PC-based control in the plastics industry

Utilizing in-house developed control devices to balance advanced control technology with cost efficiency is an approach that has long prevailed among plastics machinery manufacturers. However, it hit its limits a while ago. Factors such as labor shortages, financial challenges, and the need to adapt to the latest technologies have resulted in a trend for open automation systems from experienced specialists. Nissei Plastic Industrial Co., Ltd. (Nissei Plastic), an injection molding machine manufacturer based in Nagano Prefecture, Japan, is implementing this shift using PC and EtherCAT-based control technology from Beckhoff.

The German Industrie 4.0 initiative, which highlights the importance of standardization and interconnectivity in manufacturing, underpins the success of control platforms with open architecture. Across various industries, including the field of injection molding machines, concrete implementation is gaining momentum. Notably, OPC Unified Architecture (OPC UA) has become the primary communication framework for Industrie 4.0 standardization. In this context, Nissei Plastic has taken what it describes as a pioneering step: developing an advanced control system based on Beckhoff Industrial PCs with TwinCAT software and EtherCAT open communication technology. Moreover, Nissei Plastic became one of the first manufacturers worldwide to meet the requirements of the OPC UA standard.

Why opt for an open architecture?

Plastics are an essential material used in products such as smartphones, televisions, PCs, and automotive components. Depending on the size and type of final product, the injection molding machines required for production range from compact to massive systems with clamping forces exceeding 7,000 tons. Nissei Plastic is one of the world’s leading manufacturers of such injection molding machines and regards the transition of its control platform to an open architecture as a pivotal decision.

Like many other manufacturers, Nissei Plastic originally developed in-house microcontroller boards for their customized control systems. However, this approach required the company to manage all hardware components internally, presenting a considerable challenge. They had to address issues such as component discontinuation, revision changes, and technical problems unrelated to their primary expertise in injection molding technology. Moreover, keeping up with the latest CPU technology updates added to their concerns, necessitating constant hardware development. Nissei Plastic therefore decided to focus its resources on software development and use scalable standard control hardware.

Selecting PC and EtherCAT-based control as the solution

After comprehensive benchmarking, Nissei Plastic found that Beckhoff’s PC-based control in combination with the open and fast EtherCAT communication system was best suited to meet its current and future demands. The main reasons for this decision included:

- High performance: The production of injection molded parts with maximum repeatability and high quality requires a highly deterministic control system with cycle times of 125 µs or lower. According to the experts at Nissei Plastic, PC-based control from Beckhoff offers the required performance, not least due to its in-depth development and production expertise. This is because Beckhoff develops and manufactures the IPC motherboards in-house, creates the TwinCAT automation software for real-time control, and utilizes its unparalleled expertise in fieldbus communication as the inventor of EtherCAT. This extensive and long-standing experience is crucial.

- EtherCAT: Specifically in Japan, EtherCAT has been a de facto standard for many years. This offers Nissei Plastic significant flexibility in selecting the most suitable suppliers and components for its injection molding machines. Collaborating with Beckhoff ensures Nissei receives top-notch support for any EtherCAT-related queries and early access to future cost-saving EtherCAT technologies, such as EtherCAT P. EtherCAT emerged as the only technology capable of delivering the required speed and accuracy while maintaining high flexibility and broad fieldbus coverage. Moreover, the scalability of EtherCAT facilitates future system expansions and upgrades, increasing the company’s investment security.

According to Nissei Plastic, in order to remain competitive in the plastics industry, it is crucial to develop cost-efficient machines in terms of engineering, production, and maintenance. In addition to leveraging economies of scale when relying on standard automation hardware, PC-based control from Beckhoff offers various options for minimizing overall costs:

- Centralized and scalable control hardware: The Beckhoff control system is based on a centralized and finely scalable computer platform. As a result, it is possible to choose from a broad CPU portfolio to match the application-specific requirements. If new functions such as machine learning are added, these additional functions can be programmed in TwinCAT in various programming languages including IEC 61131-3, C++ or MATLAB® and Simulink® and then executed as software modules in real time. If higher computing power is required, this can be easily accomplished by migrating to a new IPC or CPU version without changing the existing TwinCAT project or the intended automation architecture.

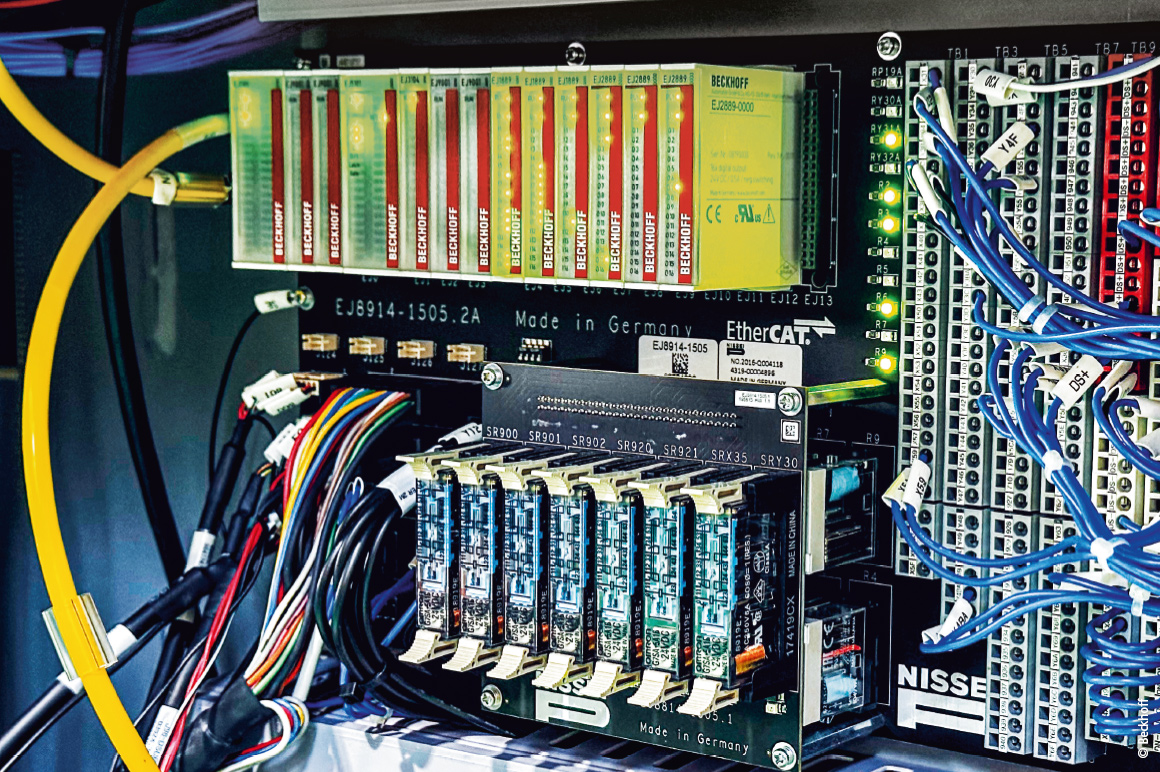

- EtherCAT plug-in modules: Nissei Plastic sees great advantages in the EtherCAT plug-in modules of the EJ series, which integrate several I/O functions into a single compact board – the signal distribution board. This shortens the development and time-to-market times, as the standardized signal distribution board can be used to implement different machine types with expansion variants on a single basis. Furthermore, this approach eliminates wiring costs and errors and provides a simple means of customization by plugging in new modules without having to completely redevelop the board – offering significant benefits for the company.

Converting standard machines to PC-based control

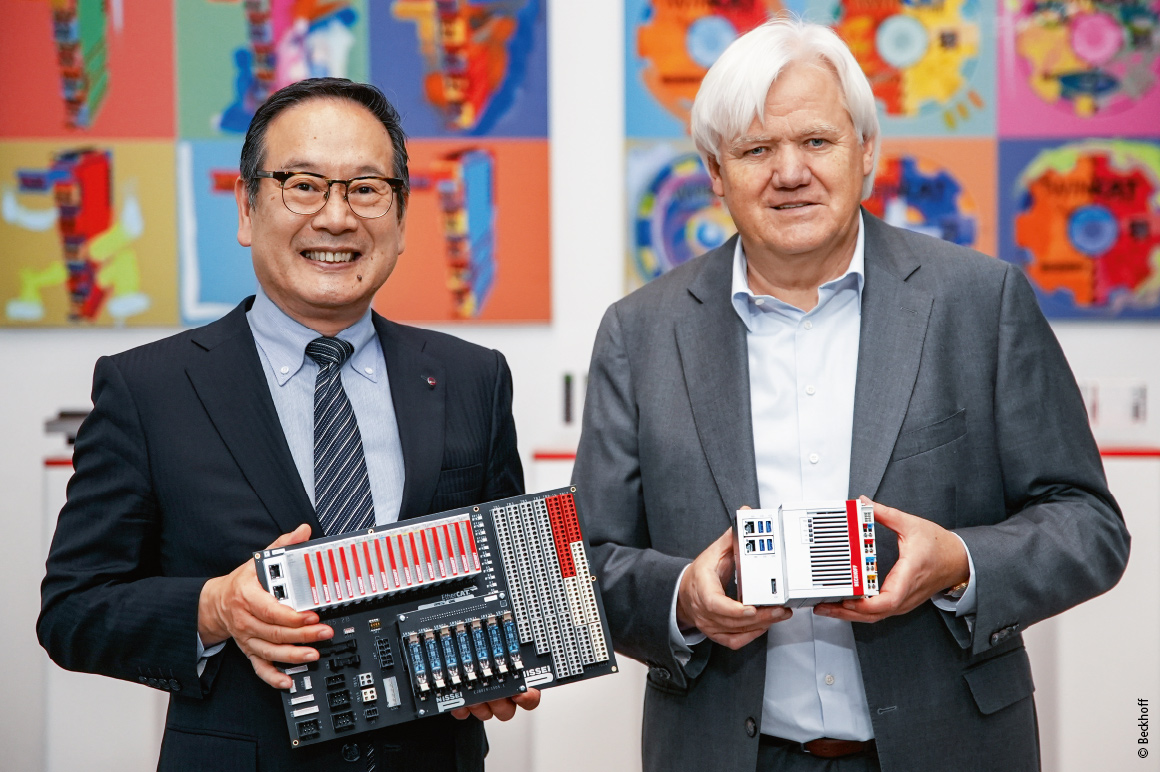

The development of EtherCAT-compatible injection molding machines equipped with Beckhoff technology began back in 2016. The following year – and then globally in 2018 while announcing its partnership with Beckhoff – Nissei Plastic unveiled the new machine model FNX-IV (hydraulic version) in Japan. This marked the first milestone of integrating Beckhoff technology into its machines. Subsequently, the electric NEX-V series was introduced, meaning that all series-produced machines from Nissei Plastic now feature Beckhoff technology.

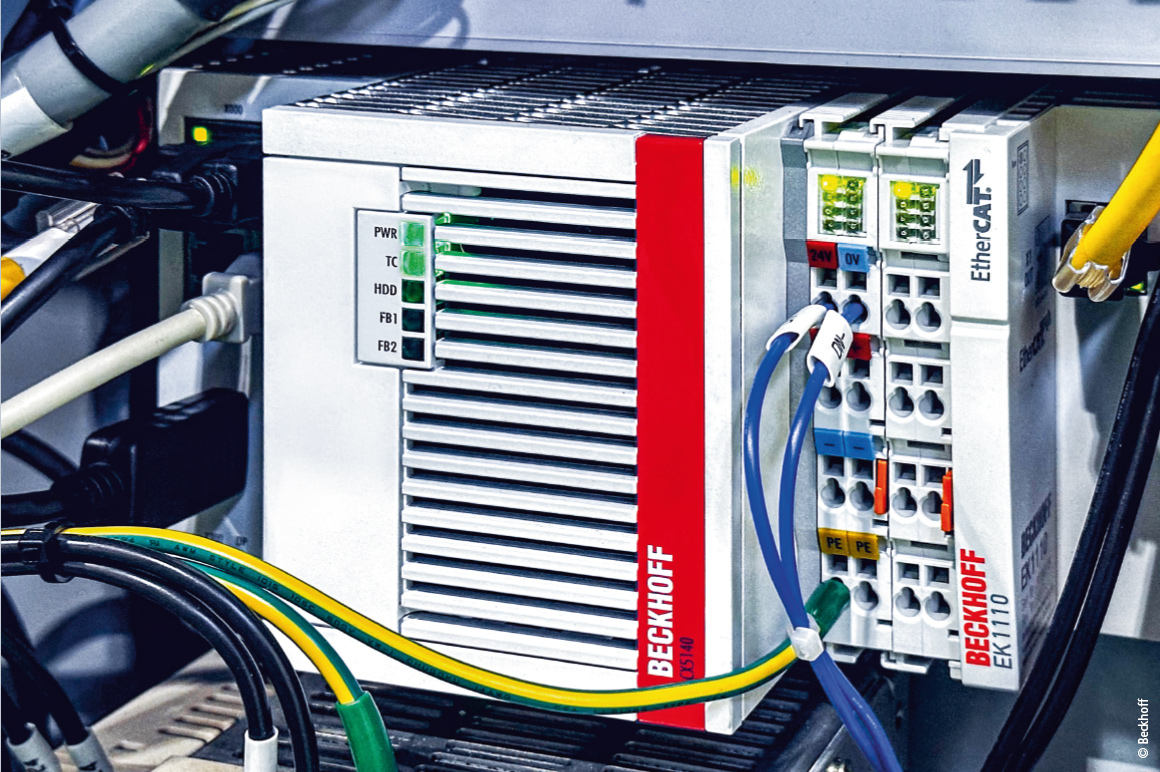

The FNX-IV and NEX-V models use the cost-efficient CX5140 Embedded PC with a quad-core Intel Atom® processor as the control core. This PC serves as the EtherCAT master, enabling extremely fast control cycles. Previously, analog communication limited the speed and precision of control. According to Nissei Plastic, however, switching to EtherCAT allowed all applications, including peripheral devices, to be fully integrated into a high-speed network, significantly improving precision, noise resistance, and molding quality.

Additionally, TwinCAT allowed various functions to be integrated into PC-based control modules, ensuring future scalability without hardware modifications. Nissei Plastic also values the open nature of TwinCAT as an engineering environment, e.g., with a wide range of options for integrating existing source code. TwinCAT 3 C++ converts many of the software assets previously used on the self-developed microcontroller board directly into new control modules. These modules are combined with TwinCAT 3 PLC to create a new control system with minimal effort. As a result, Nissei Plastic has succeeded in developing a highly flexible system in a short space of time.

Nissei Plastic’s IoT strategy

Inspired by the German Industry 4.0 initiative, industries worldwide are working towards standardized data interoperability across manufacturers. The central framework for this movement is OPC UA, but it does not fully address the needs of all production plants. To close this gap, industry-specific companion specifications have been developed in different sectors:

- plastics machinery: EUROMAP

- machine tools: umati

- industrial robots: OPC UA for Robotics

- packaging machines: PackML

Recognizing the urgency of OPC UA adoption, Nissei Plastic led the way, presenting an OPC UA-based EUROMAP solution together with Beckhoff back in 2018. In 2019, the machine builder launched its new TACT5 controller with OPC UA as a standard feature. According to Nissei Plastic, this open technology approach not only offers greater benefits for the user, but also fosters collaboration across Japan’s plastics industry and ensures long-term competitiveness.

Partnership with Beckhoff

Nissei Plastic has high expectations for its partnership with Beckhoff. Moving forward, the company seeks deeper collaboration with Beckhoff, including beta testing new products to optimize cost and performance. Nissei Plastic attaches great importance to a long-term, trusting, and cooperative business relationship. In addition to sales and technical support from local Beckhoff experts in all relevant production countries, this also includes close contact with various Beckhoff specialist departments.