EtherCAT-based control technology for transporting gigantic tunnel elements

The 18-km long Fehmarnbelt tunnel between Rødbyhavn on Lolland in Denmark and Puttgarden on the German island of Fehmarn will be the world’s longest immersed tunnel by 2029. To this end, 79 standard tunnel elements with a length of around 220 m and a further ten special elements are being manufactured on a 150-hectare construction site near Rødbyhavn. Swiss companies Hebetec Engineering AG and Elpex AG are automating and controlling the safe transport of the elements, which weigh over 73,000 tons, using EtherCAT terminals and PC-based control technology from Beckhoff.

The Fehmarnbelt tunnel is being built using the same technology that was used for the Øresund connection between Denmark and Sweden: immersed tunnels. The tunnel requires 79 standard and 10 special elements for installing the tunnel infrastructure. To start an element, reinforcing steel is connected to form a cage and pushed into prepared formwork. Concrete pouring then begins in the casting hall. Once the concrete has hardened sufficiently, the formwork is partially removed and the first 24-m long segment is moved to make room for the next reinforcement cage.

This process is repeated until all nine segments of a tunnel element have been concreted and successively pushed out of the hall into the dry dock. There, the 217-m long tunnel elements are sealed with bulkheads. Despite weighing around 73,500 tons, the components float when the dock is flooded and can be pulled into the harbor basin. In order to meet the tight schedule for completion in 2029, the standard elements are being concreted on five parallel lines.

Moving gigantic masses precisely and quickly

Throughout the entire process, the huge tunnel segments are leveled on hydraulic supports and pushed several hundred meters using hydraulic rams. The concept was developed by Swiss company Hebetec AG in Hindelbank and automated in collaboration with Beckhoff Solution Provider Elpex AG in Kirchberg. “Moving the 43-m wide elements, which were over 200 m long in the end, safely and precisely from the concrete hall to the basin was a real challenge,” emphasizes Olivier Briguet, Head of Operations at Hebetec. Each line is fed by six double hydraulic cylinders with a stroke of 1.8 m, which are mounted on a movable frame that is pressed against the side of the skidding beams by means of jaws. The six rams press the segments evenly forward, then release their clamping, retract, and are pulled forward in the process. Then the process starts all over again.

“The skidding beams are around 400 m long and of course not perfectly straight,” Olivier Briguet points out a further complication. To avoid stresses in the concrete, the segments are continuously leveled using dozens of lifting cylinders. For the leveling of one segment alone, 36 presses – divided into three hydraulic groups – have to be controlled. This compensates for the tolerance of +/-5 mm and minimizes friction due to the smaller contact surface. “The force required for pushing is significantly lower at 1.2% of the hydraulic power than the initially calculated 5%. This saves Femern Link Contractors, the manufacturer of the tunnel elements, a lot of energy costs,” says Urs Krähenbühl, deputy managing director at Elpex.

Furthermore, the weight of the segments is not homogeneous. This must be taken into account when pushing to prevent the tunnel elements from tilting – as must the different friction on the lifting cylinders. The tunnel segment will only stay on track if all pushers (presses) push with the same force. “To do this, we use pressure sensors on each leveling ram to record the weight and use TwinCAT to control the pressing force of the pushers via the speed of the hydraulic pumps,” explains Benjamin Schwab, software team leader at Elpex. In addition, the operator riding along on the segment in the control cabin can intervene and individually adjust the pressure of individual feed cylinders via an overflow valve. To assist the operator, there is a guidance system that detects and displays the direction. At the end of the construction hall, the 43-m wide segments have to pass through a relatively narrow gate in as straight an orientation as possible.

Control and monitoring station are riding along

The project involves the use of a large number of presses with a force of 240 to 390 tons and hydraulic accumulators to meet the operator’s requirements for continuous production of the segments at a rate of 10 m/h. Feed, leveling, and direction are monitored and controlled by the operator using a CP2924 multi-touch Control Panel. The control station is located in a small container, which is placed on the tunnel segment together with the accumulators and moved along with it.

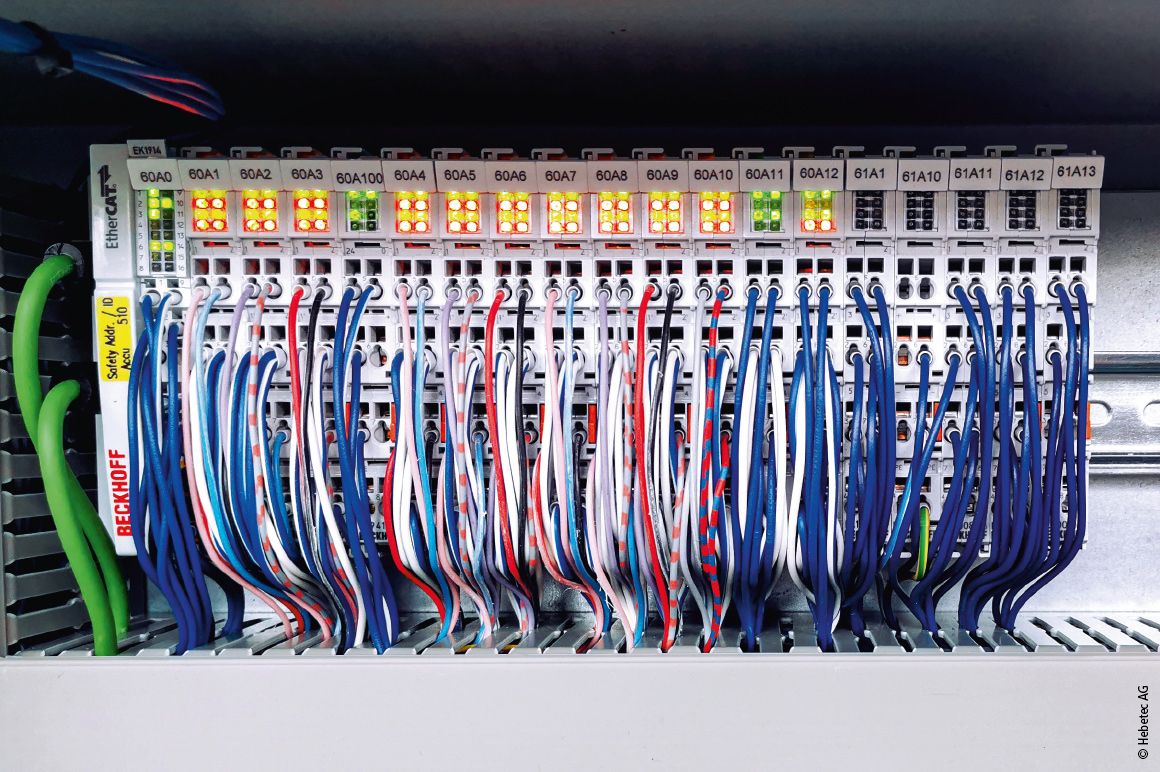

In line with the size of the project, the quantity structure of the control technology is also extremely extensive: Distributed across a large number of control cabinets with a total connected load of 820 kW, a large number of analog EtherCAT Terminals (EL3024) and digital input/output terminals are installed for recording all signals and precisely controlling the motors and hydraulic valves. There is also a wide range of power supply terminals and EK1914 EtherCAT Couplers with integrated standard and safety I/Os as well as EL6910 EtherCAT Terminals with TwinSAFE Logic. C6030 ultra-compact Industrial PCs are used for control purposes. “As a rough estimate, we laid around 4.5 km of cable for the power supply, 3.5 km of EtherCAT cables, and 67 km of control cables,” says Urs Krähenbühl, outlining the scope of the project. “The flexible topology selection options offered by EtherCAT were a great help when it came to cabling,” adds Benjamin Schwab, software team leader at Elpex. This allowed the accumulators distributed across the tunnel segments to be connected in line, while the pushers on a production line were connected using a CU1128 8-port EtherCAT junction in a star topology.

Flexibility provided by EtherCAT and hot connect

“We have laid everything out twice for each production line because we have to start on the next tunnel element while the other one is still leaving the hall,” says Olivier Briguet. It must also be possible to replace defective components quickly and easily. “The EtherCAT hot connect function gives Hebetec and Elpex the flexibility they need,” confirms Andreas Iseli, head of the Beckhoff office in Lyssach. To this end, Elpex configured the many different combinations of cylinders and accumulators. This enables the fitters to take the required components from the warehouse to start a new segment or in the event of a defect, mount them on the line and connect them using connectors.

Safety project implemented with EAP and cross traffic

“Given that devices aren’t permanently installed and can be connected in almost any combination, we also needed a universal solution for the safety application,” says Benjamin Schwab, pointing out a special feature: A typical safety control always requires clearly specified configurations. In this project, the safety control must automatically detect the respective combination of devices during startup and compare it with the configuration set on the HMI. “With hot connect, we were able to achieve this flexibility in the safety section as well,” says Benjamin Schwab. However, due to the large number of device combinations, more TwinSAFE groups had to be configured than those supported by an EL6910 EtherCAT Terminal. Elpex was able to implement this easily with a second EL6910, which communicates with the other TwinSAFE Terminal via the EtherCAT Automation Protocol (EAP). “Hans Baumberger, application engineer at Beckhoff, provided us with a great deal of support during the implementation of cross-communication,” recalls Benjamin Schwab.

Despite the extensive quantity structure, Elpex only needed 1,800 hours for engineering and programming with TwinCAT. EtherCAT was also very helpful in configuring, testing, and commissioning the extremely large number of hydraulic valves and other components, enabling the plant to be commissioned in around 300 hours. “PC-based control and Beckhoff were the perfect technology and the ideal partner for this unique project,” concludes Urs Krähenbühl.