Upscaling a 5-axis CNC machine with TwinCAT CNC

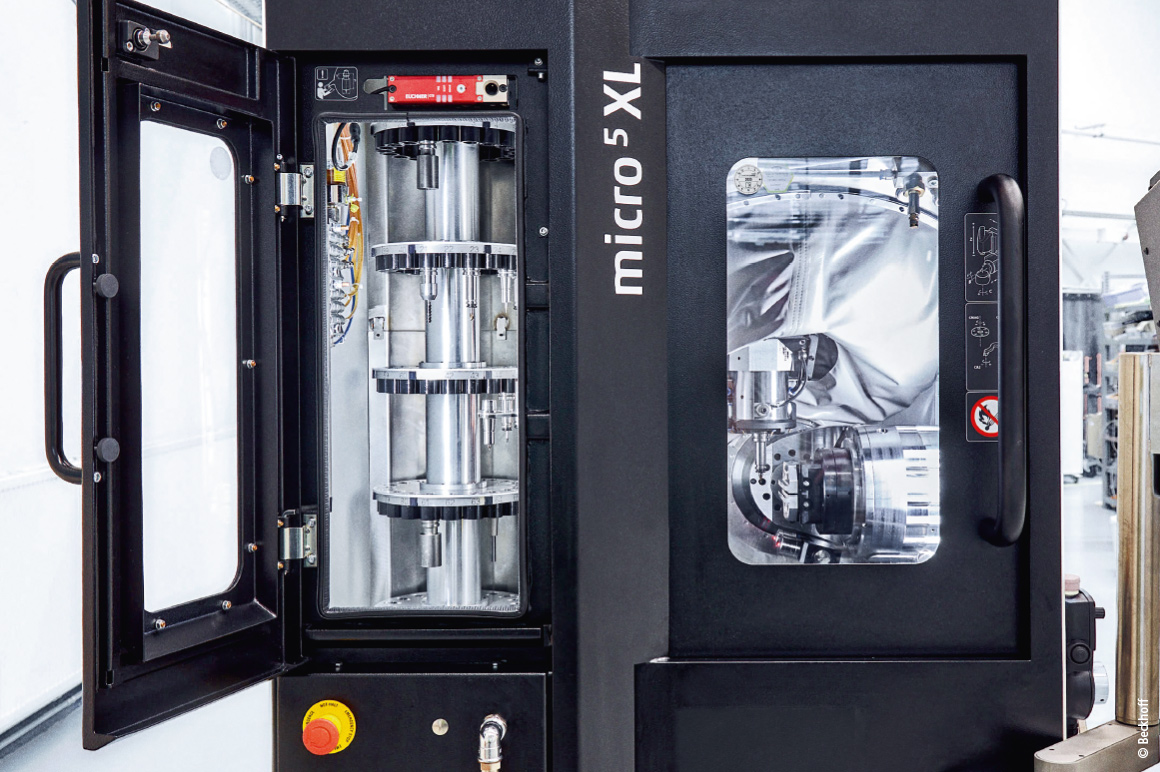

It’s not just the watchmaking industry that needs compact and dynamic machine tools like the Micro5 from Chiron – in medical technology and mold making, components need to be machined just as precisely and quickly. The workpieces, however, are much larger. The machine builder has therefore scaled up its concept based on PC-based control from Beckhoff for components with an edge length of up to 120 mm.

“Market analyses and discussions have shown that there is indeed a need for a highly dynamic 5-axis CNC machine with a larger milling center than the successful Micro5 series offers for components with an edge length of up to 50 mm,” says Matthias Rapp, Vice President Global Marketing at Chiron Group SE in Tuttlingen. Therefore Chiron decided to develop the Micro5 XL building on the existing machine concept, with which Chiron wants to open up further markets that, like in the watchmaking industry, have to produce components with complex geometries and different materials with maximum dynamics, precision, and short cycle times. “Typical target markets for the Micro5 XL include the medical industry and mold making,” says Michael Wurster, Senior Product Manager at Chiron.

The 5 in the series name stands for what Chiron considers to be the optimum 5:1 ratio of milling center to workpiece size. The XL refers to the enlarged axis structure from 250 mm to 600 mm and the workpiece size of up to 120 mm edge length. “Added to this are higher cutting performance and maximum flexibility,” says Mathias Rapp. This is ensured by the tower magazine for up to 100 tools and the optional handling system for loading and unloading. With PC-based control as an open control platform from Beckhoff, the expansions can be mapped in a modular manner in software and hardware.

Simple upscaling with a flexible modular drive system

In principle, machine concepts cannot be scaled arbitrarily: At some point the ratio between the moving masses of the workpiece and tool sides diverges. “With the Micro5, we’re talking about a moving mass of 10 kg on the tool and workpiece side; with the Micro5 XL, it’s up to 80 kg,” says Michael Wurster, explaining the challenge of the development project. Nevertheless, Chiron was able to significantly increase the machining area and workpiece size with PC-based control while maintaining the specifications – small footprint and energy requirements with high rigidity and dynamics. “In terms of resource efficiency, we have achieved the optimum with the Micro5 XL, without compromising on precision and speed,” says Matthias Rapp with satisfaction.

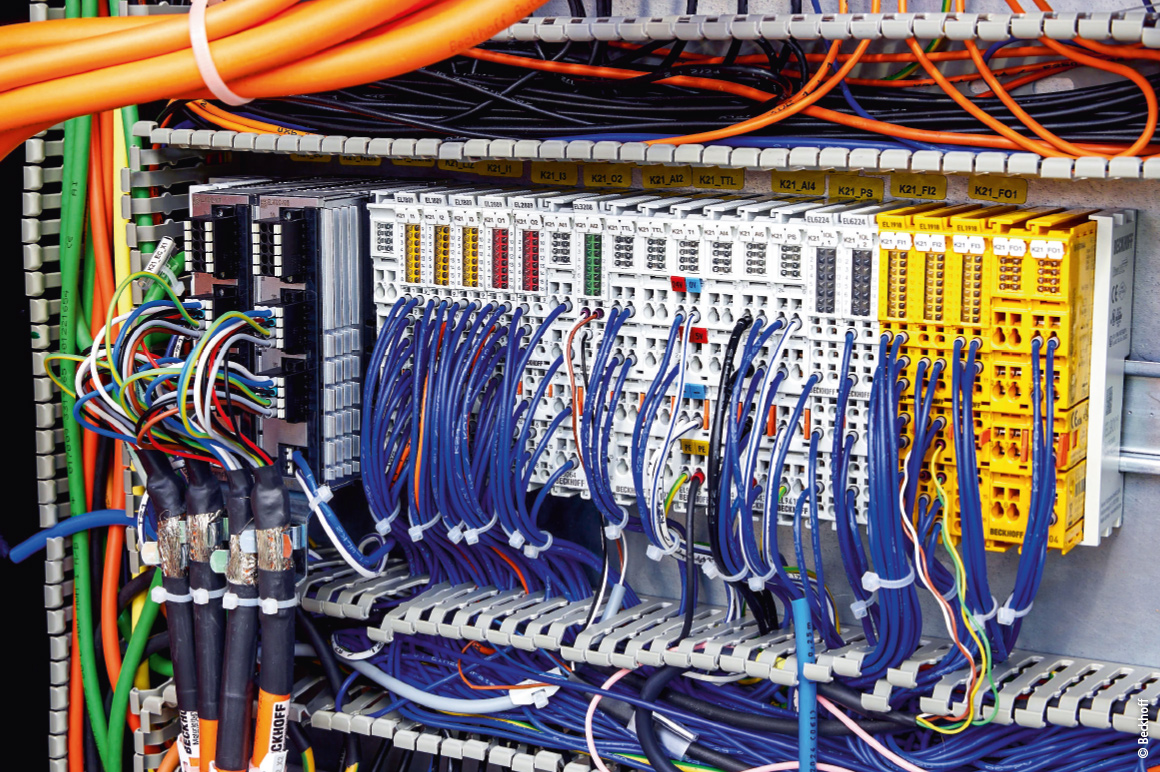

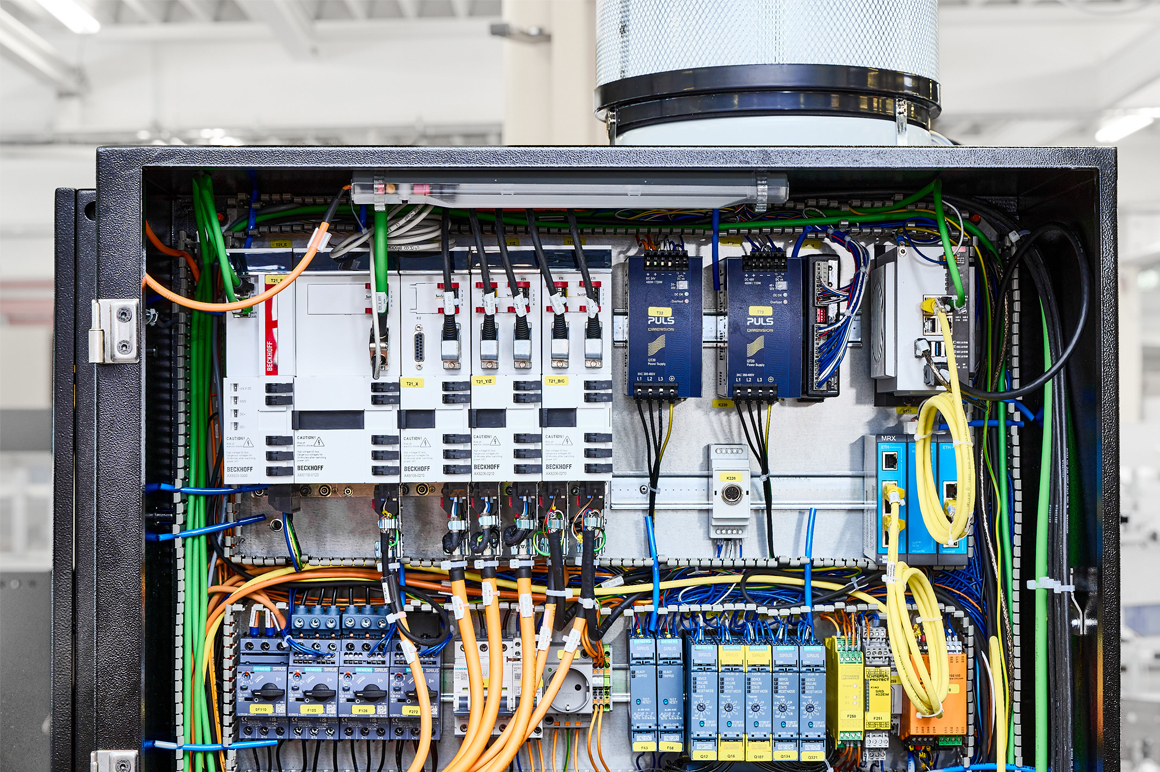

The wide range of drive components, such as the AX8000 multi-axis servo system, the AM8000 synchronous servomotors, and the compact drive technology in the EtherCAT I/O system, support and facilitate the scaling process. The tower magazine, for example, was implemented with AM8100 servomotors and ELM7212 servomotor EtherCAT Terminals. “These servomotors and EtherCAT Terminals for the low-voltage range up to 48 V DC offer high performance in a very compact design,” explains Dieter Völkle. Integrated directly in the EtherCAT terminal segment, they can be used dynamically in the CNC channel or as a PTP axis and synchronized with the other axes.

Small footprint through compact control technology

With a footprint of just 1.7 m² for the complete machine tool including peripherals (coolant system and chip management), space for the control technology is tight. Chiron gains valuable space with One Cable Technology (OCT) as its connection technology, among other things. Michael Wurster comments: “Together with the AX8000 multi-axis servo system and the servomotor EtherCAT Terminals, this has simplified the compact set-up and also saved time during installation.” And if a motor cable ever needs to be replaced, OCT makes this much quicker than laying two separate cables for the motor and feedback system.

As the Micro XL was developed with great attention to balanced mass ratios, the upscaling had no negative effects on the control behavior. “We were able to use the TwinCAT 3 Motion Designer project planning tools to design the drive axes and controllers, and received excellent support from the Beckhoff experts for fine-tuning based on the Bode diagrams and the load spectra we specified,” confirms Michael Wurster.

Faster, more precise, and a finer finish

In the end, Chiron was able to achieve further improvements in machining with the Micro5 XL in terms of cycle times, surface quality, and dimensional accuracy compared to standard machines on the market for machining this component cubature. “This is partly due to the even mass distribution between the tool and the workpiece side and, of course, also to precise control with TwinCAT 3 CNC,” says Matthias Rapp. Dieter Völkle outlines another important aspect for series machine manufacturers such as Chiron: “In the long term, it is an advantage not to need any special solutions and to be able to implement everything with standard components.”

Chiron uses a C6030 ultra-compact Industrial PC as the control platform for the 5-axis CNC machine, on which TwinCAT 3 CNC (TC1270) with numerous technical functions such as TwinCAT 3 CNC Spline Interpolation (TF5260), CNC Channel Pack (TF5230), CNC High-Speed-Cutting (TF5250), CNC Axes Pack (TS5220), and CNC Transformation (TF5240) are installed. The movements of the five axes and the screw are interpolated and synchronized via one channel of the software CNC; the servo drives of the tool changer are synchronized via the second channel. The user interface of the Micro5 XL is based on TwinCAT 3 HMI (TF2000) and the CNC visualization for machine tools programmed in C#. “We keep hearing from customers how easy it is to use our machine tools with TwinCAT HMI from Beckhoff,” says Matthias Rapp. “A Swiss watch designer taught herself how to program and mills her designs herself using a Micro5.”

Documenting efficient production

Chiron uses TwinCAT 3 Analytics Logger (TF3500) to control the machining process. “We want to use the drive currents to determine the cutting forces and thus protect the screw from overload,” says Michael Wurster. In addition, a vibration sensor monitors the machine tool. Chiron records the current consumption via an EL34xx EtherCAT power measurement terminal and displays the current energy requirement to the operator in the visualization. “Compared to other machines on which similar parts are manufactured, we achieve energy savings of around 50% and can also prove this with the energy measurement solution from Beckhoff,” says Matthias Rapp, highlighting an important aspect. If users want to calculate the carbon footprint of their products, they can assign the consumption values to a specific production batch. As various industrialized countries promote efficiency measures in production, this function can be decisive for customer wins. Many companies have also set up their own efficiency programs that go beyond the legal requirements and require suppliers to provide information on energy consumption or carbon emission per component. “With the power measurement technology from Beckhoff, this can be easily implemented and transferred to energy management systems or MES via OPC UA,” says Dieter Völkle.

Chiron has a wide range of different machine tools and machining centers in its portfolio. “We will be looking step by step at the various options that PC-based control from Beckhoff opens up for us,” adds Matthias Rapp.