Modular control platform facilitates innovation in the hydrogen industry

With a seamless modular control solution from Beckhoff featuring over 500 data points and numerous ELX series terminals with intrinsically safe interfaces, Greenlight Innovation is breaking new ground in hydrogen testing. This advanced setup allows for precise and safe monitoring and management of complex hydrogen processes, enhancing both reliability and efficiency in testing operations.

As the world increasingly looks to hydrogen as a clean energy solution, the companies developing these technologies face a critical challenge: safely and accurately testing their innovations before they reach the market. Greenlight Innovation, headquartered in Burnaby, British Columbia, has emerged as a global leader meeting this need, as the company says.

In 1992, Greenlight was founded as a supplier to the fuel cell industry. “Since then, electrolysis has become a major focus,” says Greig Walsh, Chief Commercial Officer at Greenlight. “As the hydrogen industry evolved, we saw increased demand for equipment to test hydrogen production technologies.”

Reliable control platform for complex test processes

Among Greenlight’s product portfolio are test stations for industrial-scale electrolyzers – systems that split water into hydrogen and oxygen using electricity. Their largest systems, capable of testing 4 MW electrolyzer stacks, represent their most complex engineering challenge. “The equipment is very complicated and technologically demanding,” says Christian Bosio, Managing Director at Greenlight. “That machine has thousands of components that we're putting together, and it has to work as one. Everything has to be top-notch, very high quality, and reliable.”

These test stations must control high-pressure gases up to 50 bar, regulate temperature across multiple zones, and manage potentially explosive hydrogen-oxygen mixtures – all while ensuring continuous operation with minimal operator intervention. Under these conditions, safety presented the most demanding challenges. “Electrolyzer test equipment operates at higher pressures, so the safety requirements are significant,” Christian Bosio says. “As we get into these megawatt-class systems, the safety requirements have been compounded, making safety a critical factor in all of our designs.”

Greenlight's systems needed to support different safety protocols depending on deployment location while maintaining the same high performance standards as well as meeting customer-specific requirements.

Standardizing on flexible automation from Beckhoff

Before finding the right control platform, Greenlight overcame a number of specific challenges, including struggling with bulky I/O modules and communication reliability issues with their previous systems. "We were very conscious that this equipment needs sophisticated electronics and control systems, so we wanted to make an educated choice at the beginning," explains Greig Walsh.

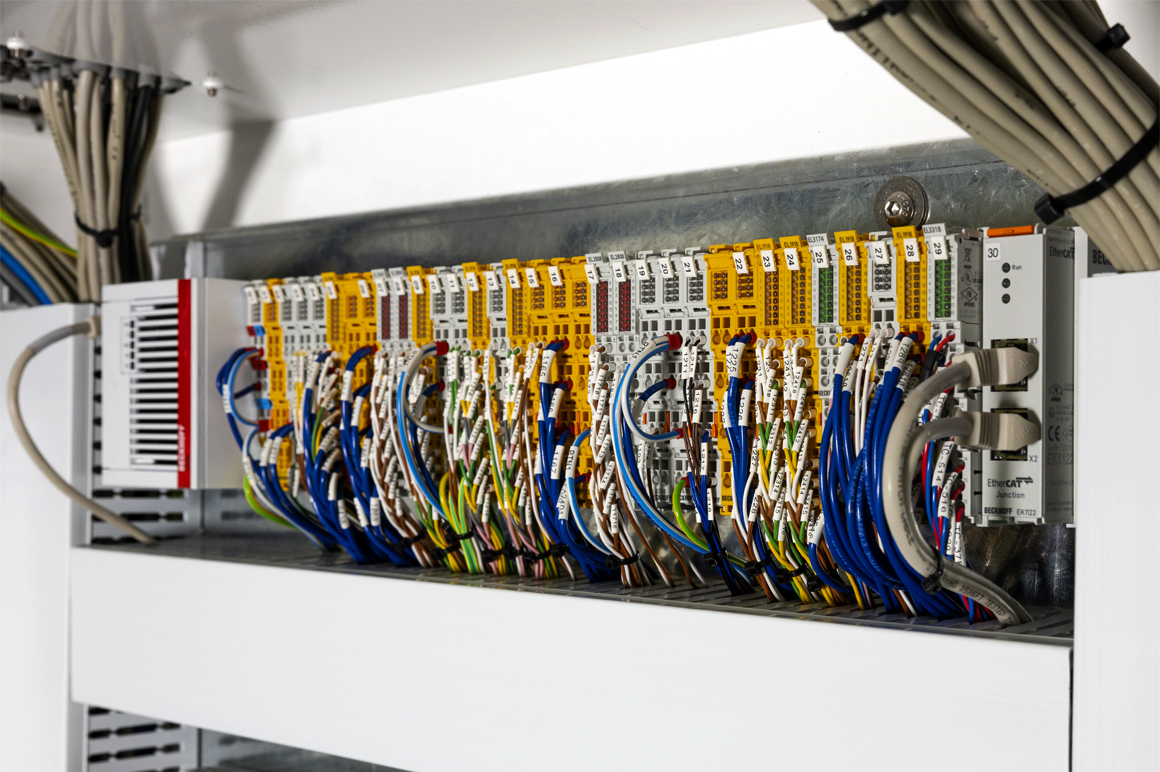

Kriss Koutzarov, Electrical Engineer at Greenlight, highlighted the technical advantages that drove their decision to select Beckhoff: “The modularity and flexibility were key factors. With Beckhoff, we had different options for I/O module channel density. Also, each module was very compact – they were just half an inch compared to five inches with other solutions. As a result, we managed to save a lot of space in the cabinet.”

To connect the hundreds of sensors, valves, and controls needed in their systems, Greenlight uses various EtherCAT input/output terminals throughout their machines. These terminals handle everything from basic valve control to sophisticated analog measurements, with systems often incorporating up to 500 data points. This modular approach allows Greenlight to easily add or modify capabilities as project requirements evolve.

Building on the safety challenges mentioned earlier, Greenlight implemented Beckhoff's TwinSAFE terminals to create comprehensive safety systems. The TwinSAFE architecture integrates digital inputs through EL1904 and EL1918 terminals and digital outputs via EL2904 and EL2912 terminals, providing Safety Integrity Level (SIL) 3 protection. Moreover, the system utilizes TwinSAFE SC terminals to monitor analog parameters such as temperature, pressure, and other critical parameters to ensure safe operation under all conditions up to SIL 2 level.

For areas with potential hydrogen exposure, Greenlight uses the Beckhoff ELX terminals with intrinsically safe inputs and outputs. These specialized terminals integrate isolation barriers and remote I/O in a single compact housing, eliminating the need for external barriers while enabling direct connection to field devices in hazardous environments up to Zone 0/20. “Wherever there might be fuel and oxidant, we must eliminate the ignition source. The ELX terminals' outputs don't have the energy to cause a spark, even if you shorted them,” says Kriss Koutzarov.

The ELX terminals provide significant space and cost advantages. With up to eight intrinsically safe inputs available in a 12 mm housing, they eliminate the need for external barriers, reducing control cabinet space requirements. Certified for ATEX, IECEx, and NEC/CEC, these terminals meet all industry-specific guidelines for explosion protection and support Greenlight's global deployments.

PC-based control simplifies system development

At the heart of their 4 MW electrolyzer test station is the CX5130 Embedded PC, which manages the entire testing process. With its dual-core processor and fanless design, the CX5130 provides the ideal balance of computing power and reliability for demanding industrial environments. This compact PC-based controller handles everything from data acquisition to complex control algorithms while offering the connectivity needed to integrate with their extensive I/O network. The ability to perform PLC and measurement tasks simultaneously makes the controller particularly well-suited for Greenlight's sophisticated test sequences, where precise timing and coordination are essential.

The system architecture leverages TwinCAT automation software for process control and the EtherCAT industrial Ethernet system for seamless integration. “It's just plug and play, which is amazing,” said Christian Bordin, Automation and Controls Developer at Greenlight, explaining the advantages of EtherCAT’s simplicity. “There’s no need for writing complex drivers. With the TwinCAT engineering environment, we can easily configure the system and communicate with all our components."

Testing the future of hydrogen production

The impact of Greenlight's standardized Beckhoff control platform has been significant for both the company and its customers. Their test stations now provide comprehensive data collection and analysis capabilities that enable manufacturers to validate and improve their system designs. One such customer, cellcentric, has found Greenlight's test stations invaluable for their fuel cell development, allowing them to evaluate performance under varying gas flow rates, humidities, temperatures, pressures, and electrical loads. Using Greenlight's Emerald software, they can develop and execute automated test scripts, view real-time data, and log precise instrumentation outputs – providing fast and reliable feedback to validate design changes and ensure product quality before shipment.

Looking ahead, Greenlight is focused on standardizing its electrolyzer test systems across a wider range of sizes. As Greenlight continues to scale, their approach remains consistent: deliver flexible, high-performance systems that let customers focus on their core technologies while Greenlight handles the complexity behind the scenes. “The key to our success has been adaptability, which allows us to meet the changing needs of this growing industry,” Christian Brosio concludes.