Linear servomotors and TwinCAT for a high-speed 3D laser machining center

With accelerations up to 12g, micrometer-level precision, and 500 microdrillings per second, Bi.Lab Advanced Engineering in Bologna showcases the cutting-edge capabilities of its laser processing center by synchronizing linear drives with laser pulses. When it comes to automation, the machine builder relies on the flexibility and performance of Beckhoff’s control and drive technology.

Founded in 2002 as a mechanical design office in Casalecchio di Reno near Bologna, Bi.Lab has developed extensive expertise in various fields, including laser technology, assembly automation, robotics, and image processing. Their developments are incorporated into prototypes and customized machines for customers in various industries, including production lines for packaging, textiles, automotive parts, medical technology, printed materials, and food. The secret to their success in so many different sectors also lies in the advanced automation technology provided by Beckhoff. “Looking back, this partnership that began all those years ago was a pivotal moment for our company,” recalls Marco Faretra, partner and managing director at Bi.Lab.

A benchmark for success

To meet growing customer demand for turnkey special machines, Bi.Lab started looking for a standard automation platform. “We’ve always depended on our customers’ resources and implemented automation with their preferred systems,” explains Marco Faretra. Nevertheless, the rising complexity of projects created the need for a single platform that could handle diverse technologies and varying levels of complexity. This led to a benchmarking process to find a strategic partner offering a flexible and high-performance solution for all requirements.

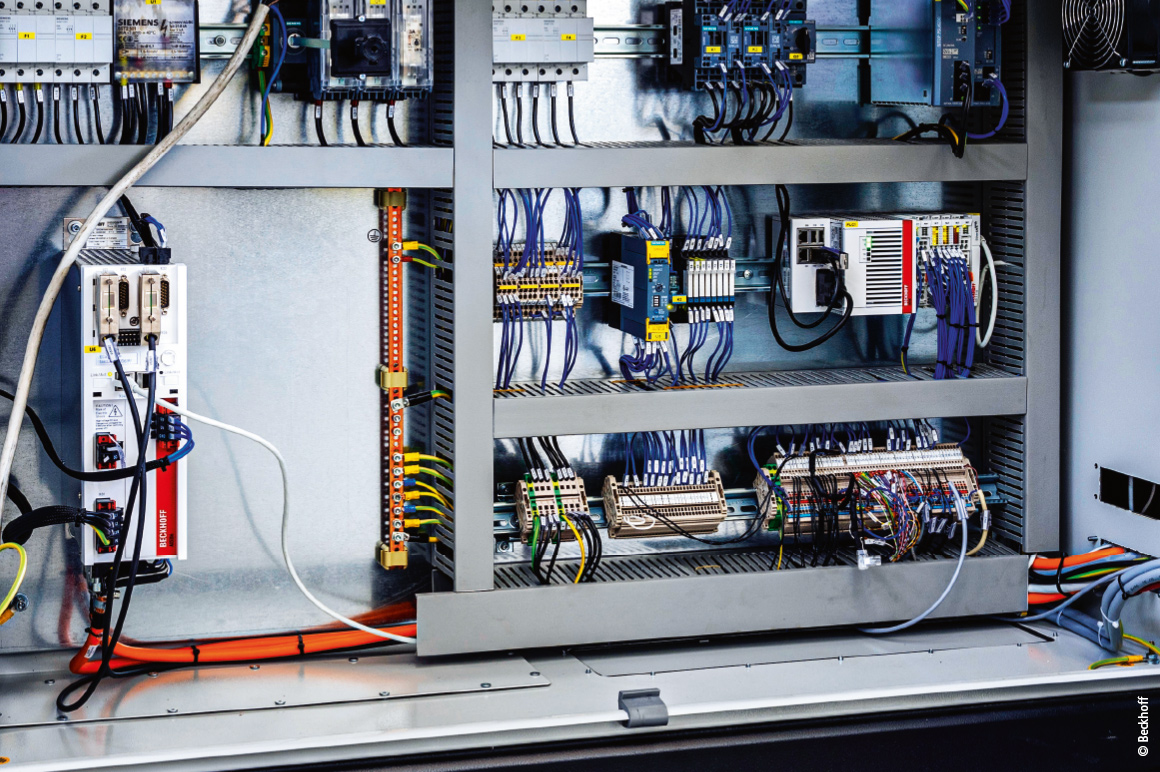

Every automation project at Bi.Lab is now implemented using PC-based control technology from Beckhoff, which provides the flexibility, reliability, and high performance needed to meet specific customer requirements. No matter how different the applications are, they all share the benefits and flexibility of PC-based control technology, combined with the simplicity and power of TwinCAT as an engineering platform. “The modular and comprehensive Beckhoff portfolio also supports seamless integration with third-party hardware and software when requested by customers or required by specific applications. This open system architecture ensures Bi.Lab can always select the ideal components,” explains Lorenzo Bruscoli, automation developer and partner at Bi.Lab.

Highly dynamic cutting and drilling

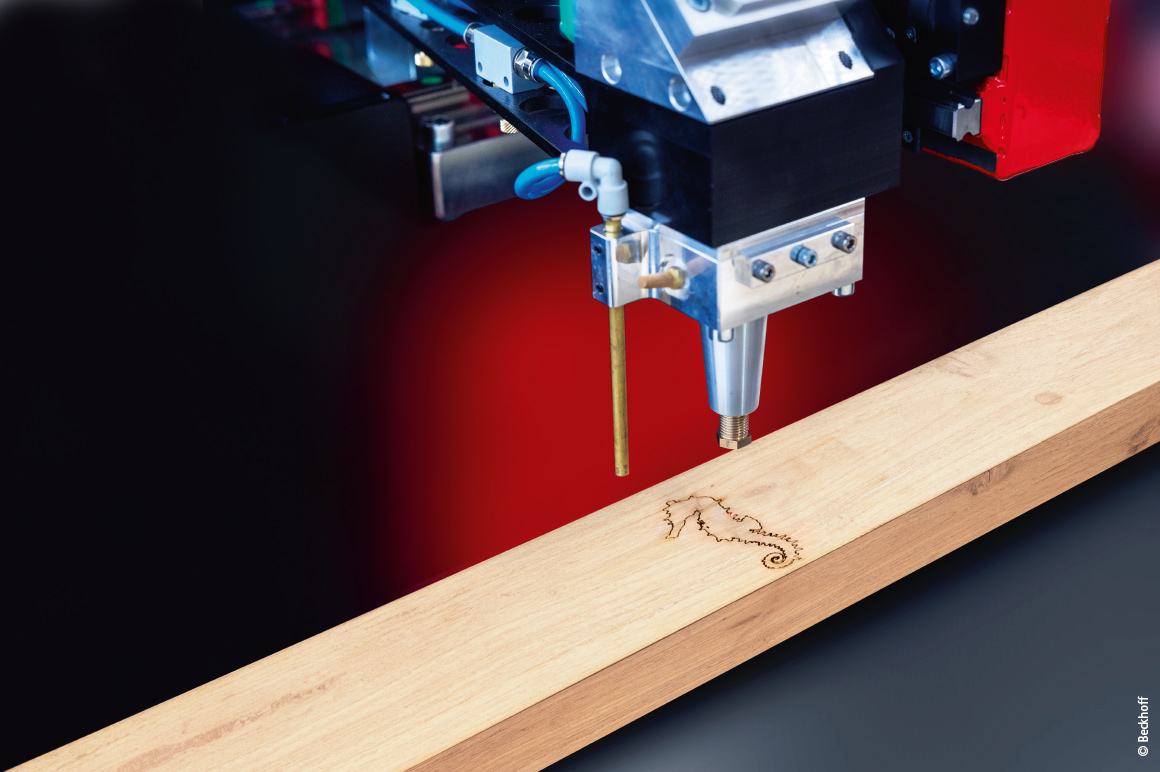

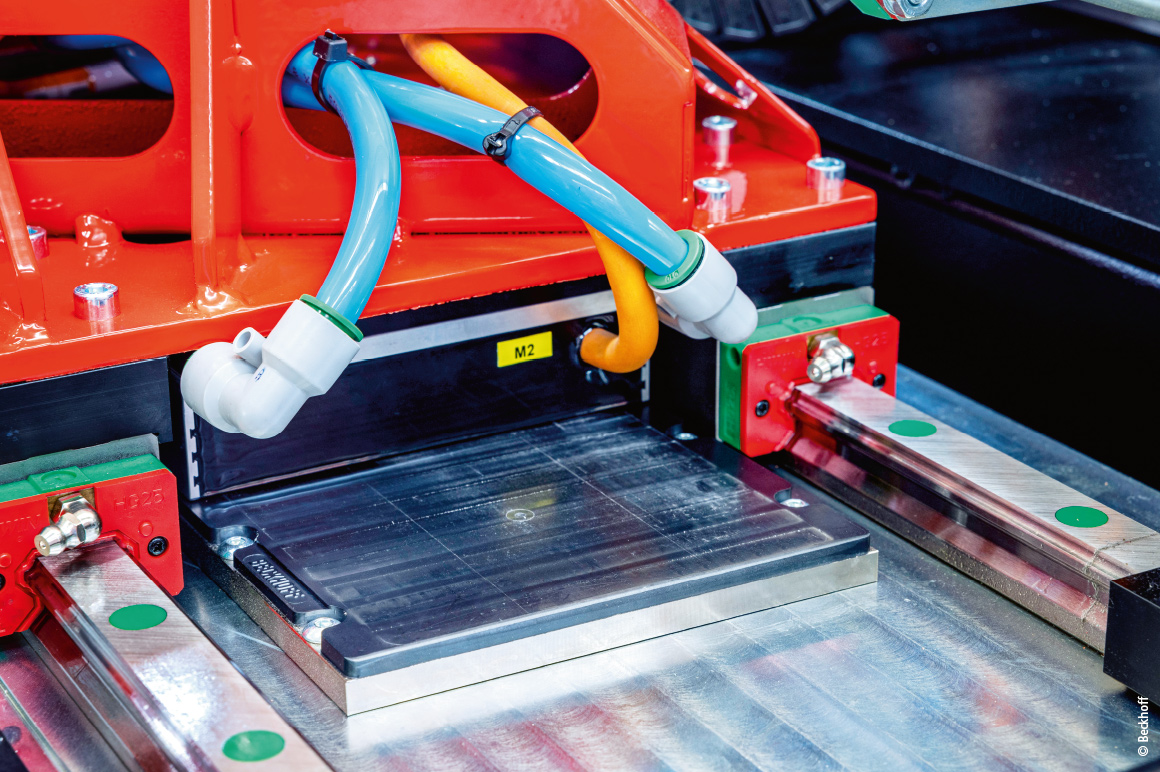

Bi.Lab recently developed one of its most cutting-edge projects to date for a customer in the automotive industry. The challenge was to develop a system for cutting and drilling pipes using a highly dynamic 3D laser processing center. The project required accelerations of over 3g on a cutting surface of 800 x 600 mm, with laser-point positioning accuracy within tolerances of hundredths of a millimeter. With Beckhoff’s automation technology, the first prototype achieved an extraordinary dynamic of 12g on the secondary axis. “This result was also due in part to the support of the Beckhoff product specialists,” explains Marco Faretra. This solution laid the groundwork for a wide variety of subsequent applications. The dynamic nature of the process and the need to increase accuracy to within a few hundredths of a millimeter required an extremely rigid structure. “When developing the frame for the laser processing center, we used virtual prototyping techniques and relied on our experience in highly dynamic system design,” adds Davide Carati, mechanical engineer at Bi.Lab.

Bi.Lab’s experience in research and development, combined with rigorous testing of potential dynamic performance, allowed the company to deliver a fully functional machine to the customer in just two months. This fast turnaround was achieved by leveraging an established automation and control architecture, with PC-based control ensuring the required dynamics and precision. One of the customer’s requirements was to achieve ‘clean’ processing, meaning the pipes had to be processed without leaving any residue inside – even with a large material thickness-to-diameter ratio. This required exceptional precision and repeatability in laser positioning.

The Beckhoff system played a decisive role in meeting the customer’s requirements and delivering the machine on time. At the heart of the controller is a CX5140 Embedded PCpowered by an Intel Atom® quad-core processor (1.91 GHz clock frequency). For the gantry axes, Bi.Lab relies on AL8000 linear servomotors and an AX5206 2-channel servo drive, ensuring the necessary high dynamics and positioning precision. Positioning and path control are handled by the TwinCAT NC PTP and TwinCAT NC I motion software modules, with the latter enabling seamless G-code execution and interpretation. TwinCAT takes care of axis interpolation, efficiently processing kinematic data from both linear motors while also accounting for mass and inertia values. As Lorenzo Bruscoli explains, “This enabled us to calculate the torque and speed setpoints for each axis precisely and transfer them cyclically to the servo drives via EtherCAT.” The entire process, including the safety functions implemented with TwinSAFE components, was programmed with TwinCAT.

Maximum flexibility and precision

The laser processing center showcases the full potential of Beckhoff’s PC-based control, an open control platform that delivers exceptional flexibility, intuitive operation, and seamless integration of third-party hardware and software modules. Thanks to its precise synchronization of drive axes with pulses from the external laser source, the system can create up to 500 microholes per second with pinpoint accuracy in a predefined pattern.