PC-based control technology in large telescopes

The Instituto de Astrofisica de Canarias (IAC – Institute of Astrophysics of the Canary Islands), a research institute at the University of La Laguna, Spain, operates two astronomical observatories on the Canary Islands: the Roque de los Muchachos Observatory on La Palma and the Teide Observatory on Tenerife. PC-based control and motion control from Beckhoff enable astrophysicists to explore the limits of space.

The partnership between IAC and Beckhoff began with the first telescope for the Q-U-I Joint Tenerife Experiment (QUIJOTE I) over twelve years ago. Its aim was to characterize the polarization of the cosmic microwave background (CMB) and other galactic and extragalactic emission processes in frequency ranges from 10 to 42 GHz, and to discover traces of the Big Bang in this way. Beckhoff Automation was chosen as the partner for the telescope’s control technology – and is still a valued partner today.

Precision with motion control and EtherCAT

The telescope’s control system is based on TwinCAT 2 NC PTP and a C5102 19-inch slide-in Industrial PC which precisely controls the azimuth and elevation of the telescope. In addition to the digital and analog inputs and outputs required to control the telescope, the EL6688 (IEEE 1588/PTP) communication interface facilitated the programming and implementation of the Precision Time Protocol. This EtherCAT Terminal supports PTPv1 (IEEE 1588-2002) and PTPv2 (IEEE 1588-2008) as a device in the IEEE 1588 synchronization system. “Clock synchronization is crucial for synchronizing telescopes very precisely with the movements of the stars and galaxies being observed,” states Jose Miguel Herreros, Engineering Director of IAC. Another major challenge was moving the axes with exceptional precision at both very slow speeds and higher speeds. The reason for this was the significant moment of inertia on the direct drive of the azimuth axis, which required extensive adjustments to the speed controller in the AX2000 servo drive used at the time, recalls Roberto Iraola, Sales Manager Beckhoff, who adds: “This was fundamental to the project’s success.”

This project was followed by the QUIJOTE II telescope for the TFGI (Thirty and Forty GHz Instrument), which consists of a total of 30 receivers. AX5000 digital compact servo drives were already in use with this telescope. Beckhoff developed both telescopes in close cooperation with Spanish company IDOM, while IAC employees developed the control software. In 2022, both control systems were migrated to TwinCAT 3 and C5240 19-inch slide-in Industrial PCs. “We are currently working with Beckhoff on many projects such as ‘Harmoni’ for the Extremely Large Telescope (ELT), robotic telescopes, and various instruments mounted on these telescopes,” says Jose Miguel Herreros.

Extensive modernization

The Carlos Sánchez (TCS) and IAC80 telescopes at the Teide Observatory on Tenerife are manually controlled by astronomers using computer applications that were developed back in the 1990s. In addition to motion control, these applications control subsystems such as the dome, windows, gates, and covers, and monitor the weather station, alarms, and GPS signals. This control system initially consisted of a PC with plug-in cards for communication with the subsystems. It was operated using another PC, which communicated with the control computer via RS232. Although some modernization measures have been carried out, a large part of the control system is still based on components that are now completely outdated.

A project that started in mid-2019 and has not yet been completed aims to migrate the control systems of these telescopes to state-of-the-art, robust software and hardware, and to implement advanced remote control in the process. This future high-level control software will be based on the ROS (Robot Operating System) open-source operating system, while the underlying control architecture will be based on EtherCAT and TwinCAT 3 from Beckhoff. To reduce the possibility of technical risks affecting the project, the team developed a telescope simulator to represent the telescopes’ drive system and data network, and provide a virtual test bed for developing and testing the new system – which will not be implemented at telescope level until extensive testing has been performed. Additionally, an ongoing investigation is assessing the suitability of TwinCAT Vision for automatic star tracking by telescope. An autoguiding system has been selected for testing and can also be used for other telescope tracking systems.

Different site, same technology

The Roque de los Muchachos Observatory (ORM) on the edge of the Caldera de Taburiente National Park, sitting at an altitude of 2396 m in the municipality of Garafía (La Palma), boasts one of the most comprehensive telescope technologies in the world. Thanks to the clear atmosphere and its location far away from disruptive light waves, the observatory offers ideal conditions for astronomical research. This is why the location has been home to some of the largest-ever telescope projects – as well as the new generation of Cherenkov telescopes for exploring the universe using very high-energy gamma rays.

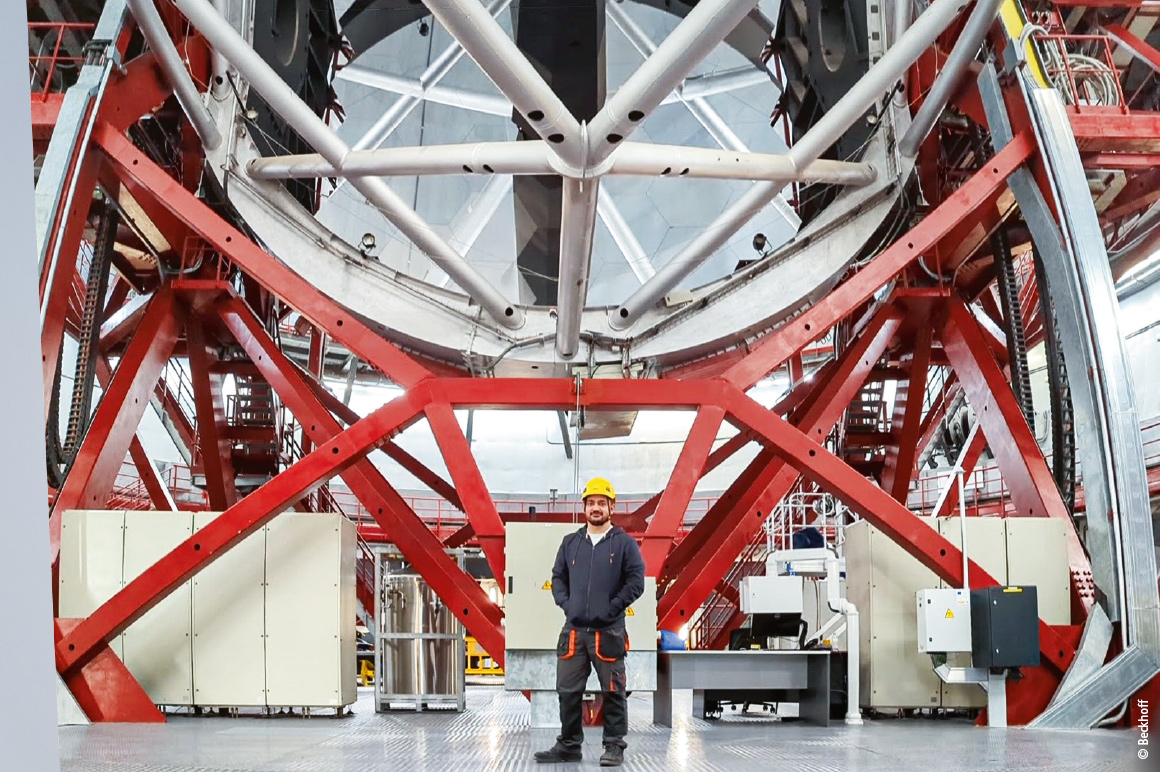

The observatory operates what is currently the world’s largest optical and infrared telescope, the Gran Telescopio de Canarias (GTC), alongside twenty other telescopes and astronomical instruments for applications such as nocturnal, robotic, solar, and astrophysical observations involving high energy. These telescopes have already made significant progress in exploring the universe: for example, identifying the most distant galaxy or confirming the existence of black holes and the accelerated expansion of the universe.

A superlative telescope

With a mirror diameter spanning 10.4 m, the GTC is the largest telescope at this observatory. Its planning phase began in 1994 and the GTC was put into scientific operation around 15 years later in 2009. As the technology of the control system specified at the time eventually became outdated, it has since been replaced by PC-based control. This occasion also enabled subsystems such as building automation and lighting systems to be integrated. “We have been able to implement these subsystems thanks to Beckhoff’s open PC-based technology and its experience in building automation,” explains Roberto Iraola.

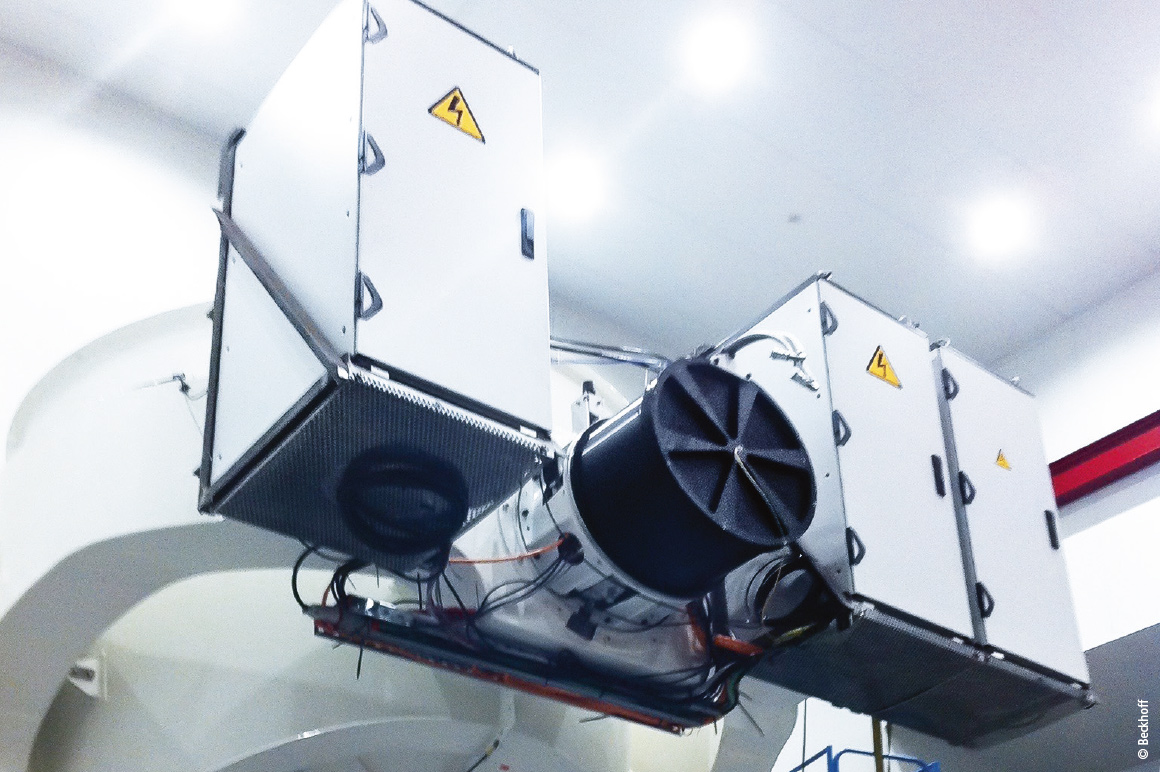

The close cooperation between Beckhoff and GTC extends not only to modernization, but also to the development of new technologies such as instrument calibration modules (ICMs). It is common practice to use an ICM to calibrate scientific instruments. In the GTC, this system consists of a series of lamps with defined wavelengths and a mechanism for positioning a parabolic mirror that reflects the light onto the telescope mirror. PC-based control is used to control and dim the ICM’s spectral and incandescent lamps. A CANopen interface (master) for operation with the existing CANopen infrastructure was also implemented.

This was followed in 2018 by another calibration module: the ICM-FC. TwinSAFE was used in this project to prevent the mirror from moving and to control the intensity of the illumination when people are in the vicinity. Additionally, this ICM is in charge of controlling the power supply for hollow cathode lamps. Beckhoff technology has also played a role in other projects, such as monitoring and controlling the helium tank compressors and their refrigerants.