PC-Based control optimizes parts handling on plastics machinery

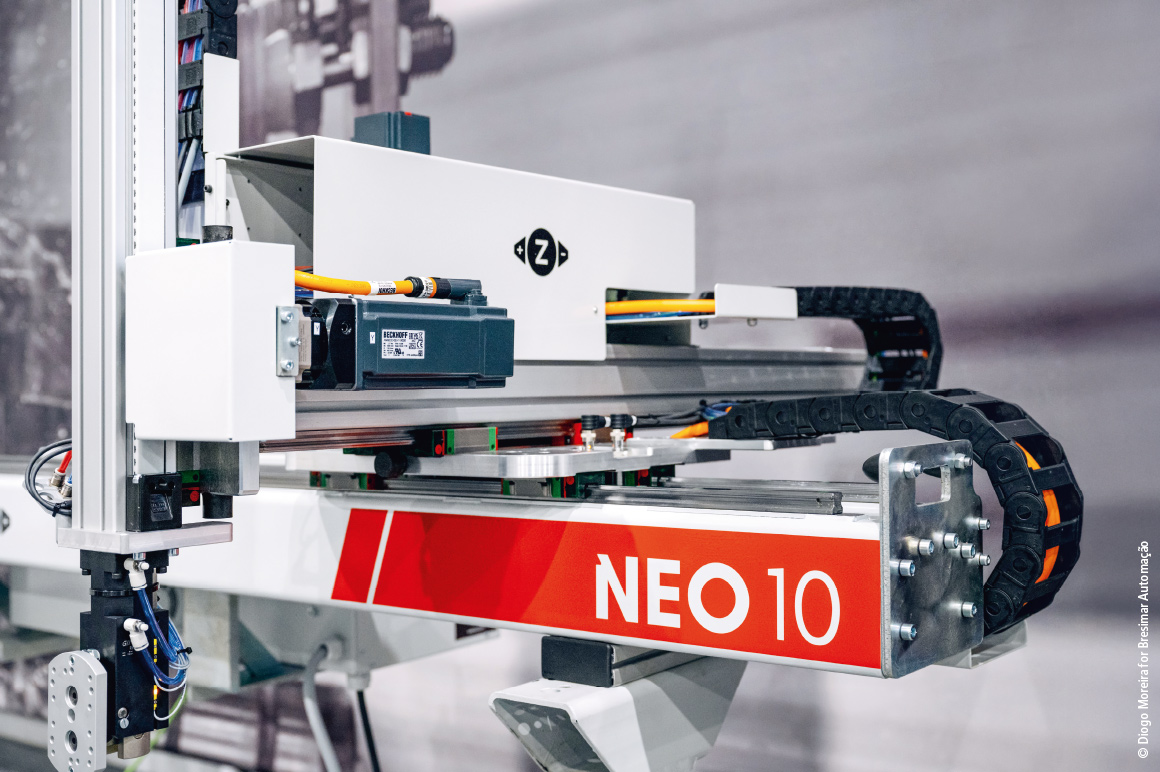

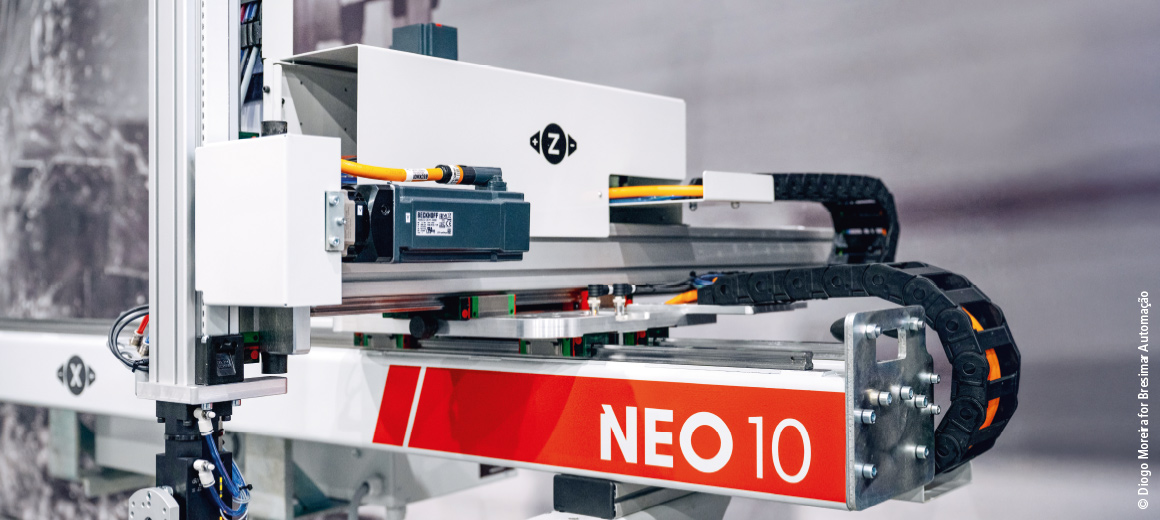

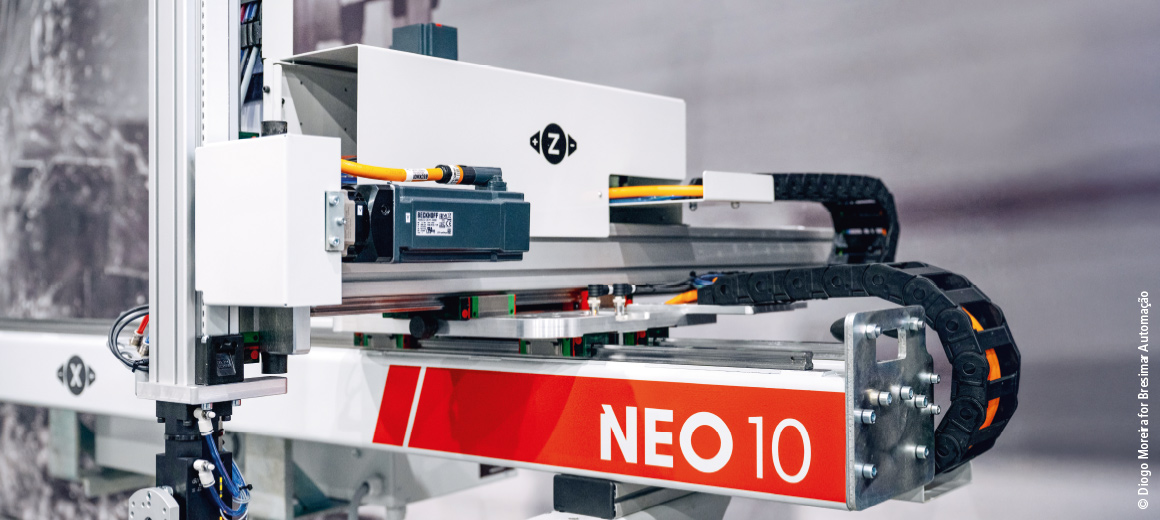

NEO is a cartesian robot developed entirely by INAUTOM Robótica in Portugal for parts removal on plastics machinery. Its aim is to increase system productivity. The company relied on AM8000 synchronous servomotors, the AX8000 multi-axis servo system, TwinCAT software, and the expertise of the long-standing Beckhoff distributor Bresimar Automação to create this robot.

The plastics industry is faced with the challenge of constantly increasing the efficiency and flexibility of its machines and processes. “This makes automation an essential factor in keeping machine suppliers and producers competitive,” says Fábio Roleiro, Development Engineer at INAUTOM Robótica, emphasizing the importance of the project. With this in mind, INAUTOM Robótica – which is the only portuguese company specialized in the production and integration of cartesian robots and other types of robotic solutions into plastic injection molding machines – has entered into a strategic partnership with Bresimar Automação, a company that has represented Beckhoff Automation in Portugal for more than 20 years. The aim of the collaboration was to increase the working speed of the cartesian robots using advanced control and motion solutions from Beckhoff. “As a result, we’ve created a comprehensive, future-proof automation solution for our entire family of cartesian robots,” says Fábio Roleiro.

Flexibility thanks to an open automation system

The cartesian robots in the NEO series are optimized for the fast and precise removal of injection molded parts, thus increasing machine productivity. Key performance indicators such as high removal and placement accuracy and speed are crucial elements in reducing cycle time. All the components of the cartesian robots have been designed to ensure the system is mechanically robust enough for integration into plastics machines.

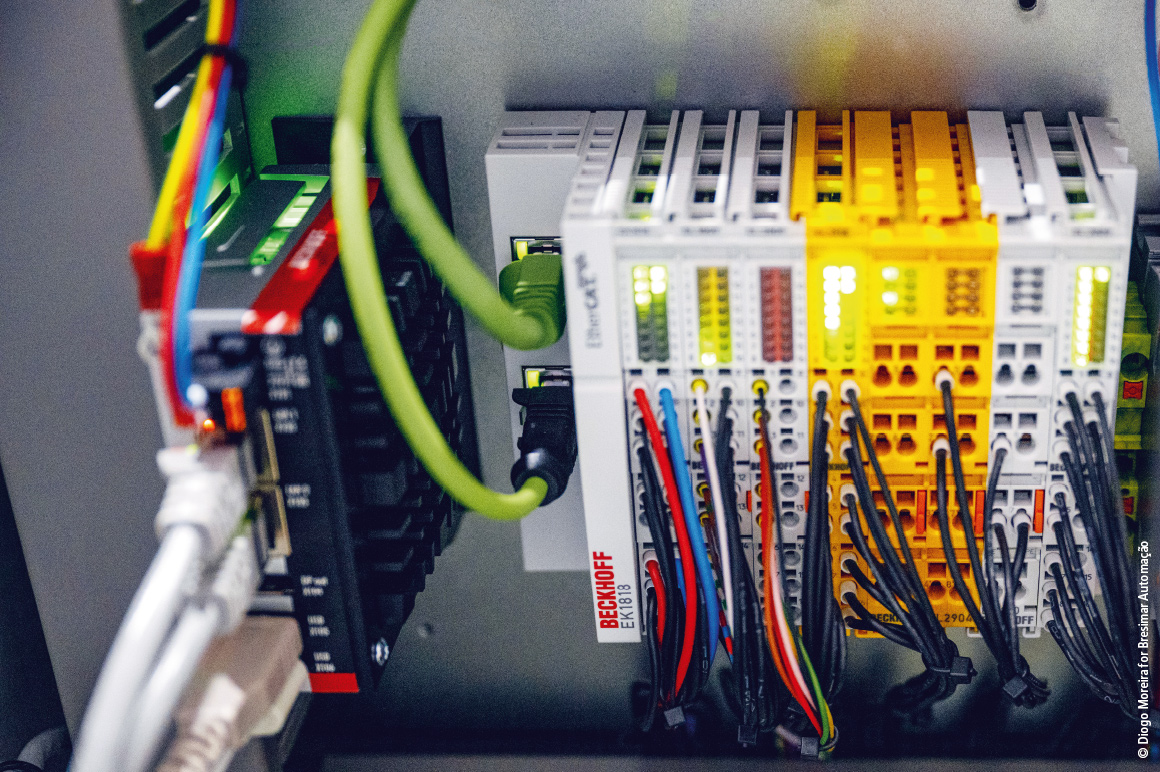

The components that the company relies on include a C6015 ultra-compact Industrial PC as the controller, AM8000 synchronous servomotors in combination with the AX8000 multi-axis servo system, and various EtherCAT Terminals from the EL series and EtherCAT Box modules from the EP series. “Working with these plus TwinCAT 3 as the automation platform, the engineers at INAUTOM Robótica were able to deal with all the technical challenges they were faced with,” says Gervásio Monteiro, Beckhoff Brand Manager at Bresimar Automação.

An important aspect in the development of the NEO series was to achieve the greatest possible flexibility so that handling solutions could be adapted to customer layouts and processes. “With payloads of up to 70 kg, the cartesian robots are also a great option for applications outside the plastics industry,” says Fábio Roleiro, highlighting the wide range of applications for the series.

The finely graduated portfolio of motors and drives enables adaptation to different payloads. In terms of the software, standardization across all sizes was achieved thanks to TwinCAT. To achieve precise movements that also meet the high requirements placed on speed and acceleration, the gantry axes (X, Y, and Z) are equipped with AM8000 synchronous servomotors. With their dynamics and high holding torques, the servomotors are ideal for applications that require precision and efficiency. Encoders integrated into the servomotors as a feedback system provide precise position values, which are transmitted to the AX8000 multi-axis servo system in real time (communication cycle of 62.5 µs) via EtherCAT and the space-saving, weight-reducing One Cable Technology (OCT) connection technology.

Adaptable hardware and software

With dimensions of just 82 x 82 x 40 mm, the C6015 ultra-compact Industrial PC is the most compact model in this series from Beckhoff. It also provides versatile installation options. “INAUTOM Robótica exploits limited installation space with the industrial PC,” says Gervásio Monteiro. Despite the small form factor, Intel Atom® quad-core processors provide sufficient computing power to calculate the axis movements of the cartesian robot dynamically and synchronously with TwinCAT. “With Windows 10 IoT and TwinCAT/BSD operating systems available, as well as Linux® in the future, we can also adapt to the software requirements and operating environments of our customers,” says Fábio Roleiro, emphasizing the flexibility of the NEO series.

INAUTOM Robótica automates the robots with a TwinCAT 3 PLC/NC PTP 10 (TC1250) and the TwinCAT 3 HMI server (TF2000) for visualization. The user interface developed in HTML5 provides a complete solution for managing and operating the robot systems. HTML5 enables both combination with mobile operating devices and integration into an existing browser-based HMI for plastics machinery. This saves on the cost of an additional device for commissioning the robot. “In addition, the HTML5-based visualization simplifies user interaction with the system. The intuitive operation reduces the learning curve for operating personnel, which means that it also helps increase efficiency overall,” says Gervásio Monteiro. Additionally, PC-based control as an open control platform gives INAUTOM Robótica the assurance that it will be able to accommodate future customer requirements as well.

Safety in accordance with IEC 61508 and Euromap 67

INAUTOM Robótica relies on TwinSAFE as its safety technology for implementing safety requirements in accordance with IEC 61508 (SIL3). It uses EL1918 TwinSAFE Terminals (4-channel digital input) and an EL2904 (4-channel digital output). This means that the robots can be integrated into the plastics machines in accordance with the Euromap 67 standard (Electrical Interface between Injection Moulding Machine and Handling Device/Robot). “This standard is essential for the safe electrification and coding of robot operations,” states Fábio Roleiro.

“The solution based on drive and control technology from Beckhoff exceeds our performance requirements and meets the high safety standards set out by IEC 61508 (SIL3) and Euromap 67,” says Fábio Roleiro in summary. Integrating Beckhoff’s control and drive technology into INAUTOM Robótica’s cartesian robots enables pick-and-place operations to achieve higher levels of speed and accuracy. INAUTOM Robótica’s customers benefit from reduced cycle times, resulting in a significant improvement in the productivity of plastic injection molding machines. This is because the modular design of the NEO robots allows them to be customized to specific customer layouts and processes in terms of payloads and dimensions. “Our project shows how important exceptional technologies are for meeting specific market requirements,” explains Fábio Roleiro, “and that strategic partnerships and innovation play a crucial role in the continuous development of industrial automation.”