XPlanar boosts productivity in medical device assembly

The specialists at Automation NTH managed to reduce the space requirement of an assembly machine for medical diagnostic devices by a factor of 10. In addition, the throughput accelerated from 5 min to 5 s per device. The intelligent transport system XPlanar from Beckhoff provided the basis for the innovative system concept. With floating movers it enables entirely free product transport and handling with up to six degrees of freedom.

Automation NTH, founded in 1999 and headquartered in LaVergne, Tennessee, started as a systems integrator and became a specialized solution provider for life sciences applications. “Most custom automation equipment, especially in medical device assembly, has a high emphasis on software,” says Peter Sarvey, Head of Sales at Automation NTH. That’s why the life sciences specialists like to deploy new technologies to automate the often highly complex and data-intensive applications.

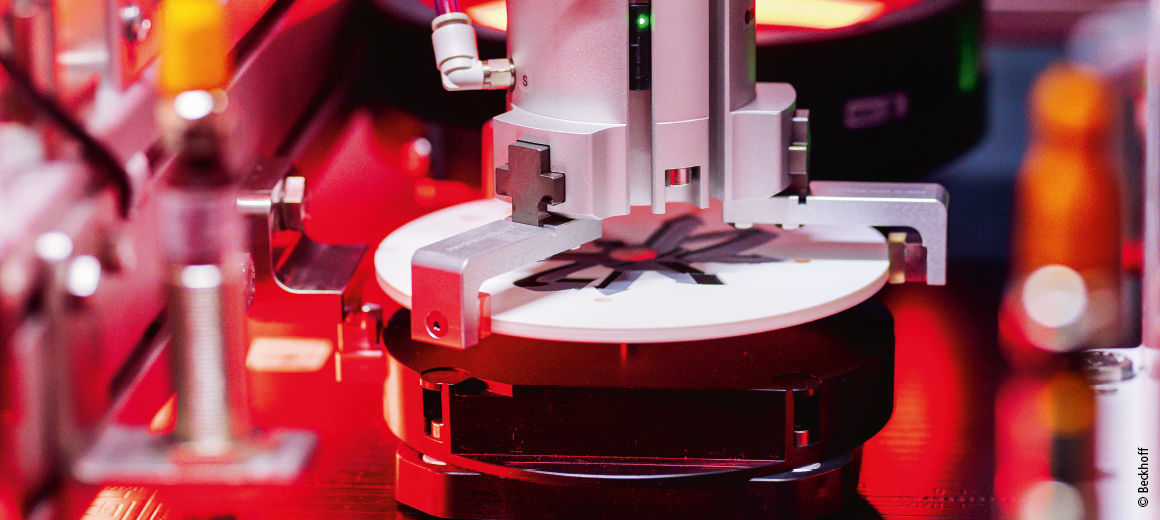

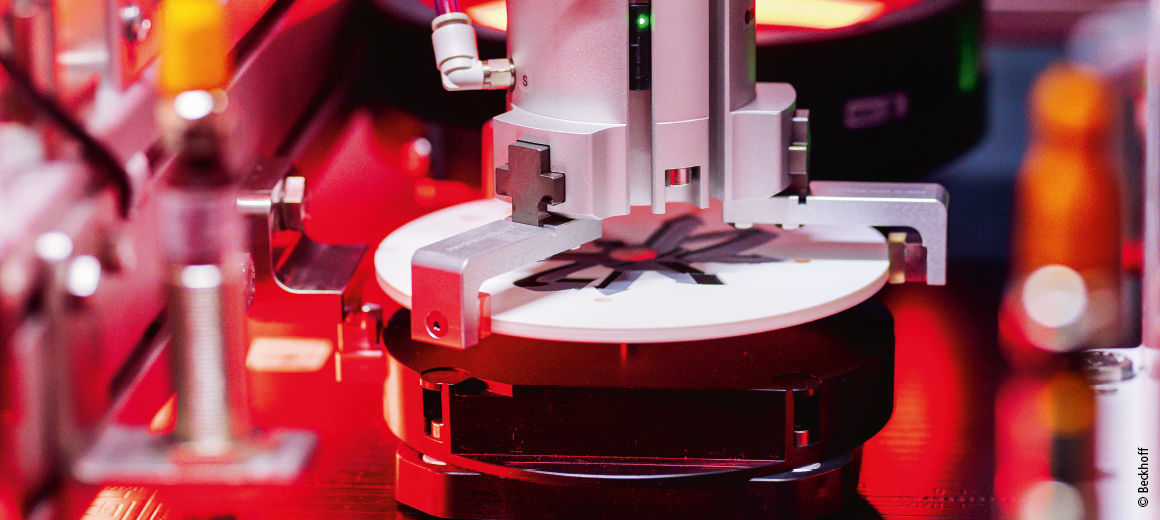

Case in point: an innovative Diagnostics Device Assembly Machine that leverages the XPlanar adaptive transport system from Beckhoff. The electrically passive XPlanar movers, which levitate above electrically active motor modules, provide six degrees of freedom in motion control with extremely high precision and repeatability. According to Automation NTH, this enabled excellent traceability, a compact footprint in costly cleanrooms and maximum product integrity when dosing sensitive reagents.

“We selected XPlanar due to its flexibility to transport numerous products with high variability and accommodate all kinds of future changes,” explains Automation NTH Project Manager Rich Snodgrass.

From manual to automated assembly

To define the scope of automation requirements for the previously manual assembly process, representatives of a startup company met with Automation NTH Director of Strategic Accounts Molly Blazek and Head of Sales Peter Sarvey in 2023. The customer needed an automated system with fillers for roughly 50 different reagents, supporting dispense locations that change for the three different device types.

“Moving the dispense heads to the product – with conveyors, robotics or other material handling technologies – would create massive price and space requirements,” Peter Sarvey says. “Then we realized we should move the product, not the dispense heads.”

The equipment would operate in a cleanroom, with square footage at a premium due to the necessary environmental controls for temperature and humidity. So the system needed to be as compact as possible while being able to support future product changes. Traditional dial tables and linear transport systems didn’t check any of the boxes, according to Molly Blazek.

Automation NTH Sr. Controls Engineer Joseph Cocchini began evaluating options. After testing a competitive product, Cocchini ran through the same requirements with Todd Thollot, Advanced Applications Group Manager at Beckhoff USA. “I had a list of lofty goals. We needed to dynamically coordinate the XPlanar movers to use a spring-loaded hook to hold and then release product, park movers on the motor tiles to unload, and ensure the lift, tilt, 360-degree rotation and other capabilities matched the advertised specs,” Joseph Cocchini says.

“Todd had already programmed in several scenarios that validated most requirements right away. Beyond that, the levitation height was better with XPlanar than with the previously tested system, so the movers could tilt more,” he adds. “Overall, Todd’s implementation was much cleaner because the Beckhoff system allows you to access every motion aspect of each individual mover, right down to the ABC and XYZ coordinates. That nearly infinite configurability is why we ended up going with XPlanar.”

Adaptive automation via flying motion

In the finalized Diagnostics Device Assembly Machine, operators manually infeed specific devices via a drawer. Then a robot places the device on one of the 18 XPlanar movers. Custom tooling locks the device in place on the mover. Then the device undergoes a vision inspection using 360-degree rotation.

The movers fly the devices through a variety of dispense stations lining the 18-motor-tile work surface. The hovering movers stop only at the dispense stations specified in each device’s recipe, with a second vision test halfway through. For filling, XPlanar mover rotates the device so the reagent is placed in the correct location for that formulation.

After a final vision inspection, the device is positioned at a reel feeder, which seals it with an adhesive plastic cap with +/-30 µm repeatability. The mover then delivers the finished product to an operator station. The mover slides the release hook into a groove, edges forward to release the device, and then parks with power off on the tile below so that it no longer levitates. An operator can then reach in safely through the light curtain to remove the finished device.

Powerful software and hardware

TwinCAT provided an end-to-end engineering and runtime platform for automation. Integrated into Microsoft Visual Studio®, TwinCAT empowers engineers to program in the languages that best fit the application. In addition, the software includes a graphical configurator for XPlanar that helps with creating motor tile layouts, adding movers via simple drag-and-drop, defining paths and stations, and simulating motion profiles.

On the hardware side, a C6670 control cabinet industrial server from Beckhoff supports the control of XPlanar and third-party devices. This 40-core Industrial PC (IPC) possesses ample computing power with some cores reserved for future needs. What impressed Joseph Cocchini even more is the C6017 ultra-compact IPC that powers the four-axis reel feeder system.

“The C6017 has 8 GB DDR4 RAM, a 320 GB hard drive, four Ethernet ports, and four USB ports,” Cocchini explains. “That little Windows 10 computer drives our smartphone-sized HMI with a custom Solid JavaScript, as well as a Python Web server and a MongoDB database for OEE, recipes, configs and more. I haven’t seen anything like it in my career.”

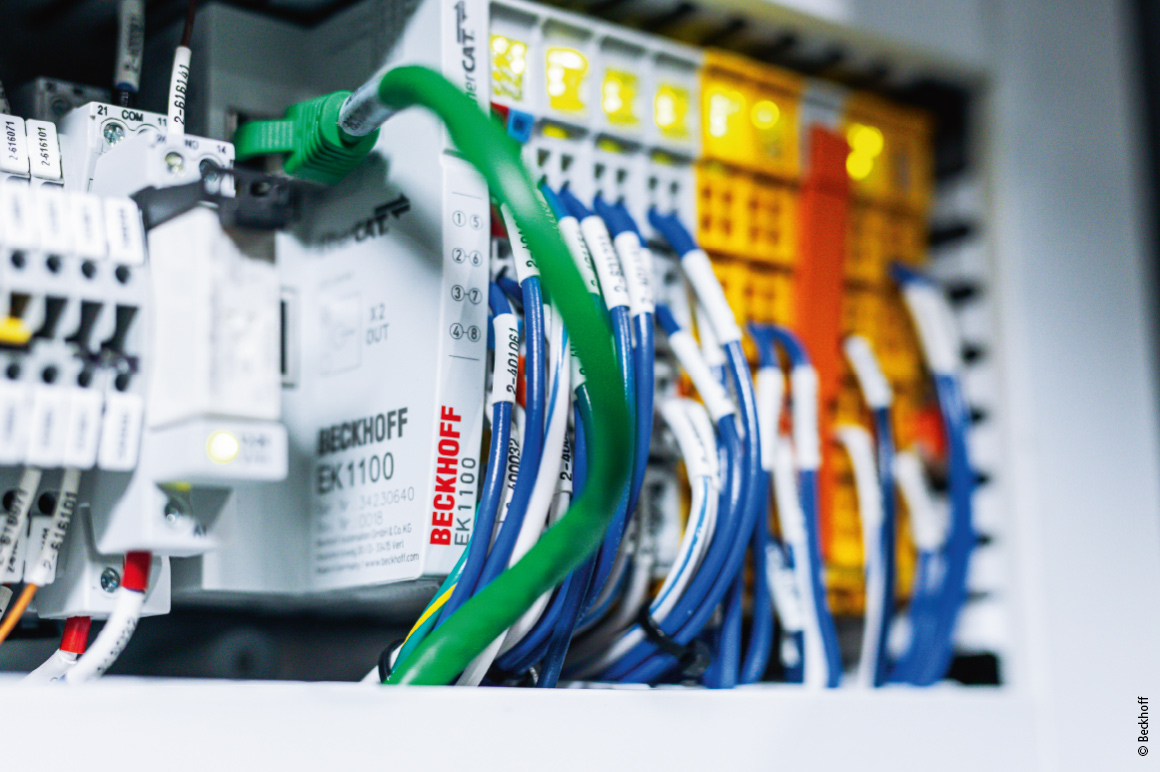

Fast real-time communication and exact synchronization with EtherCAT is crucial for the precise control of the XPlanar system. Enabling communication with the various cameras, dispense heads and other devices via EtherNet/IP was possible by the simple addition of the appropriate bus coupler. All safety-relevant data are transmitted via Safety over EtherCAT (FSoE) to the TwinSAFE terminals installed in the standard I/O segment for evaluation with the necessary safety logic. So, if an e-stop or light curtain is triggered, the system will enter a safe state without any need for hardwiring. Along with numerous EtherCAT Terminals for standard signals, Automation NTH also uses I/O modules from Beckhoff for overcurrent protection and other functionality.

New assembly concept for medical devices

The completed Diagnostics Device Assembly Machine offered the solution for automating the end user’s inefficient manufacturing process. In addition, the system reduced footprint by a factor of 10 compared to what a traditional linear approach would require. According to Automation NTH, XPlanar also reduced power supply requirements compared to competitive solutions, which reduced heat concerns and cooling requirements.

“The reagents are very sensitive to humidity, temperature and movement, so the smoothness of XPlanar’s contactless motion and the cooling option Beckhoff offers all played into the compatibility with the customer’s product,” Molly Blazek concludes.