ATRO: Automation Technology for Robotics

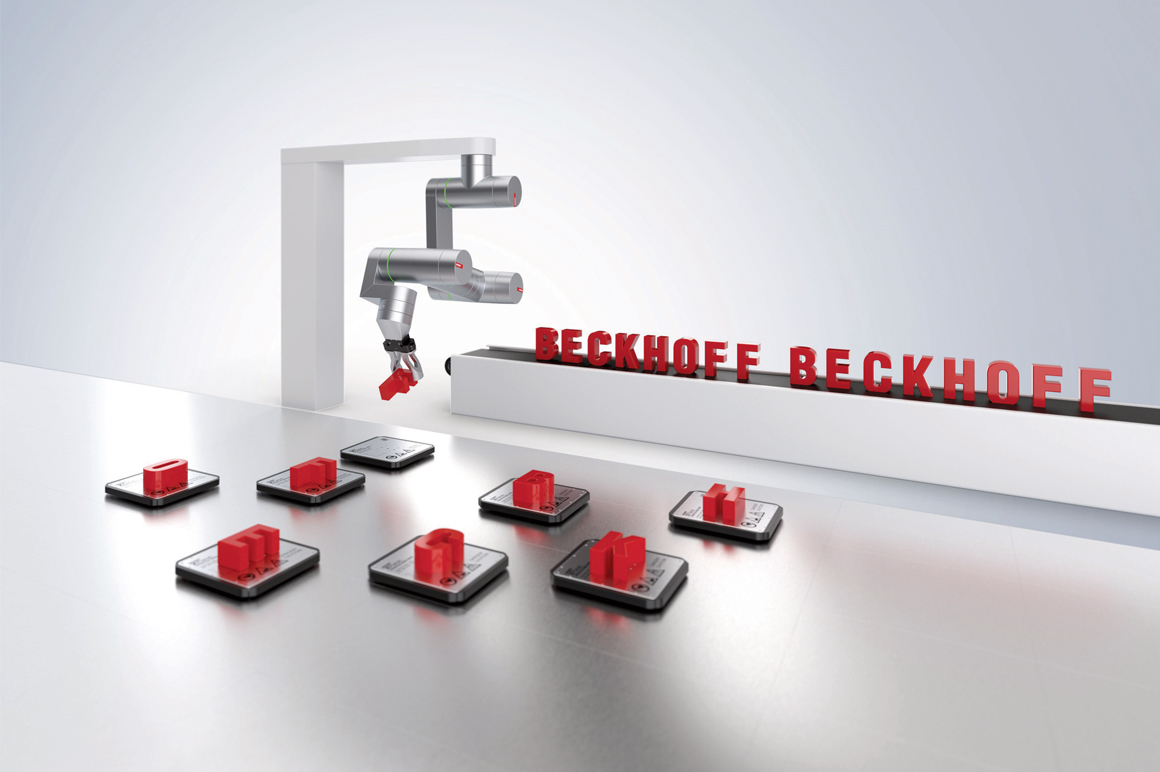

Can you imagine having the right robot ready on the shelf for every handling task around your machine? A small machine type might require a robot with a short reach to insert new, relatively heavy parts. In another type of machine, you might want to stack the finished products on a pallet – this time requiring a large reach. Yet another machine involves a simple, fast pick-and-place application from a fixed infeed to a moving conveyor belt. You are unlikely to always have the right robot to hand for all of these variants. But if a customized robot can be freely assembled from existing standard modules for each task – as with the modular ATRO system from Beckhoff – you can achieve the necessary flexibility without a great deal of effort.

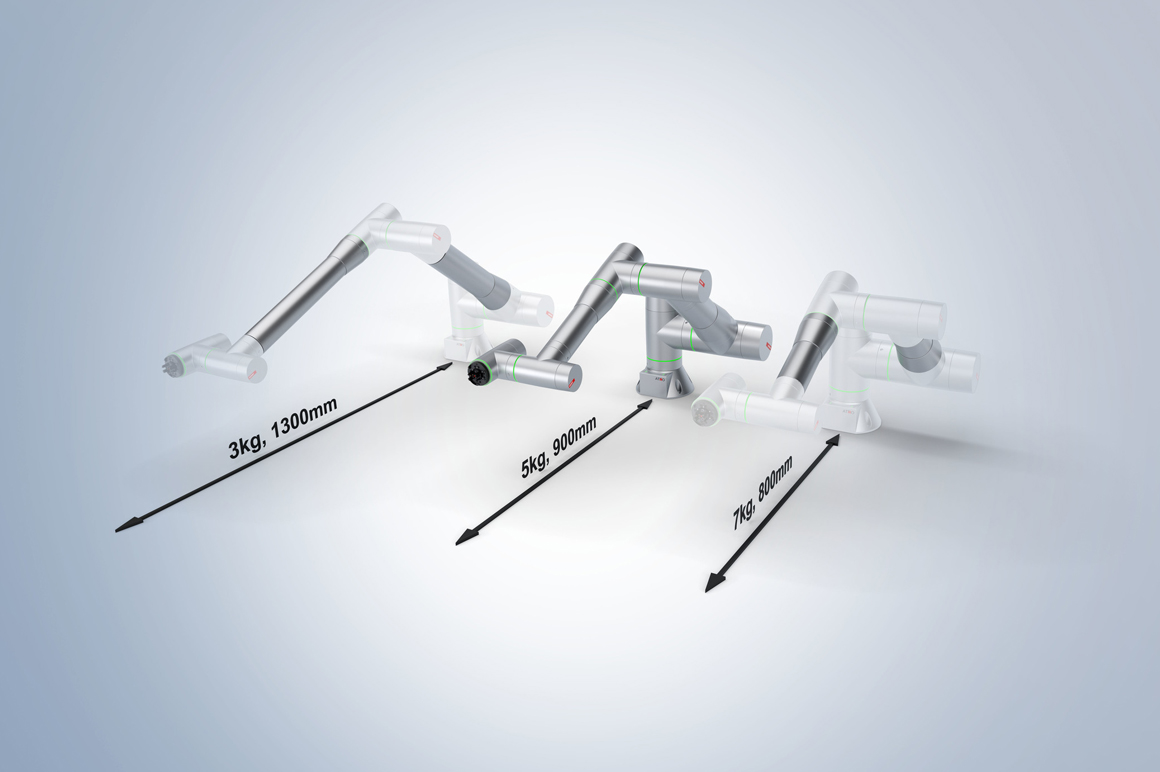

The modularity of the ATRO system from Beckhoff therefore results in concrete advantages for the user. After all, a 6-axis articulated robot is not always the right tool for the job. In many pick-and-place scenarios, just three or four degrees of freedom are enough, which means fewer axes, lower costs, and reduced weight – and these weight savings can then be used to offset a higher payload. The same ATRO motor and link modules can be used to create a wide variety of kinematic designs, which reduces variance in the inventory and increases flexibility.

High flexibility through modularity

The ATRO system is a modular industrial robot system that can be used to put together optimized robot structures for different applications in the field of assembly and handling technology on an individual and flexible basis. Standardized motor modules with integrated drive functionality, together with link modules in various designs and lengths, allow for virtually limitless mechanical combinations. Furthermore, complete integration into the holistic TwinCAT control platform offers direct access to a wide range of proven automation functions. An integrated PC-based platform for machine control, robot control, safety, vision, condition monitoring, or connection to an edge device or cloud system integrates all functions.

Wouldn’t it also be helpful if the external supply lines to the end effector could be omitted? This would mean that they would not be constantly in the way and would also eliminate the need to replace them regularly due to the torsional stress. And without these cables, endless rotation of all the robot’s axes would be a possibility. All ATRO modules offer an internal media feed for data and electrical supply plus two fluid channels for this very purpose. The desired media can be fed in at the base of the robot and are conveyed through the motor and link modules to the end effector. The active motor modules were designed in such a way that endless rotation of all axes remains possible.

ATRO combines modularity and flexibility in an industrial robot system with an internal media feed and endless rotation in all axes, and is integrated into the PC-based machine control system. The ability to (re)use identical module types across various configurations helps cut storage costs and reduces the need for spare parts.

General requirements and properties

A robot is regarded as partly completed machinery as it cannot usually fulfill a specific function without additional components such as tools, sensors, or safety devices. Only when a robot is installed in a machine and equipped with the necessary components does it become a complete machine. In compliance with the European Machinery Regulation EU 2023/1230, which also applies to partly completed machinery, the health and safety requirements must be guaranteed by the manufacturer. The European harmonized standards DIN EN ISO 10218-1 and DIN EN ISO 10218-2 apply to the safety of industrial robots. New versions of these standards were published in early 2025 and will soon take effect once harmonization is complete. As of the end of the transition period (expected in 2027), they will apply to all industrial robots that are new on the market.

If a machine builder puts together their desired robot configuration using ATRO modules and integrates this system into their machine, they must meet the requirements of ISO 10218-2 for the robotic portion of the application. In addition to the hardware modules for the kinematics, the ATRO system also offers software modules that – in combination with pre-tested safety templates – meet precisely these requirements.

Versatile and easy-to-install mechanical system

Each ATRO motor module represents a complete drive system for one axis or joint of the robot. The system comprises a decentralized 48 V EtherCAT drive with brake, gearbox, and Safe Motion functions. This means that the only external components required are a power supply and a control system, which significantly reduces the space required in the control cabinet.

In addition to the active motor modules, there are mechanically passive modules which can be used to create the design of the robot configuration. The modules are assembled by simply screwing them together, whereby the ATRO interface provides a robust mechanical connection and also connects the internal media feed. This means that assembly can be carried out by a single person and individual modules can be exchanged effortlessly, e.g., for maintenance purposes.

The base modules allow the robot to be mounted on a base plate, a wall, or the ceiling. The connection to the internal media feed can be implemented at the side or at the bottom. The tried-and-tested hybrid connectors, which provide both electrical power and EtherCAT or Ethernet communication, allow simple plug-in connection. The robot’s 48 V supply is stabilized in the base by a brake chopper with resistor.

The link modules are offered in different shapes and lengths to form the “arms” of the robot. Since they, like all ATRO modules, are EtherCAT devices and come with their mechanical properties as an electronic type plate, the chosen configuration can be scanned by the controller in order to select the correct calculation rule for motion control.

The ATRO interface also serves as an interface to the tool on the end effector. For adaptation to grippers with an ISO interface, a flange module is offered that routes the internal media to pluggable contacts. A flange set with ATRO interface is available for manufacturers who wish to fully integrate their tools.

Machine and robot control become one

One of the main tasks in integrating robots into a machine or system has so far been to successfully manage the interfaces between the systems: The robot controller must be connected to the machine control system, and both require further automation functions such as vision or coordinated motion functions. For highly dynamic applications, the integration of these systems must be based on real-time-capable interfaces. The movement of the machine axes can then be coordinated with the tool at the robot end effector and synchronized with the detection of the product from the camera.

The TwinCAT automation platform combines all these functions in a PC-based control system. This means that up-to-date information from all functions is available to every device at the same time for processing. This also incorporates information and states regarding the functional safety of the system and the robot, which until now has often been coupled to the system via safe I/O signals.

The robotics integration in TwinCAT includes the configuration of the modular kinematics on the one hand and the motion control programming functions on the other. A 3D visualization tool supports the configuration of the modular kinematics. Here, all types of ATRO modules can be selected to form the desired combination. By importing STEP files, the embedding of the robot in the machine environment can also be visualized. The configuration can then be loaded into the TwinCAT development environment. At the same time, all necessary preparations and links are automatically created in the TwinCAT system so the user can start programming motion control directly.

If there is an online connection to the real controller, the 3D representation can also be used as a live view of the current robot pose and movement or as a simulation view.

An extensive robotics library is available to facilitate programming. The library abstracts the individual modules into a robot instance on which the necessary parameters – such as length, mass inertia, dynamic model, and also the transformation equations – can be parameterized. This robot instance can be operated using simple movement commands.

An intuitive user interface has been developed for commissioning and operating the robot. This interface provides visualization elements based on TwinCAT HMI that enable standard-compliant operation of the robot, e.g., for jogging the individual axes or in Cartesian coordinates.

The 3D visualization, which has already been used for configuration, can be found here as an online view. Vision controls or, for example, scope controls for displaying continuous signal curves can also be embedded.

Task-specific functions can be individually displayed using an app concept. There are functions for moving the robot and for saving or editing waypoints. In another application, movement and gripper commands can be combined with wait states to create simple sequence programming. Complex motion programming can also be carried out in a similar way on the programming computer or, of course, in the familiar PLC environment, i.e., integrated into the machine programming.

As web-based display based on HTML5 is used, the interface can be displayed using a browser, e.g., on a machine panel, a tablet, or a teach pendant.

The necessary safety functions from ISO 10218-1:2025 include various safe stop functions as well as safe monitoring of the Cartesian speed of the tool center point (TCP) and exposed areas of the robot, e.g., the elbows. Beckhoff uses the TwinCAT Safety PLC for this purpose, which provides SIL3 safety logic on standard Beckhoff Industrial PCs. On this basis, function blocks are offered which monitor a safe Cartesian speed of the TCP and other exposed axes based on the safe individual axis positions of the ATRO motor modules. Application examples of these function blocks, which have been approved by a notified body, also help the user to achieve the necessary safety level for their application.

Conclusion

The end-to-end modularity of the ATRO system – both in its hardware modules and software modules for configuration, programming, operation, and safety monitoring – opens up a whole new level of flexibility for user applications. In addition to classic serial robot kinematics, exciting new configurations can be put together from the modular system by simply adding passive link modules: Due to the option of endless rotation in axis 1, workstations can be reached in the most effective way and always via the shortest route. An additional T-module after the first axis enables a 2-arm robot and thus doubles productivity; an X-module at this location results in a 4-arm robot. In many cases, however, the five or six degrees of freedom are not needed at all. A 3-axis handling arm or a 4-axis pick-and-place configuration can be assembled much more cost-effectively from the same modules. The individual applications and concepts therefore determine the solution.