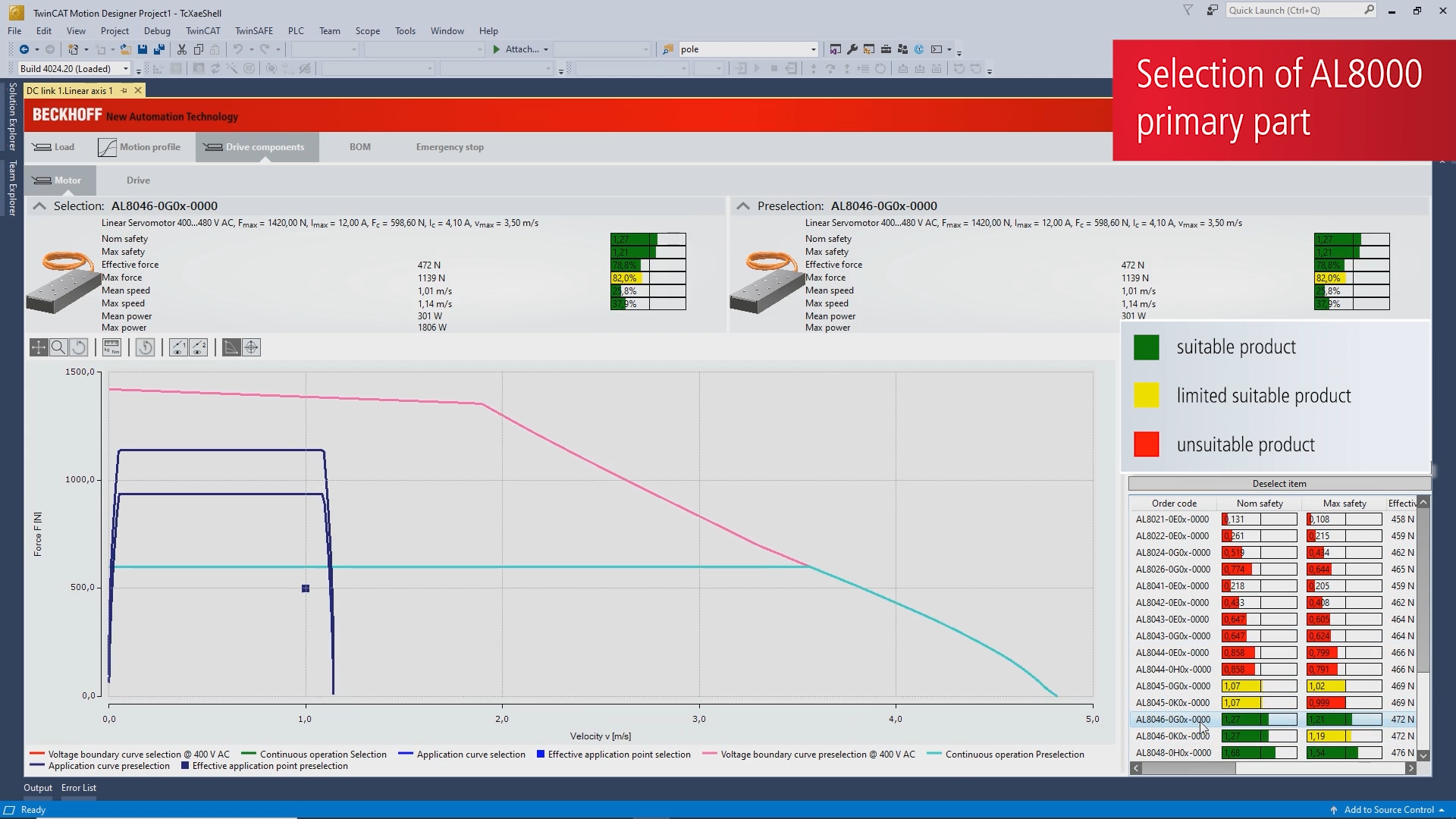

Optimization function

An optimization algorithm makes selecting gear units and motors straightforward. It suggests the optimum combination based on mechanical and cost considerations while taking adjustable filters into account. The connected database provides access to all available gear units, motors, and servo drives offered by Beckhoff, including the compact drive technology range with servo terminals. The automatic geometry matching feature checks the compatibility of the motor and gear unit and prevents unsuitable combinations from being selected.

Report functions

The axis dimensioning is documented in a report. Short or detailed reports are available.

With a single click, the designer can call up the technical data sheet for the motor and gear unit, and the corresponding 3D model of the drive components for integration in the design software with another click.

Parts list generator

The integrated parts list generator can be used for preparing the purchase order right away. Accessories such as cables, chokes, and installation material are also taken into account.

Multi-axis dimensioning

The TwinCAT 3 Motion Designer considers the machine as a whole with all drive axes: all load cycles are taken into account with their temporal dependency and their influence on the common DC link. Selection of the optimum supply module or the common braking resistor is guaranteed.

Product status:

regular delivery

© Beckhoff Automation 2025 - Terms of Use