Transmitting high power efficiently over long distances

Interview with Dr. Fabian Assion

Sede central España

Beckhoff Automation S.A.

Interview with Dr. Fabian Assion

Power generation and distribution companies are facing huge challenges: renewable forms of energy need to be integrated, which means that flexible solutions are required to accommodate feed-in fluctuations. At the same time, there is a growing demand for extensive grid expansion and the modernization of existing infrastructure in order to move away from conventional distribution grids and toward smart grids. Increased use of automation and measurement technology is vital for achieving an efficient energy transfer. We offer innovative solutions to enable both the transparent recording of all energy flows and the control of energy systems.

Renewable energy is essential for the energy transition. However, as these forms of energy depend on external factors, such as the sun and the wind, they need flexible control technology and efficient storage solutions. Beckhoff has extensive experience in automating renewable forms of energy; more than 130,000 wind turbines have already been automated using Beckhoff control technology. Our solutions cover all functions, from operational management, pitch control, and the yaw system through to vibration monitoring, as well as farm networking. Specific software frameworks are used not only for wind energy, but also for controlling tidal turbines. Furthermore, Beckhoff technology can be found in a vast array of applications, such as solar plants, hydroelectric power stations, geothermal and biogas plants, the hydrogen industry, and electromobility.

All functions are integrated into a single platform, creating a flexible foundation for future-ready automation. These include open-loop and closed-loop control, condition monitoring, visualization, cloud connectivity, explosion protection, and safety and measurement technology. The open interfaces and support for IEC 61850 enable both conventional and renewable energy sources to be integrated into a common automation platform.

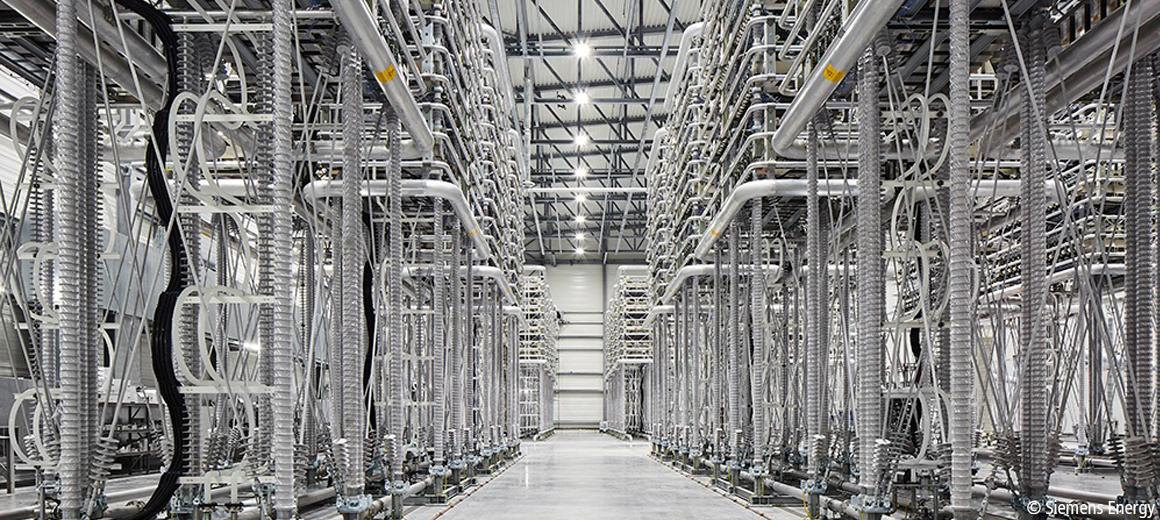

Up until a few years ago, energy only flowed in one direction through electricity grids: from generation in the extra-high and high-voltage ranges to loads in the medium and low-voltage ranges. This has now changed due to the increased share of renewable energy, meaning that energy flows have become bidirectional, generation is decentralized, and supply is uneven, which can lead to overload and instability. While conventional power plants use synchronous generators, renewable energy sources rely on inverter-controlled systems, making regulation within traditional grids a more dynamic process. Smart grids offer a solution: by providing comprehensive information on the grid’s status, they facilitate its regulation and are therefore fundamental to creating a stable and sustainable energy supply for the future.

Beckhoff offers suitable automation technology for intelligent distribution grids: EtherCAT enables precise communication with the I/O modules that are required to measure voltage and current in transformer stations and local distribution substations. Open interfaces facilitate integration into existing grid management systems. Smart grid functions can be integrated directly into the control system, enabling dynamic adaptation to changing load conditions.

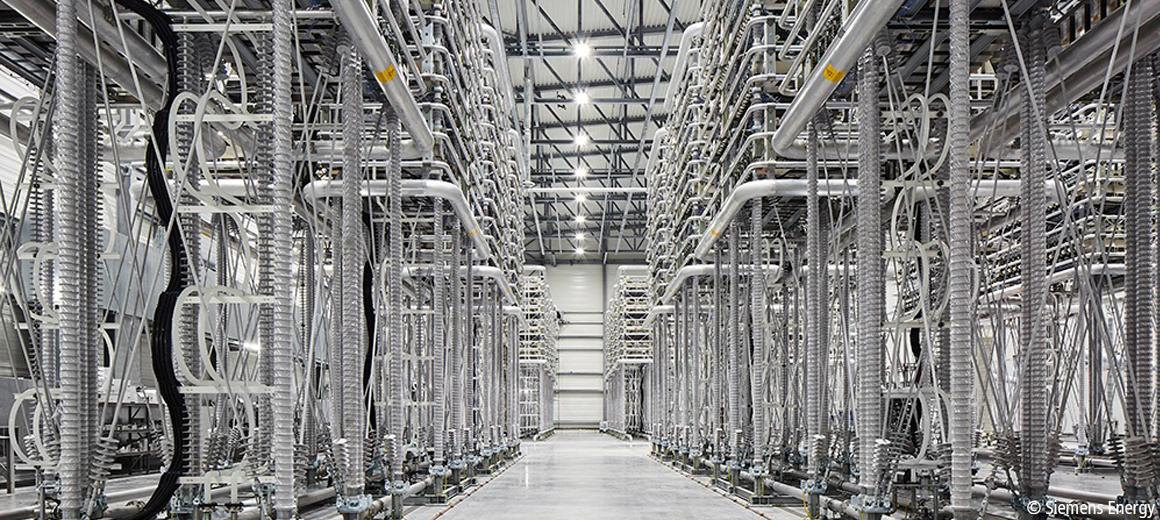

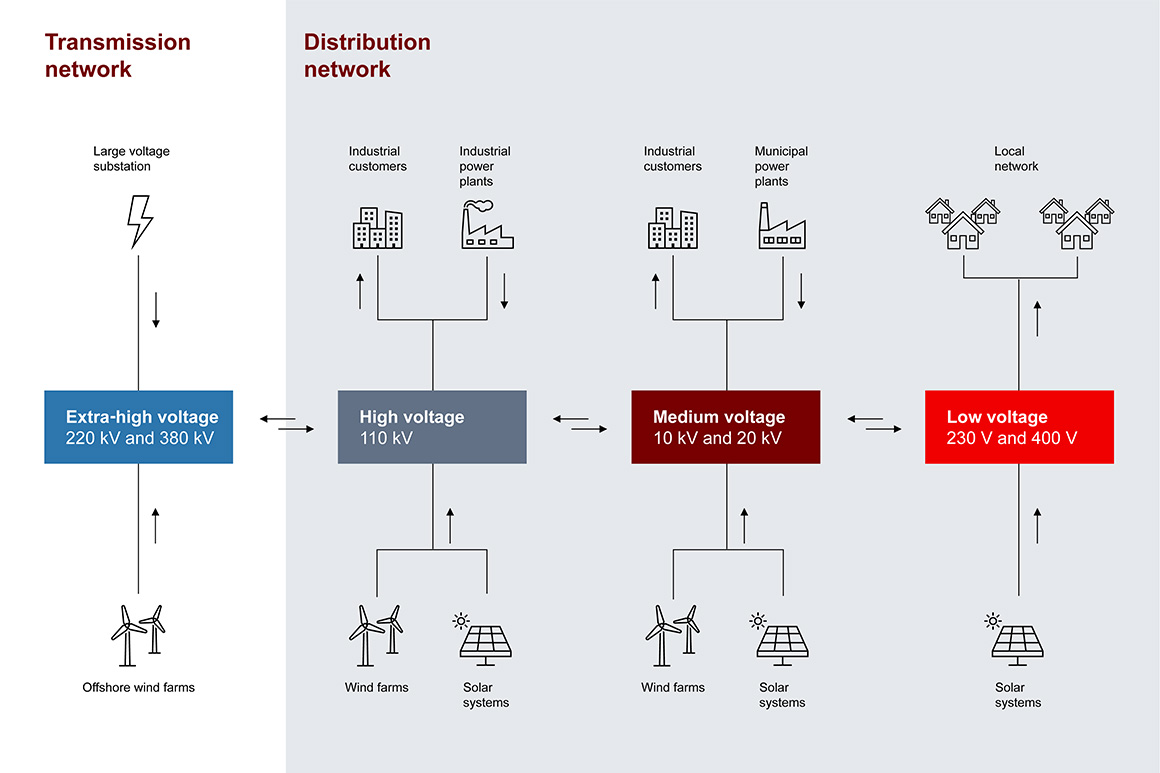

Energy needs to be transferred efficiently and with minimal losses in modern power supply systems. Beckhoff technology is used in conventional alternating current (AC) transmission systems, as well as in technologies such as high-voltage direct current (HVDC) transmission and flexible alternating current transmission systems (FACTS), which help to stabilize and optimize grid performance. The high performance of the Beckhoff control platform enables precise regulation of converter stations and power electronics. With EtherCAT, millions of measured values from I/O modules can be processed in real time to optimize line monitoring and protection mechanisms.

Beckhoff systems are scalable, allowing flexible adaptation to different transmission requirements, from individual lines to distributed grids. The ability to transfer data to the cloud securely supports real-time analysis and the development of preventive maintenance concepts. As a result of the comprehensive software solutions, even sophisticated applications, such as modular multilevel converters (MMC), can be efficiently controlled and monitored.

Energy storage systems (ESS) store energy from the grid or renewable energy sources and release it again when required. This allows energy production and consumption to take place at different times. The integration of energy storage systems enables a wide range of applications, such as grid stabilization, frequency and voltage regulation, demand response, and the integration of renewable energy. The increased volatility and reduced inertia in the grid pose a major challenge here due to the need to respond rapidly to grid disturbances. The high responsiveness of battery storage systems makes them particularly suitable for grid services such as frequency regulation and voltage stabilization.

Beckhoff offers a unified automation platform for energy storage systems, Power-to-X applications, and hydrogen systems. Powerful PCs enable precise control of charging and discharging processes, and allow monitoring of the battery status. Open interfaces mean that different storage technologies can be easily integrated and synchronized with the grid. Comprehensive software tools not only make it possible to optimize load and storage capacities, but also to use historical data for forecasting models.

In order for energy distribution to be successfully modernized, effective communication must be established between all the players in the electricity grid: conventional power plants, renewable energy generation facilities, and local systems that can consume, store, or feed in energy. Efficient networking in systems and bidirectional connectivity are crucial for decentralized systems to be able to feed power back into the grid.

Hybrid power plants (HPP) combine power generation with storage solutions at a single location and are operated as one unit. HPPs have integrated control over each system, which is optimized according to specific requirements and environmental conditions. By contrast, a local energy system (LES) controls power generation and storage in a defined geographical area, e.g., a city district. LES control focuses on balancing local generation and demand, often using more straightforward energy management systems.

Due to its high level of connectivity, PC-based control simplifies the process of networking power generation systems with control centers and grid operators. Flexible fieldbus connectivity and the integration of telecontrol protocols such as IEC 60870-5-10x and IEC 61850 enable remote monitoring and operational optimization.

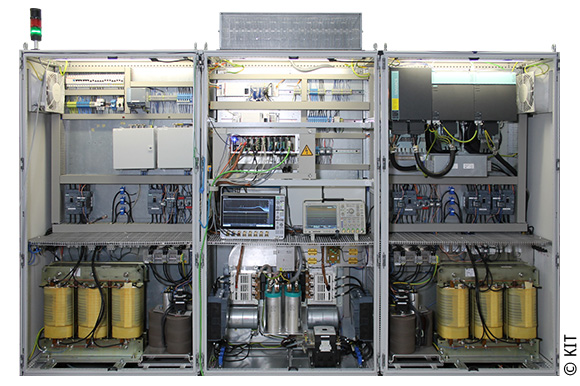

A multilevel converter (MMC) consists of numerous submodules (often half bridges or full bridges) that are connected in series to produce a stepped output voltage. This structure makes it possible to generate near-sinusoidal voltages with minimal harmonic distortion. This reduces switching losses and increases efficiency. The many submodules generate near-sinusoidal voltages while minimizing harmonic distortions. MMCs respond dynamically to grid fluctuations, supply active and reactive power, and are ideal for renewable energy sources, battery storage facilities, and HVDC systems. MMCs increase overall efficiency by reducing losses, offering high scalability, and ensuring excellent fault tolerance, as defective submodules can be isolated.

EtherCAT enables high-precision control and fast communication in MMCs, factors which are crucial for power control and energy conversion. Further advantages of PC- and EtherCAT-based converters are that they minimize harmonics, improve power quality, adapt quickly to grid fluctuations, and are highly efficient.

Ensure intelligent energy distribution with transparent monitoring of availability and demand.

Control and monitor power plants, wind farms, solar plants, and hydrogen production efficiently with PC-based control.

More than 125,000 wind turbines worldwide up to a size of 16 MW have already been automated with Beckhoff technology.

Innovative control systems for the efficient and flexible automation of hydrogen plants