Compact drive and control technology in a cosmetics filling system

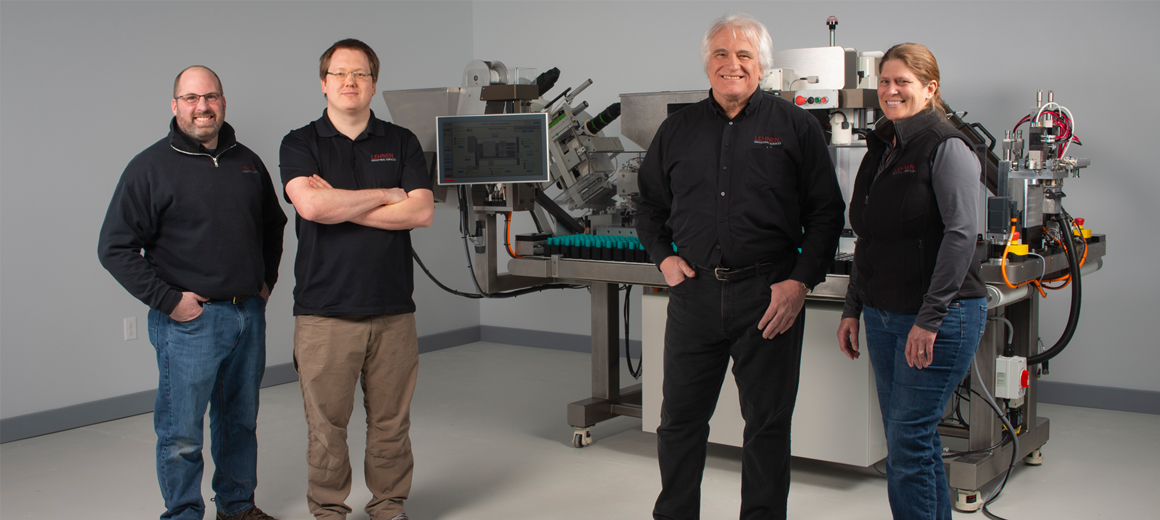

When custom machine builder Lehnen Industrial Services introduced a filling machine for lip balm, the company was surprised by the amount of interest in this premium system. In order to meet this demand, they decided to standardize the machine. The necessary adaptability is provided by the scalable control technology from Beckhoff. With an impressive range of functions on a small footprint, the system closes a gap in the life sciences market, according to the provider.

Founded in 2001, Lehnen primarily serves customers in life sciences. “Our niche is purpose-built equipment for cleanroom environments with small footprints. That involves significant design optimization to condense extensive functionality into small spaces,” President Peter Lehnen says. When the company completed its first lip balm filling system, he figured it would be the last. Sure, it combined a host of features – container loading, in-parallel filling, cooling, capping, labeling and coding – into one compact machine. But the system did not fit into any category. “With this type of filling equipment, typically one class is low cost and low speed. Then, an industrial class offers high throughput but costs millions of dollars per installation,” Peter Lehnen says. “There are few options in that middle space.”

However, when Lehnen posted a video of the ProFill SF system online, the company received inquiries right away from potential customers looking for solutions between ultra-low end and ultra-high end. As the custom machine builder from Keene, New Hampshire, decided to make the machine a standard product, the engineering team needed to answer a new challenge: how to optimize and future-proof the automation platform. Lehnen felt locked into by a legacy PLC platform that impeded innovation. “At a time when memory is so inexpensive, it’s mindboggling that a $3,000 PLC has only 4 MB of storage. So many times, I’ve been forced to delete code comments from programs just to free up enough bytes,” Head Software Developer Chris Lehnen recalls. “That, as well as arbitrary caps on I/O and motion axis counts, is why we started looking at more modern options.”

The Lehnen team first encountered Beckhoff at a trade show in 2015, but at the time they weren’t ready to navigate a platform shift that was not going to be easy in the strongly regulated life sciences industry. Then in 2020, as many vendors struggled to supply components, they found out how flexible the Beckhoff platform can be adapted by making component substitutions. These factors allowed them to migrate some customer projects to Beckhoff – at the same time as the machine builder started considering manufacturing standard filling systems.

Innovation through flexible automation

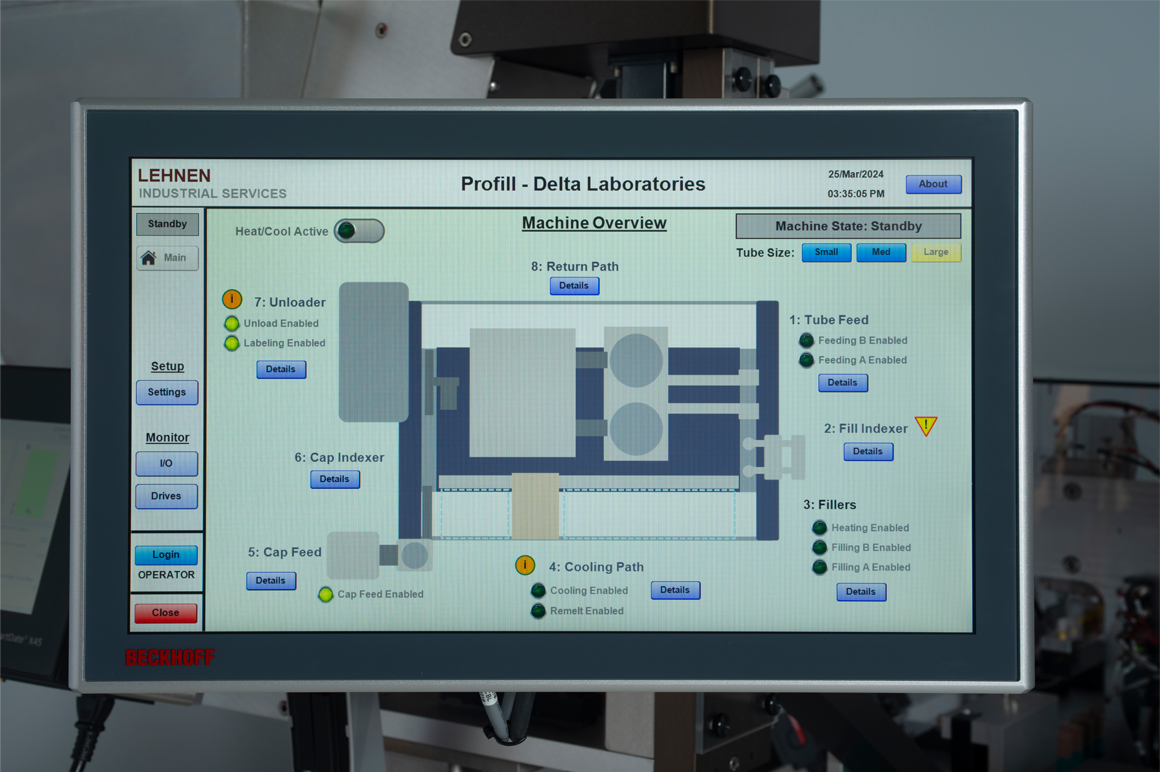

The ProFill system brings all processing steps into a self-contained unit measuring just 11 feet 8 inches by 5 feet 5 inches (308 x 142 cm). Even with its sturdy stainless steel construction, the portable system can move on casters to work in any location with compressed air and 240-V AC connections. In addition, the design simplifies filling head changes, whether for cleaning or product changeovers.

During the development process of a standard system the engineers wanted to ensure that the machine would maintain its small footprint and high-precision filling to avoid dripping hard-to-clean, waxy liquid on conveyance equipment. Working with the local team from Beckhoff USA, including Regional Sales Engineer Brian Buck and Applications Engineer Matt Kleven, Lehnen began the redesign in January 2023.

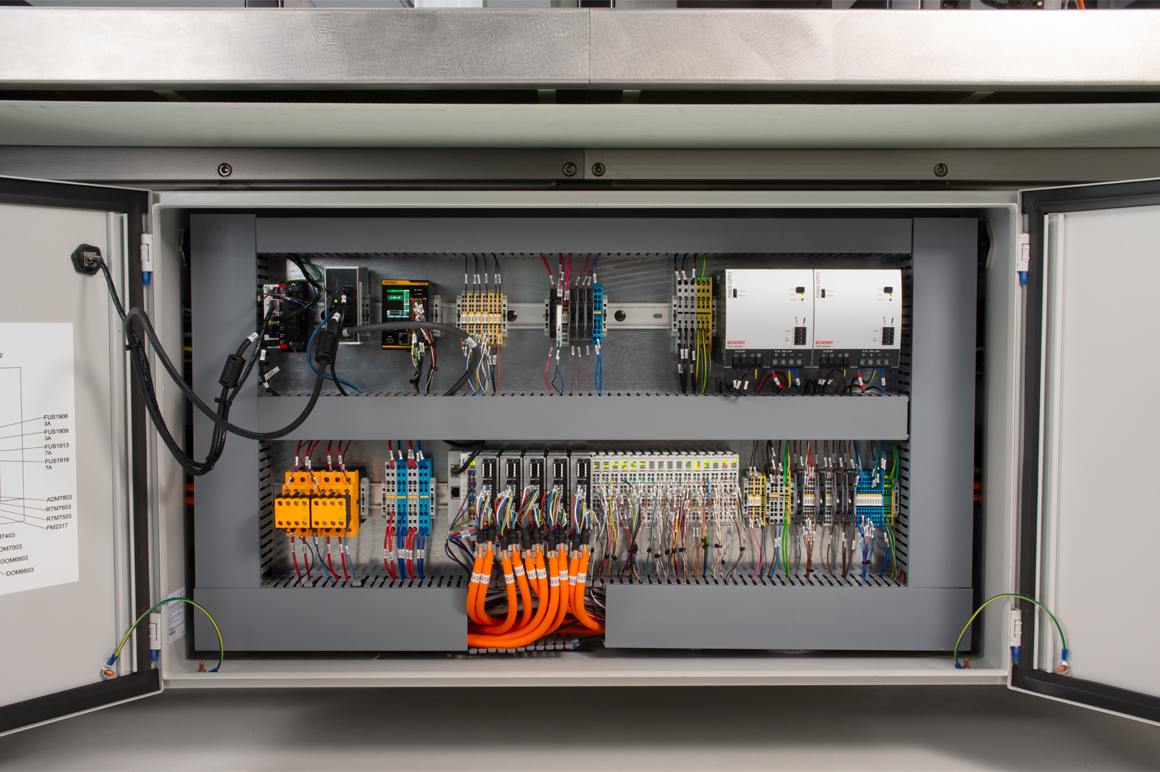

The system relies on a C6015 ultra-compact Industrial PC (IPC) as its machine controller. Beyond its extremely space-saving dimensions, the IPC’s memory options range from 40 to 320 gigabytes. A CP3918 multi-touch Control Panel from Beckhoff brings intuitive smartphone-style operation even to tough production environments.

Programming of the HMI, PLC and motion control takes place in TwinCAT 3 automation software. As an end-to-end engineering and runtime platform, TwinCAT incorporates all functionality needed for machine control with flexible options for writing code. The integration into Microsoft Visual Studio means engineers can leverage the programming language that best fits, including:

- IEC 61131-3 standards with object-oriented extensions

- custom function blocks or hundreds of built-in options in TwinCAT libraries

- computer science paradigms, such as C#, C++, Python, and HTML5 or JavaScript for HMI creation

The Lehnen team appreciates the ability to try software in the no-cost TwinCAT engineering environment before buying it. “TwinCAT offers a proper implementation of the IEC standard and object-oriented programming, unlike other vendors’ platforms that are technically compliant but more restrictive. This allows us to truly embrace best practices in software development,” Chris Lehnen says. “Beyond that, TwinCAT simplifies source code control through incorporation of Git. So our software team can work on the same program simultaneously to speed up development.”

“The Lehnen team really took advantage of numerous software and hardware solutions we offer, including the precise synchronization with EtherCAT,” says Brian Buck. “For me, an aspect of this application that stands out is their use of the compact ELM7222 servo drives.” The dual-channel, 48-V DC servo amplifiers can be installed directly within the EtherCAT I/O segment, as they are EtherCAT Terminals that measure just 30 mm wide, alongside wide-ranging terminals needed for networking the system, such as high-density inputs and outputs, analog temperature measurement and thermocouple modules.

The ELM72xx series servo terminals also support One Cable Technology (OCT) to connect AM8100 servomotors from Beckhoff with a minimized cabling effort. These features further shrink space requirements and simplify commissioning, while ensuring very high performance.

Potential for future expansion

The standardized lip balm filler maintained its high performance and compact footprint. The system processes trays of eight tubes at a time with a throughput of 60 tubes per minute. In continuous operation, the machine can fill, cap, label and serial code 30,000 sticks per day.

With space-saving controls, networking and servo drive hardware from Beckhoff, the machine also freed up space in the electrical cabinet for future functionality additions. “On top of having a better overall system, we reduced costs significantly,” Peter Lehnen says. “In terms of control hardware, we saved roughly 40% by standardizing on Beckhoff.”