Beckhoff at Fachpack 2025

September 23 ̵ 25 | Nuremberg | Hall 3C, Booth 354 | Ticket code: A548389

สำนักงานผู้แทนประเทศไทย

September 23 ̵ 25 | Nuremberg | Hall 3C, Booth 354 | Ticket code: A548389

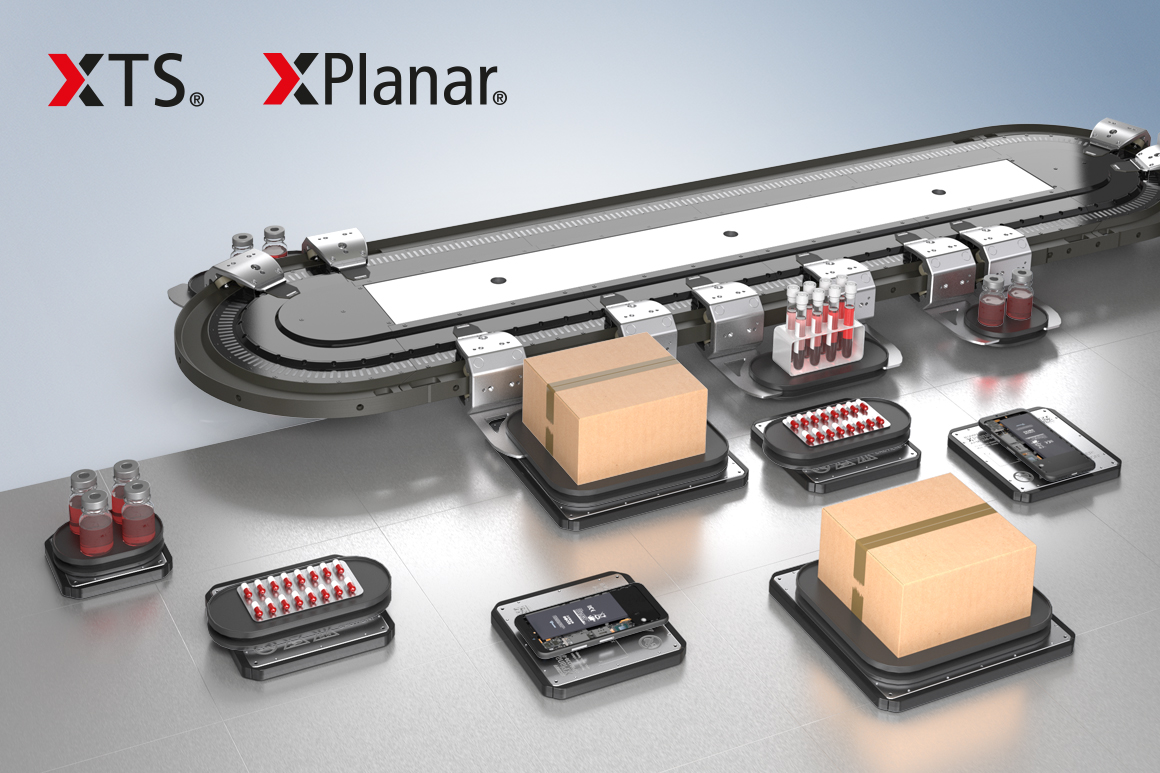

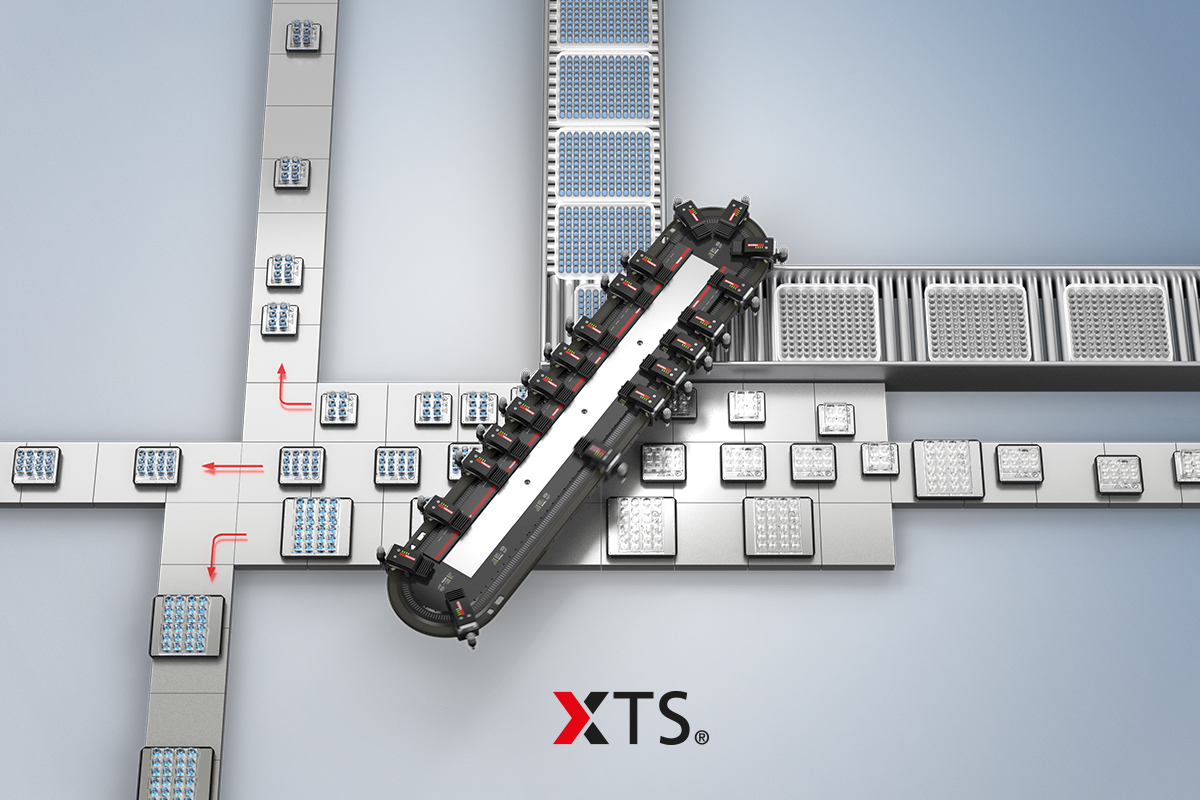

How can you pack a rapidly expanding number of products while conserving resources and energy? This is the main challenge that the packaging industry faces today. Beckhoff will present high-performance solutions that help you overcome this and other issues from September 23 to 25 at FACHPACK 2025 in Nuremberg. These solutions include TwinCAT CoAgent, which helps you save valuable resources right from the engineering stage. TwinCAT MC3 is the next generation of motion control that lays the foundations for your sustainable packaging processes, together with a wide range of drive solutions, intelligent transport systems such as XPlanar and XTS with NCT, and system-integrated Beckhoff Vision. Our Next multi-touch control panels are sure to be the ideal match for your system. Discover our comprehensive portfolio at FACHPACK, allow us to explain its advantages in detail, and see how perfect PC-based control is for your packaging machinery yourself.

Book your free ticket using the code A548389 and meet us in Hall 3C at Booth 354.

We are looking forward to your visit!

The XPlanar planar motor system:

The XTS eXtended Transport System and XTS Hygienic:

Hülshorstweg 20

33415 Verl

Germany

+49 5246 963-0

info@beckhoff.com

www.beckhoff.com/en-en/